Shrink Sleeve Machine: The Complete Buying Guide In 2025

Businesses must have packaging that only safeguards their goods in today’s cutthroat market but also helps to build their brand. For this reason, shrink sleeve machines have gained popularity. For a wide range of items, they are intended to offer a reliable and tamper-proof labeling option.

This article offers helpful information regarding shrink sleeve machines if you’re thinking about implementing shrink sleeve machines into your product packaging process. Discover more about shrink sleeve machines by reading this guide.

1.What is shrink sleeve machine?

Shrink Sleeve Machine-Photo Credit: Afmsleeves

Shrink sleeve machines are one of the most useful types of packaging machines, used to apply labels on various product containers, bottles, jars, cans, etc. It is mainly used in industries like food and beverages, cosmetics, pharmaceuticals, and consumer goods. The shrink sleeve machine is the most efficient and cost-effective way to apply product labeling and branding, to enhance business visibility and marketability.

These machines have high-quality graphics, intricate designs, and branding information. With this feature, it can generate high-definition 360-degree coverage labels for brand enhancement. Moreover, shrink sleeve machines provide cost-effective and sustainable labeling solutions as they minimize material waste and reduce the need for additional packaging layers.

2.What are the applications of shrink sleeve machines?

Shrink sleeve machines are used to apply shrink sleeve labels to a wide range of products in the packaging industry. Here are some of the applications of shrink sleeve machines:

Beverage Industry:

Shrink sleeve machines are widely used in the beverage industry to apply shrink sleeves to bottles and cans of various sizes and shapes. Shrink sleeves can be used to provide product information, branding, and promotional messages.

Food Industry:

Shrink sleeve machines are used in the food industry to label food products such as jars of jams, sauces, and condiments, as well as packaged snacks, frozen foods, and baked goods.

Cosmetics Industry:

Shrink sleeve machines are used in the cosmetics industry to apply shrink sleeves to cosmetic products such as shampoo bottles, lotion bottles, and makeup containers.

Pharmaceutical Industry:

Shrink sleeve machines are used in the pharmaceutical industry to label medicine bottles, tubes, and containers, providing information about dosage, instructions, and safety warnings.

Automotive Industry:

Shrink sleeve machines are used in the automotive industry to label automotive parts such as batteries, filters, and hoses. Due to their longevity and tolerance to extreme climatic conditions, shrink sleeves are frequently utilized in the automotive sector.

They are made to survive exposure to chemicals often used in automotive applications, including lubricants, greases, fuels, and other chemicals.

Household Products:

Shrink sleeve machines are also used in the household products industry to label products such as cleaning supplies, detergents, and air fresheners. Because they are waterproof, tear-resistant, and able to tolerate exposure to harsh chemicals, they are especially helpful for labeling cleaning supplies, detergents, air fresheners, and other home products.

Electronics Industry:

Shrink sleeve machines are used in the electronics industry to label products such as batteries, chargers, and electronic accessories.

3.What are the benefits of a shrink sleeve machine?

- 360-Degree Branding:

Shrink sleeve machines provide plenty of room for the display of graphics, branding, and product information on all sides of the item.

Shrink sleeve machines can provide the goods distinctive and captivating appearance that will make it stand out on store shelves.

Additionally, promotional messaging or QR codes that lead to more in-depth product details or promotions can be printed on shrink sleeves.

- Versatile:

Shrink sleeve machines are versatile, working with items of all sizes and shapes, from small bottles to big containers.

Glass, plastic, and metal are just a few of the materials that can be wrapped in shrink sleeves.

Shrink sleeves can be printed with custom designs and colors, allowing for a wide range of branding options.

- Cost-Effective:

In comparison to other labeling methods like direct printing or labeling machines, shrink sleeves may be produced in big quantities at a reduced cost.

Shrink sleeve machines simplify packaging and reduce waste by doing away with the need for extra labels or packaging materials.

Additionally, shrink sleeve machines are quick and simple to apply, which lowers labor costs and boosts productivity.

- Durability:

Shrink sleeve machine provides a strong, protective coating that can tolerate challenging environmental factors like moisture or temperature changes.

Shrink sleeve machines can shield the goods from deterioration during handling or transit, lowering product loss and raising client satisfaction.

Additionally, shrink sleeves can be made to resist scuffs and scratches, preserving the product's appearance and branding over time.

4.What are the types of shrink sleeve machines?

There are several types of shrink sleeve machines available in the market, and each one of them is designed for specific product packaging needs. Some of the most common types of shrink sleeve machines which include.

- Semi-Automatic Shrink Sleeve Machine:

Semi-Automatic Shrink Sleeve Machine-Photo Credit:Ucpack

This type of machine is suitable for moderate-volume production which includes an automatic sleeve feeder that feeds the sleeves onto the product and a heat tunnel for shrinking. They are made to automate the majority of the labeling process, these machines only need minimum manual labor.

They provide a cost-effective labeling solution that can increase labeling productivity and lower labor expenses, making them perfect for firms with moderate labeling requirements.

- Automatic Shrink Sleeve Machine:

Automatic Shrink Sleeve Machine-Photo Credit:Ucpack

This machine is suitable for mass production. It includes an automatic sleeve feeder with product handling aisles and a heat tunnel for label shrinkage. The machine can handle multiple types of shapes and sizes and can operate continuously without manual intervention. It is entirely automated, these machines don't need any manual labor to do any of the labeling tasks, including labeling cutting, and shrinking.

They ensure that the labeling is done correctly since they are quite effective and provide a high level of precision and accuracy. Automatic shrink sleeve machines are a cost-effective labeling solution for companies with significant labeling demands since they can process large numbers of products quickly.

- Premade Shrink Sleeve Machine:

Premade Shrink Sleeve Machine-Photo Credit:ShrinkPack

The premade shrink sleeve machine works by using a feed system to transport pre-printed sleeves to the labeling station. The containers are then fed into the machine and the sleeves are applied using heat to shrink and conform to the shape of the container. The end result is a labeled product that is attractive, durable, and tamper-evident.

- Form Fill Shrink Sleeve Machine:

Form Fill Shrink Sleeve Machines-Photo Credit:Packing Machine

This machine forms shrink sleeve material into a tube around the product using a form fill shrink sleeve machine, which then applies heat to shrink the material. In order to prevent wastage of sleeve materials and increase label design flexibility, form-fill shrink sleeve machines may produce the sleeve material as needed from a roll of flat film.

- Combination Shrink Sleeve Machine:

Combination Shrink Sleeve Machine-Photo Credit:James Dawson Enterprises

This machine is designed for multiple tasks such as labeling, filling, and capping. They are made to be adaptable and are perfect for enterprises in a variety of industries, including food and beverage, cosmetics, and pharmaceuticals which can handle a wide range of container shapes and sizes.

Combination shrink sleeve machine may lower labeling expenses and boost labeling output. They provide a high level of accuracy and precision, guaranteeing proper labeling. It is suitable for large-scale production and is most commonly used in the food and beverage, pharmaceutical, and cosmetic industries.

- Vertical Shrink Sleeve Machine:

Vertical Shrink Sleeve Machine-Photo Credit:ALLMA

This machine is designed for labeling tall products like cans and bottles and jars that are filled and labeled while standing upright. Vertical shrink sleeve machines attach shrink sleeve labels to the products using a roll-fed film. The label is applied by the machine, which also shrinks and trims it to fit the product's shape.

These devices ensure that the labeling is done correctly with a high degree of precision and accuracy. They are cost-effective labeling solutions since they are very effective and can quickly label vast quantities of things. The versatility of vertical shrink sleeve machines allows them to handle a variety

- Horizontal Shrink Sleeve Machine:

Horizontal Shrink Sleeve Machine-Photo Credit:AXON

This machine is designed for labeling wide products like flat boxes, cartons, and containers by positioning the sleeves horizontally onto the product and shrinking the label by passing through the heat tunnel. Shrink sleeve labels are applied to the products using horizontal shrink sleeve machines and roll-fed film. The label is applied by the machine, which also shrinks and trims it to fit the product's shape.

It ensures labeling is done correctly with a high degree of precision and accuracy. They are cost-effective labeling solutions since they are very effective and can quickly label vast quantities of things. The versatility of horizontal shrink sleeve machines allows them to handle a variety of products.

- Steam Shrink Sleeve Machine:

Steam Shrink Sleeve Machine-Photo Credit:Accraply

Machines that use steam to shrink the label onto the goods are known as steam shrink sleeve machines. It can work with a wide range of product shapes and sizes and is renowned for its accuracy and consistency in label application. The label will also be perfectly shaped to fit the product's curves thanks to the steam.

- Electric Shrink Sleeve Machine:

Electric Shrink Sleeve Machine-Photo Credit:Focusonltd

This machine can be used in a variety of industries, such as food and beverage, cosmetics, and pharmaceuticals, due to its versatility and ability to handle a wide range of container shapes and sizes. Electric shrink sleeve machines are preferred for companies needing a dependable and effective labeling solution because they are simple to use and maintain.

With the use of electricity, the label is shrunk onto the product. It is a great choice for high-volume production lines because of its efficiency and quickness. It can also work with a variety of label materials, such as PVC, PETG, and OPS.

Infrared Shrink Sleeve Machine:

Infrared Shrink Sleeve Machine-Photo Credit:Peichaun

An infrared shrink sleeve machine is a kind of packaging device that shrinks and molds heat-sensitive shrink sleeves to the shape of a container using infrared radiation. It boosts production and lowers energy costs via fast heating and shrinking times are made possible by infrared heating technology.

It has constant and uniform shrink which precise temperature controls and modifies in accordance with the type of shrink sleeve material and the size and shape of the container. It reduces damage via infrared heat source is non-contact because it doesn't make direct touch with the container and lowers the chance that the product may sustain harm.

5.What is the difference between premade shrink sleeve machines and form fill seal shrink sleeve machines?

The most prominent difference between premade shrink sleeve machine and form fill seal shrink sleeve machine is the pattern of application of subsequent labels and formation of sleeves on the products.

- Premade Shrink Sleeve Machines:

The premade sleeves are loaded in the machines and then the product is allowed to be labeled into the sleeve. The machine then uses the heat for shrinking the label to conform required shape and size of the product. This type of labeling can only be used for lower-production runs, where limited pre-made sleeves are required.

- Form Fill Seal Shrink Sleeve Machines:

The sleeves are formed in the machine itself by using a continuous roll of the stack. The film is formed and applied onto the product and then sealed to create a sleeve. Then the machine uses a heat tunnel to shrink the sleeve and conform it according to the shape of the product. This highly flexible method is used for mass production in which machines customize the labels specifically.

6.How does shrink sleeve machine differ from normal labeling machine?

Following are some key differences between shrink sleeve machines and typical labeling machine.

Shrink Sleeve Machine VS Labeling Machine-Photo Credit:AllenPack&Allpack

- Labeling Technique:

A shrink sleeve machine applies shrink sleeves to the container, which conforms to the shape of the container when heated as compared normal labeling machine uses pressure-sensitive labels or self-adhesive labels to apply them to the surface of the container.

- Label Coverage:

Shrink sleeve machines provide 360-degree coverage, covering the entire surface of the container. Comparatively, normal labeling machine applies the label to the front, back or sides of the container, leaving the top and bottom uncovered.

- Tamper-Evidence:

Tamper-evidence protection is provided by shrink sleeve machines unlike normal labeling machines. When a shrink sleeve is applied to a container, it seals by a tamper-evident barrier that prevents unauthorized access to the product.

- Appearance:

Shrink sleeve machine offers a more visually appealing finish as compared to normal labeling. Shrink sleeves offer a smooth, wrinkle-free surface that conforms to the shape of the container, providing a high-quality, attractive finish.

- Compatibility:

Shrink sleeve machines are generally more versatile and can handle a wider range of container shapes and sizes, whereas normal labeling machine is limited and typical without creative options for brand enhancement.

In summary, a shrink sleeve machine offers more advanced labeling and packaging capabilities compared to a normal labeling machine. It provides full 360-degree coverage, tamper-evidence protection, improved appearance, and better compatibility with multiple range of sizes and shapes of the products.

7.What is the working principle of a shrink sleeve machine?

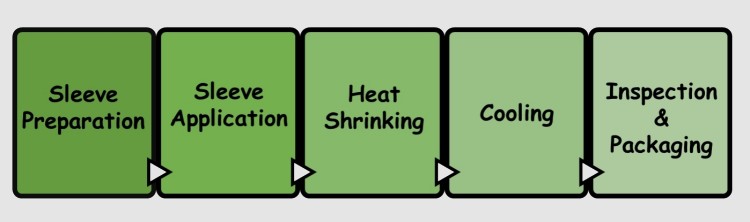

The working principle of a shrink sleeve machine involves three main steps: sleeve preparation, sleeve application, heat shrinking, cooling and inspection & packaging.

- Sleeve Preparation:

Firstly, shrink sleeve material is designed and printed, then cut according to the required length and shape. Then sleeves are stored as rolls and stacks, completely depending on the type of machine.

- Sleeve Application:

Secondly, the conveyor belt pulls the item to be labeled through the apparatus. The machine accepts the sleeve material and cuts it to the right length for each product. The product is then covered with the sleeve, either by pulling it over the thing or by wrapping it around it. The sleeve is subsequently secured in position using a variety of techniques, including a hot air blower.

- Heat Shrinking:

At last, a heat tunnel, heated air is used to shrink the sleeve around the object after it has had a sleeve attached. The sleeve forms firmly to the product's contour as a result of the heat, producing a label that is seamless and tamper-evident. After cooling the product to secure the sleeve, it can be examined and packaged for shipping.

- Cooling:

The labeled product is still hot and bendable after the heat-shrinking procedure. In order to maintain the integrity of the sleeve and ensure that it fits the product's shape firmly, it must be cooled down. The product is typically cooled by passing it through a cooling chamber or tunnel that pushes cold air onto the labeled product to hasten cooling.

- Inspection & Packaging:

The labeled product is examined for quality control reasons to make sure the sleeve with properly labeled sleeve applied. Several techniques are used during the inspection step, such as visual inspection, barcode scanning, and automatic rejection of faulty products.

8.What are the components of shrink sleeve machines?

The Shrink Sleeve Machine has several components that facilitate efficient and accurate labeling:

Shrink sleeve machines are devices used to apply shrinkable film sleeves to a variety of products, such as bottles, cans, and jars. Here are the explanations of some of the key components of a typical shrink sleeve machine:

Label Holder: This is the component that holds the roll of shrink sleeve labels that are to be applied to the products. The label holder is typically located at the top of the machine and can be easily accessed for loading and unloading the label rolls.

Film Cutting Mechanism: This is the part of the machine that cuts the shrink sleeve film to the appropriate size for the product. The cutting mechanism is typically located near the label holder and can be adjusted to accommodate different product sizes and label lengths.

Film Feeding Mechanism: The film feeding mechanism is responsible for feeding the shrink sleeve film from the label holder to the cutting mechanism. This mechanism typically uses a series of rollers and guides to ensure that the film is properly aligned and tensioned for cutting.

Film Pulling Mechanism: Once the film has been cut to the appropriate size, the film pulling mechanism takes over to pull the cut label onto the product. This mechanism typically uses a series of rollers and guides to ensure that the label is applied smoothly and without wrinkles or bubbles.

Heat Tunnel: The heat tunnel applies heat to the shrink sleeves, causing them to shrink and conform to the shape of the products.

Motor:The motor is the power source for the shrink sleeve machine, driving the various mechanisms and components that make up the machine.

Operation Panel:The operation panel is where the operator controls and monitors the operation of the machine. It typically includes controls for adjusting the speed of the machine, as well as monitoring features to ensure that the machine is operating properly.

Brush:The brush is a component that is used to smooth out any wrinkles or bubbles in the shrink sleeve label as it is being applied to the product. The brush is typically located near the film pulling mechanism and can be adjusted to accommodate different product sizes and label shapes

Conveyor:The conveyor is an essential component of a shrink sleeve machine as it is responsible for transporting the products through the machine The conveyor typically consists of a belt made of rubber or other durable material that is powered by a motor, and a series of rollers or other devices that support and guide the belt along its path.

9.What key factors are important to consider for the selection of a shrink sleeve machine?

Selecting the right shrink sleeve machine is crucial to ensure the efficient and effective packaging of products. Here are some key factors which are need to be considered while choosing a shrink sleeve machine specifically.

- Production Speed:

The production speed of the machine should be considered in relation to the production requirements of your business. If you have high production requirements, you may need a machine with a faster production speed.

- Product Size and Shape:

The size and shape of the products that you intend to package will determine the type of Shrink sleeve machine you need. Some machines are designed for cylindrical products, while others can handle irregular shapes and sizes.

- Shrink Sleeve Material:

Shrink sleeve machines can handle different types of shrink sleeve materials such as PVC, PET, OPS, and PLA. The type of material used will depend on the product being packaged, and the desired look and feel of the packaging.

- Budget:

Finally, the budget is a crucial factor in selecting a shrink sleeve machine. Consider the upfront cost, as well as the ongoing costs associated with maintenance and operation.

By considering these factors, businesses can select a shrink sleeve machine that meets their specific packaging requirements and helps to enhance their production efficiency and profitability.

Conclusion

Shrink sleeve machines have become increasingly popular for their ability to offer a reliable and tamper-proof labeling solution for a wide range of products. This complete buying guide has provided helpful information about shrink sleeve machines, by considering the factors outlined in this guide, businesses can make an informed decision when choosing a shrink sleeve machine that meets their specific needs and budget.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide