Industrial Vacuum Sealer: The Complete FAQ Guide In 2025

With the continuous development of science and technology, industrial vacuum sealer is also constantly updated. In order to continuously extend the shelf life of products, reduce volume and prevent corrosion, different companies are constantly developing different industrial vacuum sealers that can meet strict health industry standards. However, do different machines have different requirements for product specifications and types? Do you know the application fields and usage methods of industrial vacuum sealers? This industrial vacuum sealer faq guide can solve all your confusion and problems with this machine. Welcome to read!

1. What Is An Industrial Vacuum Sealer?

Different from home-use vacuum sealers, an industrial vacuum sealer is a vacuum sealing and packaging machine specially used for large-scale production purposes. It is a special technology that extracts all the air from the product packaging reaching the predetermined vacuum pressure and then seals the product. The industrial vacuum sealer can be widely used in various industries. It is able to provide appropriate sealing and packaging for the product at the same time. The purpose of this packaging is for the purpose of keeping various items fresh and facilitating transportation, etc.

2. What Are The Applications Of The Industrial Vacuum Sealer?

The industrial vacuum sealer has a wide range of uses and is very convenient to use:

Food Industry

The food industry is the most widely used industrial vacuum sealer industry. Various of foods are vacuum sealed by the industrial vacuum sealers like meats, including beef, pork, etc., fruits, including mangoes, plums, etc., vegetables, including broccoli, cabbage,etc., baked goods, including cookies, breads, etc., nuts, including peanuts, sunflower seeds, etc., dry foods, including pasta, rice, etc., coffee and tea.

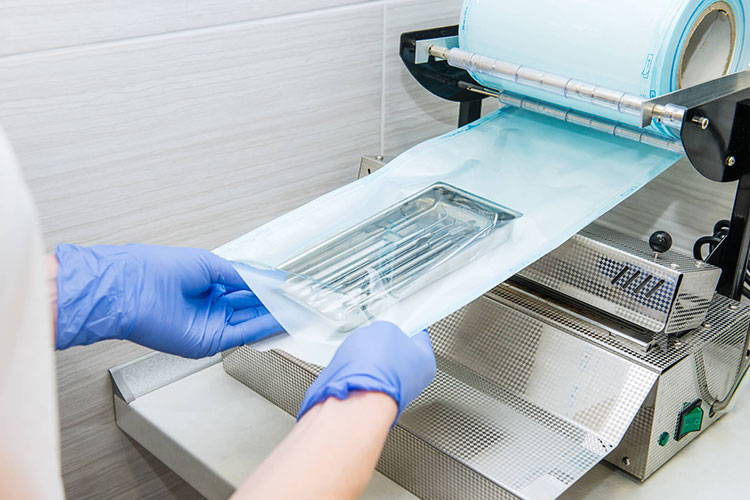

Pharmaceutical Industry

In the pharmaceutical industry, various medical devices are in great need of vacuum packaging. Because vacuum packaging can provide a safe and sterile packaging environment for medical devices. Such masks, infusion bags, sampling tubes, swabs, isolation gowns, and protective clothing can all be packed with vacuum packaging machines. Since the quantity of pharmaceutical products is relatively large and the space's cleanliness requirements are relatively high, the application prospects of industrial vacuum sealers in the pharmaceutical industry are very broad.

Cosmetics Industry

The vacuum packaging of cosmetics can completely isolate the contact between the contents and the air, so as to prevent the product from being oxidized and deteriorating due to contact with the air, and breeding bacteria, like creams, lotions, sanitizers, etc.

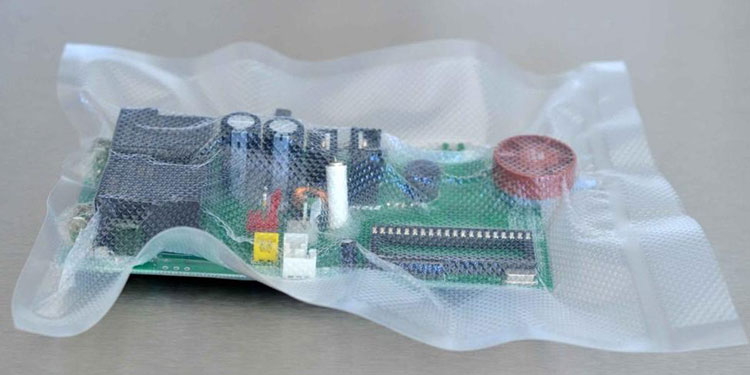

Electronic Industry

In order to facilitate the protection and transportation of electronic products, the industrial vacuum sealer is widely used in batteries, chips, circuit boards, electronic components, power supplies, switches, sensors, etc. The vacuum sealing can bring a dry and safe storage environment to electronic equipment and components, and facilitate future packaging and transportation.

3. What Products Are Mainly Applied By The Industrial Vacuum Sealer?

Frozen Foods

Almost all frozen foods are using the industrial vacuum sealer. Its purpose is to extend the shelf life of frozen foods and to ensure the freshness of frozen foods. It provides a safe, sterile environment for frozen foods and greatly offers convenience for enterprises.

Grains

All grains are using the industrial vacuum sealer. This not only prolongs the shelf life of grains but also facilitates the transportation of grains. In the past, grains were usually packaged in bags, and the shelf life was only about 6 months. Through vacuum sealing, the shelf life of grains can be greatly extended to 2 years.

Face Masks

The whole world has experienced the epidemic for about 2 years, and the demand for face masks is relatively large. Nowadays, most face masks are packaged by vacuum sealing, which can greatly prevent virus intrusion and pollution.

Surgical Instruments

The sterility requirements of surgical instruments are the most stringent because it is necessary to ensure that the patient will not be affected by bacteria during the operation and reduce the effect of the operation. All hospitals will require surgical instruments to be vacuum-packed after undergoing strict disinfection. This allows surgical instruments to be kept 100% in a sterile environment.

Rubbers

Many soft tubes made of rubbers applied the industrial vacuum sealer for longer storage and anti-bacterial. Because different rubber will be used in different fields. If this rubber is used in the medical field, the requirements for a sterile environment are very high.

Electronic Components

Today's electronic components are designed to be very small and sensitive. This fits them in a smaller space and facilitates people's use. Then, the biggest worry about electronic components is moisture and scratches. Therefore, the packaging provided by the industrial vacuum sealer can prevent them from getting wet or being damaged during storage and transportation.

4. Are There Any Products That Can Not Be Applied By The Industrial Vacuum Sealer?

Are there any products that can not be applied by the industrial vacuum sealer? Yes, varying for different reasons:

Liquids

Liquids are generally not suitable for vacuum packaging. Vacuum packaging machines are generally placed in bags manually. If the liquid is filled, the liquid cannot stand up and is easy to spill, which greatly reduces the packaging liquid. The main working principle of vacuum packaging is to extract all the air in the package. If the temperature of some liquids does not drop, more gas will be generated after vacuum packaging, which will cause air leakage in the bag.

Active Products

If you want to keep the product alive like fish, seeds, etc., the product must have oxygen to stay alive. After the industrial vacuum sealer pumps out all the air in the packaging bag, it will cause the materials to lose their activity.

5. Do You Need Special Bags For The Industrial Vacuum Sealer?

During the sealing and packaging process, the industrial vacuum sealer requires special bags for different materials:

Applicable Industry of Vacuum Sealer Bags

All vacuum bags are suitable for materials requiring special protection or barrier to gas and moisture. Not only in the food industry but also in other industries, this special vacuum bag is also suitable, for example in the packaging of bulk goods, electronic products, or machine parts.

Material of Vacuum Sealer Bags

This special vacuum bag comes in a variety of thicknesses and sizes for you to choose from. It adopts strong PA/PE barrier film material, which can provide the greatest guarantee for your safe transportation.

Advantages of Vacuum Sealer Bags

This special bag is lightweight, safe, and comes in direct contact with food. The bag's body is strong, and objects with pointed or sharp edges can also be packed in this sturdy bag. The bag reliably prevents moisture or gas from penetrating or escaping. And reduce the packaging volume of your items.

6. What Are The Benefits Of The Industrial Vacuum Sealer?

Industrial vacuum sealers can offer you various benefits:

Reduce Waste

Refrigerators and additives keep food, medicines, and other items fresh for a limited amount of time, and some items are not well suited for freezing or keeping fresh. So, to avoid food waste, a vacuum sealer is an excellent way to eliminate waste.

Longer Shelf Life

The purpose of the industrial vacuum sealer is to extend the shelf life and freshness of food. The important factors for the quality and freshness of materials are water and air. The industrial vacuum sealer can completely isolate air and moisture during the process of packaging and sealing.

Anti-bacterial

The most important thing for all medical equipment is to prevent the invasion and growth of bacteria. The industrial vacuum sealer can completely isolate the oxygen and moisture needed by bacteria by evacuating the air in the packaging bag. In this way, the shelf life of medical equipment can be greatly extended.

Food Quality

Vacuum sealer keeps food fresher to a higher degree and for a longer period of time than traditional storage methods. Likewise, it protects food from freezer burn and reduces dehydration which can affect flavor. This greatly ensures the quality of food.

7. What Is The Working Principle Of The Industrial Vacuum Sealer?

The working principle of the industrial vacuum sealer is relatively simple and easy to operate:

Working Principle Of The Industrial Vacuum Sealer -photo credits: webstaurantstore

- First, you need to choose a suitable vacuum seal bag, and put the items that need to be vacuum packed into the bag;

- Leave at least 2 inches of space between the item and the top of the bag for the closure;

- Then align the sealed end of the bag with the sealing strip of the industrial vacuum sealer;

- Make sure the bag is laid flat and completely spread out;

- Gently lower the lid of the vacuum sealer and make sure the lid is securely locked;

- Press the "start" button and wait for the machine to start automatic vacuum packaging and sealing;

8. What Are The Main Components In The Industrial Vacuum Sealer?

The main components in the industrial vacuum sealer include:

Main Components In The Industrial Vacuum Sealer -photo credits: kbtfoodpack

①Chamber Lid

The chamber lid is used to provide a safe vacuum environment for the product during the vacuuming process. Once the lid is tightly sealed, the vacuuming process can begin.

②Handles

The handles are used to control the chamber lid. When the vacuum sealing is started and finished, you need to control the handles to open the chamber lid or close the chamber lid.

③Silicone Strips

The silicone strips are applied in the sealing part of the industrial vacuum sealer. The silicone strips have the function of insulation and heat insulation. When the package is vacuumed and sealed by heat plastic, the silicone strip can ensure the cleanliness and beauty of the edge of the plastic seal.

④Connecting Rod

The connecting rod can connect the machine body with the chamber lid. Generally, the double-chamber vacuum packaging machine is equipped with four connecting rods, which is convenient for the operator to use.

⑤SUS304 Frame

The frame part is all made of SUS304 stainless steel. This material is a food-grade material, which not only can directly contact food, but also facilitates later maintenance and cleaning.

⑥Emergency Stop

When the machine needs to be braked urgently when an unexpected situation occurs during use, you need to use this button to stop the machine from running. Among them, emergency situations include but are not limited to machine failure, overflow of packaging bags, debris entering the machine, etc.

⑦Vacuum Pump

The vacuum pump is capable of helping the industrial vacuum sealer generate a partial or low-pressure vacuum by pushing gas or air molecules out of a sealed chamber. Different types of industrial vacuum sealers require different capacities of vacuum pumps.

⑧Control Panel

The control panel is equipped with the "start" and "stop" buttons for you to control. There is a data display on the panel. The screen can display the time and pressure index that your items need to be vacuumed.

⑨Wheels

The wheels with brake and anchor bolts can help you move the industrial vacuum sealer. This is convenient for your use, cleaning, and maintenance.

9. What Are The Types Of Industrial Vacuum Sealers?

There are various types of industrial vacuum sealers for your choice:

Tabletop Industrial Vacuum Sealer

Tabletop industrial vacuum sealer is suitable for smaller products' sealing and packaging. It is suitable for use on the bench and is easy to clean and maintain. The tabletop industrial vacuum sealer has an invisible cover for easy inspection while in operation.

Mobile Industrial Vacuum Sealer

The mobile industrial vacuum sealer is designed with floor casters for easy floor use and is ready to move. This mobile industrial vacuum sealer generally has a higher capacity and can pack more or larger items in a sealing and packaging cycle. This model is convenient for you to move to different areas at will.

Single Chamber Vacuum Sealer

The single-chamber vacuum sealer has a stainless steel cover with a flat stainless steel chamber with a viewing window. There are also movable rollers. These chamber vacuum sealers feature digital controls and two quick-change sealing bars for packaging multiple products per cycle.

Double Chamber Vacuum Sealer

The double-chamber industrial vacuum sealer is double-chamber designed so that you can use the first chamber while loading the second chamber. This model is suitable for some medical device manufacturers. And this model requires two operators to use it simultaneously. It is durable and easy to maintain, clean, and operate.

Nozzle Vacuum Sealer

The nozzle vacuum sealer is equipped with an internal vacuum pump and a retractable nozzle system made of stainless steel. It does not require an air compressor, just connect the power cord to use. This industrial vacuum sealer is suitable for small offices, shops, etc.

Impulse Industrial Vacuum Sealer

Impulse Industrial Vacuum Sealer -photo credits: pacmachinery

The impulse industrial vacuum sealer is suitable for heavy-duty vacuum sealing. It can be used for vacuum, gas purging or modified atmosphere packaging applications. It features an "open head design" for quick and easy bagging. This machine is suitable for high-volume packaging applications and increases the speed and flexibility of the machine.

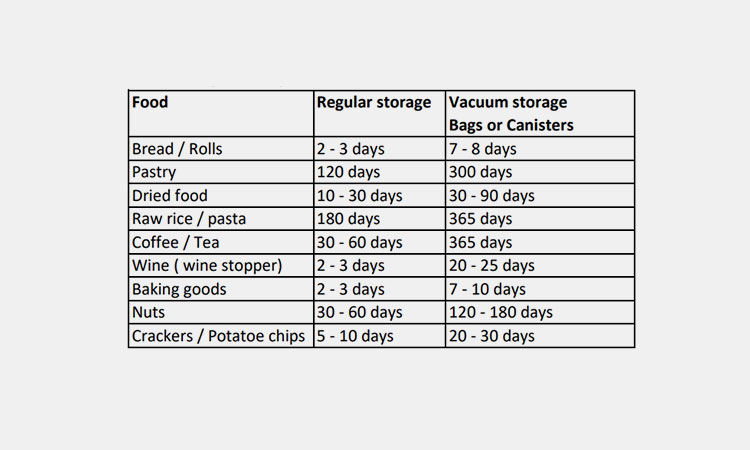

10. How Long Does Vacuum Sealed Product Last?

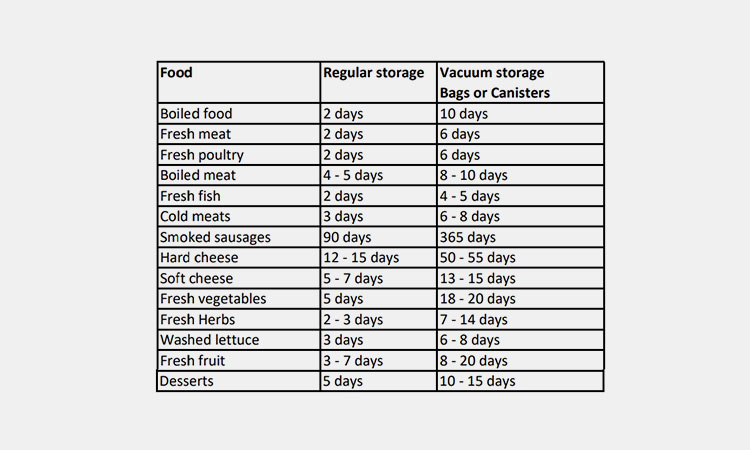

Whether the material is refrigerated or stored at room temperature, using an industrial vacuum sealer can prolong the storage time of the material by about 5 times compared with ordinary storage methods:

Let's take the food for example. Most of the foods are stored in three ways, including in the freezer, in the fridge, and in the pantry. The normal storage life expectancy is different in different ways.

Storage Life Expectancy In The Pantry

Storage Life Expectancy In The Pantry -photo credits: foodvacuumsealers

The storage time of food is not only related to the storage method but also to the food itself. Generally, pantry storage foods are foods rich in water and relatively low in water, such as dry food and dried fruits.

Storage Life Expectancy In The Fridge

Storage Life Expectancy In The Fridge -photo credits: foodvacuumsealers

Some completely processed or semi-processed foods must be stored fresh. After this kind of food is vacuum-packed, putting it in the refrigerator can increase the preservation time by about 5 times.

Storage Life Expectancy In The Freezer

Storage Life Expectancy In The Freezer -photo credits: foodvacuumsealers

Any food can be frozen. In order to avoid damaging the original taste of food due to prolonged freezing, vacuum packaging is the best way.

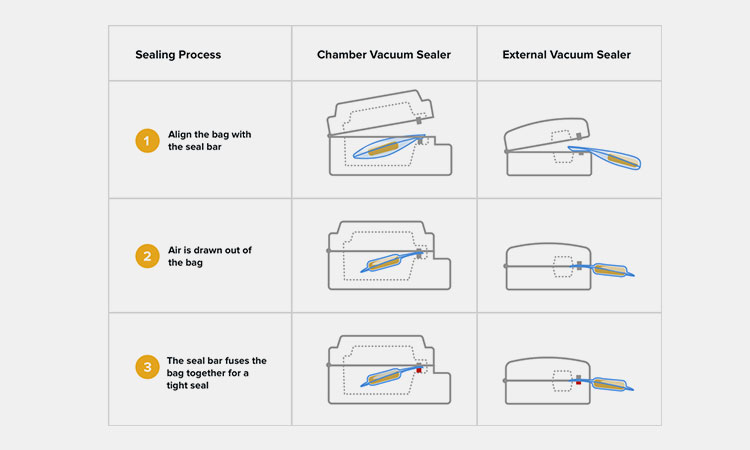

11. Chamber Industrial Vacuum Sealer VS External Industrial Vacuum Sealer

What Is A External Industrial Vacuum Sealer?

Different from the chamber industrial vacuum sealer, the external industrial vacuum sealer applies the vacuum packaging method that directly exposes the package to the outside without a chamber vacuum chamber.

Functions

The Chamber industrial vacuum sealer only has one function of vacuum packaging, but the external industrial vacuum sealer has two functions vacuuming or inflating. Inflating means that some materials may need nitrogen during the packaging process, so the external industrial vacuum sealer can inject nitrogen into the packaging while vacuuming.

Features

The chamber industrial vacuum sealer is limited by the size of the chamber. The external industrial vacuum sealer has no chamber, so it is more suitable for vacuum packaging items that are not limited by volume.

Working Principles

The external industrial vacuum sealer uses the method of air suction to evacuate the air in the package. And the chamber industrial vacuum sealer uses the vacuum pump to evacuate the air in the package.

Operations

External Industrial Vacuum Sealer Operations -Photo Credits: pacmachinery

Once the machine starts to operate, the chamber industrial vacuum sealer barely requires user operation; the external industrial vacuum sealer requires the user to hold and control the whole process.

Prices

The chamber industrial vacuum sealer is generally more expensive than the external industrial vacuum sealer.

12. How To Choose An Industrial Vacuum Sealer For Your Business?

An industrial vacuum sealer is necessary, but not choosing the right one can also be a waste of your time and money. You can consider the following points:

Machine type

When purchasing a suitable industrial vacuum sealer, you need to know the type of vacuum sealer. There are three types of Industrial vacuum sealers: home vacuum sealer type, chamber sealer type, and nozzle sealer type:

Home Vacuum Sealer Type

Mainly for domestic use, the models are very small, suitable for small professional kitchens, and not suitable for vacuum packaging of large items;

Chamber Vacuum Sealer Type

A vacuum is created in the chamber, evacuating the air from the sealed bag. Model designs are more complex and more expensive. large capacity. Even items such as glass bottles can be vacuum-packed.

Nozzle Vacuum Sealer Type

It is suitable for vacuum packaging of bulky items, such as clothes, quilts, hardware, large silicone materials, etc.

Pump Type

Different industrial vacuum sealers are equipped with different pump types. There are generally two types of pumps: oil pumps or piston pumps. The oil pump is quiet and the cooling time is short, the disadvantage is that the oil must be changed regularly. The piston pump is noisy and takes a long time to cool down.

Compressor

A powerful compressor means faster sealing times and more efficient suction. Therefore, choosing a model with a strong compressor can greatly improve your vacuum sealing efficiency.

Safety

When using an industrial vacuum sealer, focus on the experience of using it. Including packaging time, whether the machine is flat, the sealing degree of the model, etc.

Warranty

Although most of the machines are solid and reliable, problems will still occur after long-term use. Therefore, manufacturers who can promise for a longer period of time are obviously more reliable.

13. What Are The Troubleshooting For The Industrial Vacuum Sealer?

Why sometimes vacuum sealing does not work? After repeated boot attempts, the machine has no effect. Here is the troubleshooting list for you:

Check Your Bag

A wet bag or overfilled bag will affect the effect of vacuum sealing. You need to dry your bag or do not overfill your bag before vacuum sealing.

Replace Your Sealing Strip

Sometimes in the process of vacuum sealing, the sealing strip will have aging problems. At this time, you need to replace your sealing strip in time.

Not Enough Suction

Not enough suction is caused by placing too many bags in the airtight chamber. Make sure you're not stacking too many bags at once during the process, and that dust and dirt aren't collecting between the lid and seal.

Improper Sealing

Improper sealing methods will cause severe results. When vacuum sealing with some liquid or oil, pay attention to placing the packaging bag correctly to prevent the liquid or oil from seeping out.

Conclusion:

Vacuum sealing is one of the best ways to reduce waste and extend the product's shelf life. After applying the industrial vacuum sealers, you can get all your business fast with high capacity. This industrial vacuum sealer faq guide covers all the questions you need to know. If there are any other things you are not sure about, just browse our official website: https://www.allpackchina.com/, or just consult our customer services!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours