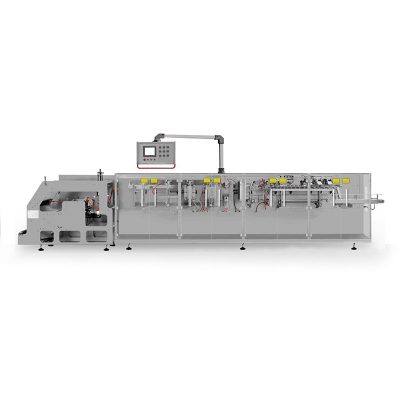

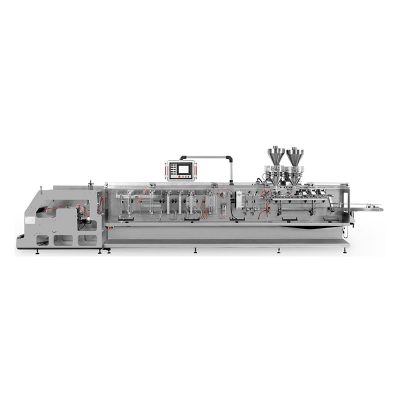

Aipak Automatic vacuum pickles premade pouch filling machine is suitable for vacuum packing of various irregular materials, bean products and pickles, such as bulk dried beans, shredded mustard, sliced mustard, sauerkraut, sour beans, dried tea, large dried beans, fried chicken, spicy chicken, marinated eggs, three section wings, etc.

FEATURE:

- The automatic bag type vacuum packaging series can meet various functions and materials.

- The rotary automatic bag feeding vacuum packaging machine consists of two separate rotating bodies (filling system and vacuum system respectively). The filling system is intermittent rotation operation and vacuum system is continuous rotation movement.

- Quickly change the packing bag specification, and the width of the automatic bag feeding device can be adjusted automatically and once.

- It meets the hygiene standards of food processing machinery. The parts on the machine contacting with materials or packaging bags are processed with stainless steel or other materials meeting the food hygiene requirements to ensure the hygiene and safety of food.

- Easy to clean, and the vacuum room can be cleaned.

- The packaging material loss is low. The machine uses prefabricated packaging bags, perfect packaging pattern and good sealing quality, thus improving the product grade. No cutting and sealing, the bag can be recycled. It does not waste the bag.

- It is convenient to operate, and advanced PLC plus pod (touch screen) electrical control system is adopted. The man-machine interface is friendly and easy to operate. The angle and time of pneumatic components can be adjusted automatically.

- Sealing temperature monitoring function, if the heating pipe or electric couple is damaged, it will be displayed in the touch screen to alarm.

- External vacuum pump.

DATA SHEET:

| Model | APKRL-GD-ZK130J | APKRL-GD-ZK160J | APKRL-GD-ZK200J |

| Working Process | 1. On Bags 2、Opening 3、Cutting 4. Adding liquid 5. Reserving 6. Reserving 7. Crossing bag 8. Reserving → (vacuum)

1. Connect the tape 2. Close the cover 3. Primary vacuum 4. Secondary vacuum 5. Tertiary vacuum 6. Fourth vacuum 7. Seal 8. Seal cold cut 9. Vent 10. Open the cover and take out the bag |

||

| Sealing style | Instant heating sealing and instant cold cutting after sealing to ensure beautiful sealing | ||

| Packing speed | 35~60 Bags/min(By Product Characteristics) | ||

| Packaging Materials | Aluminum foil bags, paper bags, nylon bags and other film coated bags | ||

| Packaging specifications | W:50mm-130mm L:80mm-200mm | W:80mm-160mm L:80mm-210mm | W:130-200mm L:≤300mm |

| Total Power | 5.5KW | ||

| Drive power | 380V 50HZ | ||

| Overall Dimensions | 2100mmx1400mmx1600mm(L*W*H)not include lifter | 2420*1700*1800mm | |

| Weight | 2.2T | ||

| Use environment | Room temperature 10-40 ℃, 30-90% RH, no dew, no corrosive gas, no dust and other harsh environment | ||

Reviews

There are no reviews yet.