Small Powder Filling Machine: The Complete Buying Guide In 2025

Are you in the market for an efficient and cost-effective way to package your powder products? Then a small powder filling machine may be the right solution for you. This piece of equipment makes it easy to accurately fill containers with consistent amounts of dry goods, while streamlining the production process by simplifying simple packaging tasks like measuring, filling, screw capping and labeling.

In this guide, we are going to discuss everything that you may want to know about a small powder filling machine. Keep reading to see how having a small powder filling machine could help boost both productivity and profitability in your business!

1.What Is A Small Powder Filling Machine?

A small powder filling machine is a type of equipment used to precisely fill dry powders, granules, and other powdered materials into pre-determined containers. These devices help to ensure that products are filled with the exact weight or volume of powder needed.

Also, these machines can be used to fill a wide variety of products from food items like spices to pharmaceuticals, cosmetics and industrial chemicals. These machines normally come in a range of sizes, from tabletop models to fully automated filling lines.

Moreover, small powder filling machines are an efficient way to ensure accurate and consistent fills for products, while also reducing labor costs and increasing production speeds. In addition, the cost of these machines varies depending on the size, features, and automation level desired.

2.What Are The Components Of A Small Powder Filling Machine?

A small powder filling machine typically consists of the following components:

Feeder Hopper

This component stores the powder and feeds it into the machine for filling. It is usually equipped with a vibratory hopper to ensure consistent and efficient powder flow.

Filling Nozzle

The filling nozzle is responsible for accurately dispensing the powder into each container. It is designed in such a way that it provides precision and control over the amount of powder that is dispensed.

Control Panel

This component is used to monitor all aspects of the filling process, from speed and accuracy to material usage and waste levels. This ensures that everything runs smoothly and efficiently.

Weighing Scale

The weighing scale is used to keep track of how much powder has been filled into each container. This helps to ensure consistency between batches, as well as helping to control wastage levels.

Conveyor Belt

This part moves the filled containers from one station to the next. This helps to keep the production line running smoothly and prevents any delays or disruption in the process.

3.What Are The Advantages Of A Small Powder Filling Machine?

Cost-Effective

A small powder filling machine is an affordable way to package products without compromising on quality. These machines are relatively inexpensive compared to larger models and can be used in a variety of settings. This makes them ideal for businesses with tight budgets or those who have limited space available.

Greater Efficiency

Small powder filling machines are designed to optimize efficiency and speed, allowing for more production in a shorter amount of time as compared to manual filling.

Accuracy

Small powder filling machines are equipped with precision dosage systems that enable them to accurately fill containers with a predetermined amount of powder every time, resulting in higher quality and less waste.

User Friendly

A small powder filling machine is easy to maintain and operate. They are usually simple machines with few moving parts, making them easier to troubleshoot and fix than larger models. This means you can keep your equipment running smoothly without spending a lot of time or money on maintenance.

4.What Are The Applications Of A Small Powder Filling Machine?

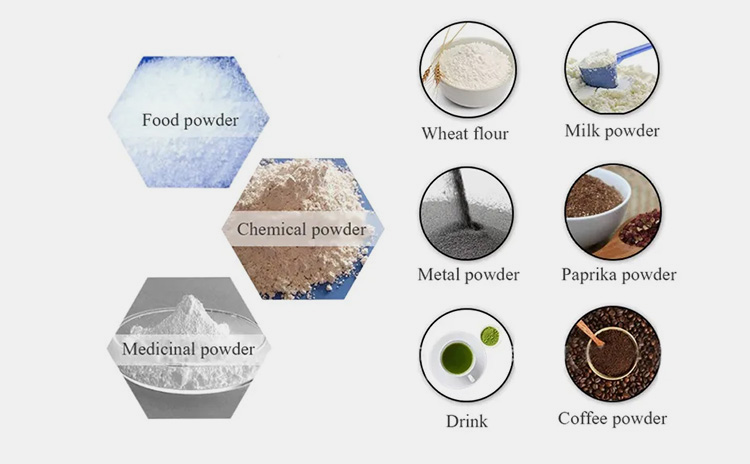

A small powder filling machine can be applied to many different industries. Here are a few examples:

Food Industry

A small powder filling machine can be used to precisely fill containers with powdered ingredients such as sugar, flour, and spices. This helps ensure accurate measurements and high-quality products.

Pharmaceutical Industry

In the pharmaceutical industry, a small powder filling machine is often used to fill bottles with powdered medicines and supplements. This device can help guarantee the accuracy of doses and reduce waste.

Chemical Industry

When it comes to the chemical industry, a small powder filling machine can be used to measure out precise amounts of chemicals for manufacturing processes. This helps ensure quality assurance in production and consistency across batches.

Cosmetic Industry

Small powder filling machines can also be in the cosmetic industry to fill containers with powders for makeup products. This helps ensure accuracy in measurements.

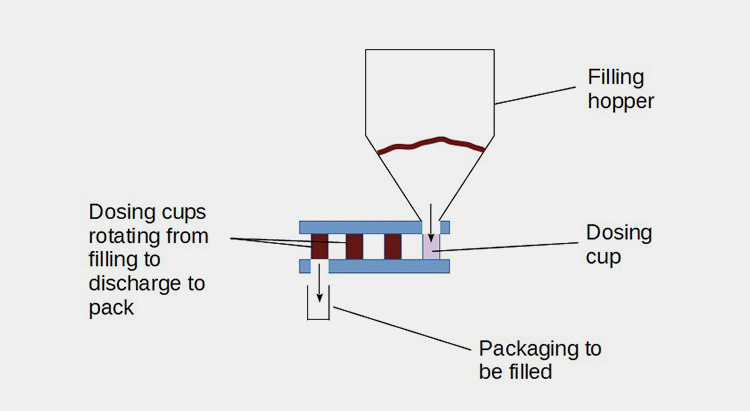

5.What Are The Working Principles Of A Small Powder Filling Machine?

The process starts when the container moves into the filler station and stops in place on the filling nozzle. Once the machine detects that the container is in position, it will activate a series of components to begin the filling process.

First, material is dispensed into the container using a series of plungers that are automatically activated. This process allows for exact amounts to be deposited into the containers. The machine will then vibrate the container to shake any excess powder off and level it out. Once this step is complete, the next container moves in place on the nozzle and the process begins again.

6.What Are The Different Types Of Small Powder Filling Machines Available In The Market?

There are several different types of small powder filling machines available on the market. These include:

Manual Powder Filling Machines

Manual powder filling machines are usually hand operated and use a dosing scoop to fill containers with precise amounts of powder. They are most suitable for low to medium production requirements, and can be used for large volumes of small batches.

Semi-Automatic Powder Filling Machines

These machines are ideal for small business with limited budget and requirement. They are also appropriate for packaging of fragile products like powders and granules. Semi-automatic powder filling machines require manual loading and unloading of containers, but the actual filling process is automated allowing great accuracy without any operator intervention.

Automatic Powder Filling Machines

These machines are fully automated and feature integrated conveyor system, filling nozzles and other accessories that enable efficient and accurate filling of product into containers. The automation ensures greater accuracy and speed as compared to manual or semi-automatic systems. Automatic powder filling machines offer the best solution for large scale production operations.

Volumetric Powder Filling Machines

These type of small powder filling machines use a volumetric dosing system to fill containers with precise amounts of powder, and are typically used for high production requirements. They are often automated and can be integrated into more complex filling systems.

Auger Filler Powder Filling Machines

Auger filler powder filling machines use an auger to fill containers with a precise amount of powder, and are designed for accurate filling of small batches. They are suitable for medium to high production requirements.

Net Weight Powder Filling Machines

Net weight powder filling machines are designed to fill a precise amount of powder or granular material into each container. These machines feature an adjustable filling range so that the operator can set the exact amount to be filled.

Vibratory Powder Filling Machines

These type of machines use vibration to fill containers with a precise amount of powder, and are suitable for medium to high production requirements. They are often automated and can be integrated into more complex filling systems.

Vacuum Powder Filling Machines

Vacuum powder filling machines use a vacuum system to fill containers with a precise amount of powder, and are suitable for low to medium production requirements. They are often automated and can be integrated into more complex filling systems.

7.What Is The Difference Between Manual Powder Filling Machines And Automatic Powder Filling Machines?

The main distinction between a manual powder filling machine and an automatic powder filling machine is the mode of operation. Manual powder filling machines require a human operator to apply force to depress a plate, which in turn dispenses a desired amount of product from the hopper. This type of machine is typically used for smaller scale filling applications and is usually more economical than an automatic machine.

On the other hand, an automatic powder filling machine requires no human operator to control it. Instead, a servo motor or pneumatic actuator controls the flow of product from a hopper into containers or packaging. This type of machine is ideal for large-scale filling applications and can fill hundreds or even thousands of containers per minute.

8.What Is the Difference Between Automatic Powder Filling Machines And Semi-Automatic Powder Filling Machines?

The primary difference between an automatic powder filling machine and a semi-automatic powder filling machine lies in the amount of manual labor required. Automatic powder filling machines are fully automated, requiring no human intervention during the process. Semi-automatic machines require some form of manual input from an operator - typically this involves loading and unloading containers, configuring settings and placing the containers in position on the machine.

When it comes to speed, accuracy, and efficiency of operation, automatic powder filling machines have a clear advantage over their semi-automatic counterparts as they complete the entire process without human input or intervention. Automatic equipment can operate continuously for long periods of time without rest, whereas manual systems require frequent operator intervention and breaks.

In terms of cost, semi-automatic powder filling machines are usually the more cost-effective option for small to medium scale operations due to their lower initial purchase price. However, in larger production environments, the costs associated with employee wages and downtime can outweigh any savings from a cheaper machine. Automatic powder filling machines tend to be more expensive to purchase but may be the most cost-effective option in the long run.

9.What Is The Difference Between A Small Powder Filling Machine And A Small Liquid Filling Machine?

The main difference between a small powder filling machine and a small liquid filling machine is in the method of dispensing the product. A small powder filling machine uses an auger or vibratory system to dispense dry materials, such as powders, granules, and pellets. Whereas a liquid filling machine uses a piston-filler mechanism to dispense liquids.

The types of products that can be processed also differ between a small powder filling machine and a small liquid filling machine. A small powder filling machine is suitable for dispensing dry or semi-dry products, such as food ingredients, detergents, chemicals, and other powdered materials. A small liquid filling machine is suitable for dispensing viscous liquids, such as beverage drinks, oils, and sauces.

In terms of capabilities and features, small powder filling machines offer a wide range of features that are not available with small liquid-filling machines. A small powder filling machine can handle products with high viscosity or very fine particles. It also offers greater accuracy in filling, as well as faster packaging speeds. On the other hand, a small liquid filling machine offers greater control over product flow rate and more precise fill volume control.

10.What Type Of Products Can Be Filled Using A Small Powder Filling Machine?

A small powder filling machine can be used to fill many types of materials. These include:

Powders

These are fine particles that can be easily dispersed in air and may include:

Milk Powder

A small powder filling machine is perfect when it comes to accurately filling milk powder into containers or bags. It can also measure the weight and dispense the correct amount each time.

Flour

Also, a powder filling machine can be used to accurately and quickly fill flour into containers or bags. The weight of the flour can be easily regulated so that each package contains the same quantity.

Coffee Powder

Cocoa powder is made from roasted cocoa beans, which are then ground into a fine powder. This type of powder can be filled with a small powder filling machine and is commonly used in baking or for making hot chocolate and other chocolate-based drinks.

Starch

Starch is also a common powder that can be filled with a small powder filling machine. It's often used in manufacturing food and medical products, as well as for industrial applications.

Spice Powder

With a small powder filling machine, you can easily fill spices of any size and texture. This type of equipment is also ideal for accurately measuring the weight of each spice package.

Tea Powder

A fine powder that has been processed from teal leaves can also be filled using a small powder filling machine. Black tea, green tea, oolong tea, and white tea can all be made with this kind of powder.

Granules

These are generally solid particles that have been formed by grinding or cutting down larger material into smaller pieces and can include grains, cereals, and certain types of plastics.

Pastes

These are thick substances that can be used for a variety of applications including food products, cosmetics, and more. ‘

Liquids

Many small powder filling machines also come with liquid filling capabilities, allowing them to work with a variety of liquids such as sauces, gravies and syrups.

11.What Type Of Packages Can Be Used With A Small Powder Filling Machine?

There are many types of packages that can be used with a small powder filling machine depending on the product being packaged and the intended use. They include:

Bottles

Glass or plastic bottles can be filled with a powder using a small powder filling machine. This is ideal for products such as supplements, vitamins or other granular products.

Cans

Tin cans with metal lids can also be used especially for larger quantities of powder. This is because they have a more rigid structure, making them great for heavier items.

Pouches

These are flexible packages that come in various sizes to accommodate a range of products and can be sealed using heat sealing or ultrasonic welding.

12.What Type Of Materials Is A Small Powder Filling Machine Made Up Of?

A small powder filling machine is typically made up of the following materials:

Stainless Steel

This is an extremely strong and durable material. It is the preferred choice of material for many small powder filling machines, as it resists corrosion and wear caused by constant exposure to powder particles, chemicals, and other substances found in a manufacturing environment.

Aluminum

Aluminum is a lightweight material that can also be used in powder filling machines. It has very strong corrosion resistance and is easy to clean and maintain.

13.What Are The Quality Compliances Of A Small Powder Filling Machine?

FDA compliance

A small powder filling machine must comply with all applicable regulations under the Food and Drug Administration (FDA). This includes ensuring that any materials used in the production process are safe for food contact and meet safety standards.

UL listing

Many of the components used to manufacture a small powder filling machine must be UL listed, meaning they have been tested and certified for safety by a third-party organization. This includes the motor, wiring, and any other electrical components that may be used in the machine.

Compliance with local regulations

Depending on where the small powder filling machine is being used, it must meet all applicable local regulations as well. This could include requirements from the Occupational Safety and Health Administration (OSHA) or other government agencies.

Quality control systems

A small powder filling machine must be equipped with a quality control system to ensure that every batch of product is filled correctly and safely. This could include visual inspections, checking for particle size consistency, and other tests to confirm that the powder is safe for use.

14.What Are The Considerations Before Purchasing A Small Powder Filling Machine?

Accuracy

As accuracy is key when it comes to filling powder, look for a model with a precision mechanism to ensure the desired amount is filled every time. This will reduce wastage and keep your workflow running smoothly.

Cost

Carefully consider the cost of operation as this will have an effect on the overall profitability of your product. Consider energy sources such as electricity or compressed air when making your purchase decision.

Ease of Use

Choose a small powder filling machine that is user-friendly, easy to operate and maintain, and requires minimal training for operators. Look for automated functions that can save time and simplify operations.

After-Sales Service

It is also important to check whether the supplier offers ongoing maintenance support and spare parts. This will ensure that the machine remains in good working order and any issues can be quickly resolved with minimal disruption to production.

CONCLUSION

Small powder filling machines offer versatile and efficient solutions for many industries. They are reliable and accurate, helping manufacturers save time and money. Companies of any size can benefit from increased accuracy and efficiency that these advanced machines provide. Furthermore, when used properly, these machines help to ensure product quality and consistency throughout the entire production process. Whether you're looking to fill a bulk amount or precision application of powder materials, these machines are the perfect solution. For more information on a small powder filling machines contact Allpack today.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide