Carton Taping Machine: The Complete FAQ Guide in 2025

Are you looking for a reliable and efficient way to package your product for shipping? Then maybe the carton taping machine is exactly what you need!

It’s the perfect solution for all your packaging needs, as it helps save time, money and effort. With so many advantages, there’s no doubt why this machine is one of the most sought-after equipment in warehouses and fulfillment centers around the world today.

Read on to find out more about how this easy-to-use taping machine works, its features, and benefits –and start getting ready to love how much easier your product packaging process can be!

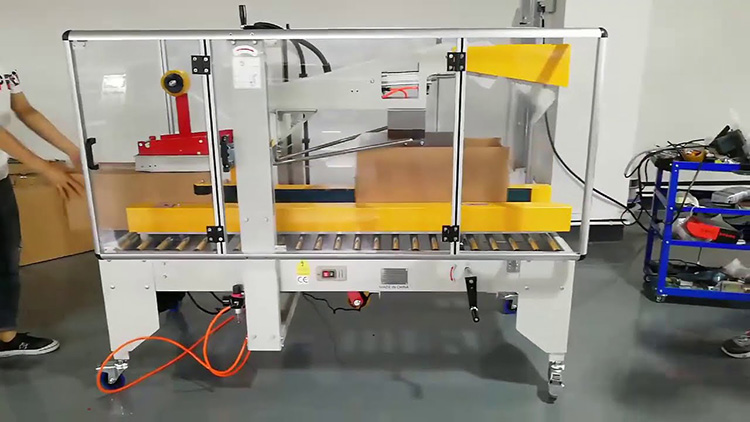

1.What Is A Carton Taping Machine?

A carton taping machine is a device used to securely seal cartons or boxes. It typically works by using adhesive tape, but can also work with foam and polypropylene strips.

These machines reduce labor costs and human error by quickly sealing cartons with an even, consistent amount of tape, ensuring the contents of the box remain safe in transit. Carton taping machines can be used in a variety of industries including ecommerce, pharmaceuticals, and food and beverage.

They are designed to work with cartons or boxes of all shapes and sizes, and some models even offer the ability to change tape widths with a touch of a button. By utilizing carton taping machines, businesses can save time and resources while providing secure carton protection.

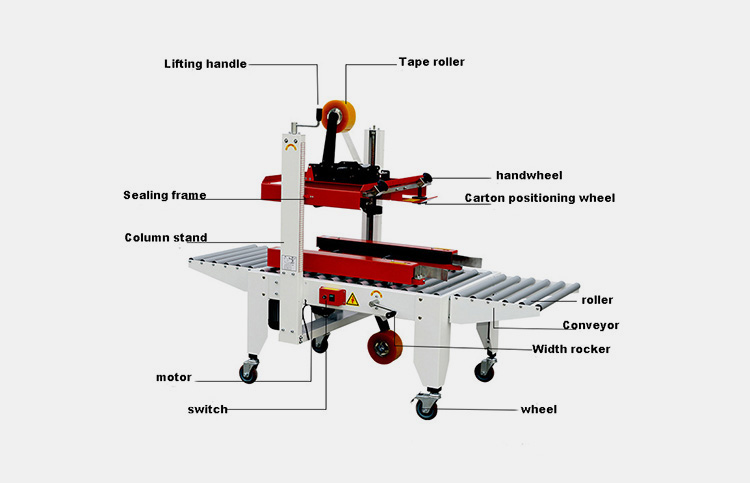

2.What Are The Components Of A Carton Taping Machine?

Switch– A switch is used to turn the carton taping machine on and off. This allows the operator to control when to begin and end the carton taping process.

Motor– The motor is the main component of carton taping machines. It is responsible for providing the power to move all of the other components.

Wheel– The carton taping machine is equipped with a wheel that helps it move around the workspace. This helps to make sure that the carton taping process is done efficiently and with accuracy.

Width rocker– The width rocker is used to adjust the width of cartons so that they can be taped accurately. This ensures that cartons of various sizes can be taped without any issues.

Conveyor– The carton taping machine is equipped with a conveyor belt that helps move cartons through the carton taping process. This ensures that cartons of various sizes can be moved quickly and efficiently

Roller– The carton taping machine is equipped with a roller that helps to apply the tape to cartons. The roller ensures that each carton is taped securely and accurately.

Carton positioning wheel– The carton positioning wheel helps the carton taping machine to position cartons so that they can be taped accurately and securely. This ensures that cartons of all sizes are able to be taped properly.

Hand wheel– The carton taping machine is also equipped with a hand wheel that allows the operator to adjust the tension of the tape being applied. This helps to make sure that cartons are taped securely and accurate.

Tape roller– The carton taping machine is equipped with a tape roller that helps to apply the tape to cartons. This ensures that cartons are taped securely and accurately.

Lifting handle– The carton taping machine is equipped with a lifting handle is a lever that is used to lift the carton off of the carton taping machine and move it onto the conveyor belt.

Column stand– The carton taping machine is equipped with a column stand that helps to support the carton as it moves through the carton taping process. This ensures that cartons of all sizes can be taped securely and accurately.

3.How Does A Carton Taping Machine Work?

A carton taping machine is a device that helps to secure the carton with tape. The carton taping machine works by placing adhesive tape across the opening of the carton, creating an airtight seal. This not only secures the carton against tampering and dust but can also help prevent damage during shipping.

The carton taping machine operates using two main components: a carton sealing head and the carton itself. The carton sealing head is generally made up of two metal plates that clamp down onto the carton opening to hold it in place.

It has adjustable roller guides so that different tape widths can be used, and also contains a carton sealing motor that drives the tape rollers. The carton itself is placed on the carton sealing head and then secured with adhesive tape, which can be applied manually or automatically by the carton taping machine.

4.Where Do Carton Taping Machines Be Used?

Retail and e-commerce warehouses

Carton taping machines can be used to seal cartons for retail and e-commerce warehouse operations. This allows cartons to be quickly sealed, reducing labor costs and increasing efficiency.

Pharmaceutical companies

In pharmaceutical businesses, carton taping machines are used to seal cartons that contain pharmaceutical products. This allows cartons to be sealed quickly and securely, preventing any tampering or damage during shipment.

Manufacturing operations

Carton taping machines can also be used to secure cartons that contain manufactured goods. This ensures that the cartons remain secure throughout the shipping process and prevents any loss of product while in transit.

Packaging operations

Carton taping machines can be used in packaging operations to quickly and securely seal cartons. This allows cartons to remain secure while being shipped and reduces the risk of any loss or damage due to tampering.

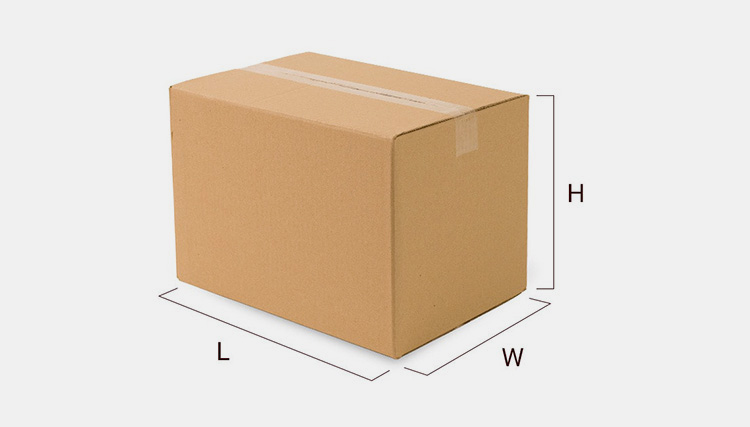

5.What Is The Maximum Carton Size That Can Be Handled By The Carton Taping Machine?

The maximum carton size that can be handled by a carton taping machine is determined by the carton size and bulk of the cartons being processed. Generally, carton taping machines are designed to handle cartons anywhere from 6″ x 4″ x 3″ up to 24” x 18” x 12”. carton taping machines may also be able to process cartons up to 36” x 24” x 18” depending upon the size and bulk of cartons being processed. It is important to note that carton sizes larger than these measurements may not be compatible with a carton taping machine, meaning they would require more specialized packaging equipment.

6.What Types Of Cartons Can Be Sealed With This Carton Taping Machine?

This carton taping machine can be used to seal a variety of cartons, including corrugated boxes, regular cardboard cartons, and even plastic cartons. This carton taping machine is capable of sealing cartons up to 20 inches wide and 12 inches tall.

With its adjustable speed control feature, the carton taping machine can be used to seal cartons of varying sizes and thicknesses. The carton taping machine is also capable of sealing cartons with a variety of tape types, including hot melt, water-activated tape, and pressure sensitive tape. This carton taping machine is perfect for companies looking to streamline their carton sealing process.

With the carton taping machine, cartons can be sealed quickly and securely, ensuring products are shipped safely and efficiently. With its powerful motor and durable construction, this carton taping machine is sure to provide reliable carton sealing for years to come.

7.What Types Of Carton Taping Machines Are Available?

Carton taping machines are used to seal cartons for shipping and storage. There are three main types of cartons taping machines: automatic, semi-automatic, and manual.

Automatic Carton Taping Machines.

Automatic carton taping machines use a motorized conveyor belt to transport the cartons through the machine and automatically close and tape them shut.

Semi-Automatic Carton Taping Machines

Semi-automatic carton taping machines are used to transport cartons through the machine, but they require manual closure and sealing of the cartons.

Manual Carton Taping Machines

Manual carton taping machines require a person to position the carton and manually close and tape it shut.

All three types of carton taping machines typically use pressure-sensitive adhesive tape for the sealing process. Depending on the carton size, carton taping machines can be configured to operate at speeds ranging from a few cartons per minute up to hundreds of cartons per minute.

8.Is The Carton Taping Machine Adjustable To Different Carton Sizes?

The answer is yes. Most carton taping machines are designed to be adjustable, allowing you to customize the machine to fit different carton sizes.

Adjustable carton taping machines feature adjustable height and width settings that can be easily adjusted using a simple manual adjustment lever or digital control system. This allows for quick and easy setup for different carton sizes and shapes

9.Is It Possible To Adjust The Carton Taping Machine’s Sealing Speed?

It is possible to adjust the carton taping machine’s sealing speed. Most carton taping machines have a variable speed control that allows you to adjust the sealing speed to match your production needs. The speed can be adjusted based on tape type, carton size, and application surface.

To make changes to the carton taping machine’s sealing speed, the operator must first identify the correct setting for the desired carton size and application surface. Once this is determined, they can adjust the speed accordingly based on their production needs.

It is important to note that carton taping machines with a higher sealing speed may require more frequent maintenance in order to maintain optimal performance. Additionally, carton taping machines with a lower sealing speed will require more time and effort to complete the packaging job. However, adjusting the carton taping machine’s sealing speed can ultimately provide flexibility and optimize production speeds for any carton size or application surface.

10.Does The Carton Taping Machine Come With An Integrated Carton Conveyor System?

The answer to this question depends on the carton taping machine model you are using. Most carton taping machines come with an integrated carton conveyor system, though some models may require a separate carton conveyor system for efficient operation. It is best to consult with the manufacturer of your carton taping machine to determine if an integrated carton conveyor system is included with your purchase.

If the carton taping machine, you are using does not come with an integrated carton conveyor system, there are still options available to you. The carton taping machine can be connected to a stand-alone carton conveyor system or a modular carton conveyor system, which can be customized to meet your specific carton taping needs.

No matter what carton taping machine you use, it is important to ensure that the carton conveyor system is properly installed for optimal results. The carton conveyor system should be compatible with the carton taping machine and should provide a smooth flow of cartons, as any delays or jams in the carton conveyor system can cause issues with your carton taping machine.

Choosing the right carton conveyor system for your carton taping machine is essential to getting the most out of your carton taping operation.

11.What Type Of Tape Can Be Used On The Carton Taping Machine?

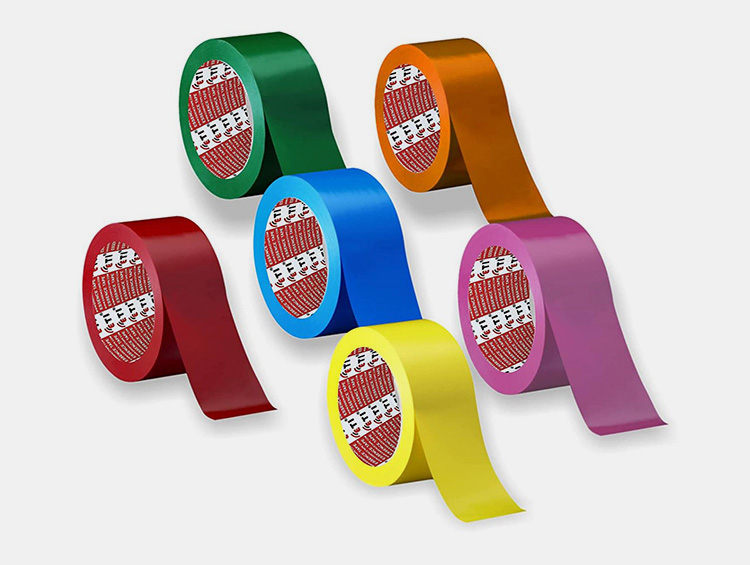

The type of tape that can be used on carton taping machines include:

Acrylic Tape

This type of tape is designed for carton sealing applications as it has a strong adhesive that ensures the carton will remain well sealed.

Acrylic tapes are known for their water and UV resistance, making them ideal for carton sealing applications.

Gummed Tape

Gummed tapes are designed to create an airtight and waterproof seal on cartons when the tape is activated by water. They are also strong and durable, making them a reliable choice for carton taping machines.

Hot Melts

Hot melts are thermoplastic adhesives that are melted and applied as carton tape. They are known for their strong adhesiveness and durability, making them a great option for carton sealing applications.

Pvc Tape

PVC tapes are designed to be used in carton taping machines and provide an excellent seal on cartons. The tape is highly stretchable, allowing it to conform to carton surface irregularities and keep the carton tightly sealed.

12.Is It Possible To Customize Carton Taping Patterns With This Carton Taping Machine?

Yes, it is possible to customize carton taping patterns with this carton taping machine. The carton taping machine comes with a wide range of features that allow users to select different carton taping patterns as well as adjust the tape tension and width according to their requirements.

It also offers an easy-to-use control panel that allows users to customize the carton taping pattern they need in just a few clicks. Moreover, the carton taping machine also comes with advanced safety features that make sure that cartons are securely taped and remain safe during transport.

All these features make it possible for businesses to customize their carton taping patterns according to their requirements. So, if you need to customize carton taping patterns for your business, this carton taping machine is definitely worth considering.

13.Does The Carton Taping Machine Come With A User-Friendly Interface?

Yes, carton taping machines come with a user-friendly interface. Many carton taping machines are equipped with intuitive controls that make it easy to use. You can usually find the necessary instructions on the machine itself or in its accompanying manual – so you don’t need to be an expert to operate one of these devices.

Modern carton taping machines come with digital displays, making it easier to select the appropriate parameters for a given job. The machine also adapts to different carton sizes and shapes. Depending on the model, some carton taping machines can even do multiple functions such as sealing, wrapping and packing at once. This is why carton taping machines are so popular in the packaging industry.

In addition to being user-friendly, carton taping machines can also be extremely efficient. Many modern carton taping machines offer fast speeds and high precision when it comes to completing a job. This means that you can get more work done faster and with fewer errors. Plus, carton taping machines are built to last, so you can count on them delivering reliable performance for many years.

14.Does The Carton Taping Machine Require Any Special Maintenance Or Repair?

It is important to regularly maintain and repair carton taping machines in order to ensure that they are functioning properly. In general, carton taping machines should be serviced on a monthly basis by trained technicians.

This includes checking for worn out parts, cleaning the machine, and making sure that all moving parts are lubricated. It is also important to regularly inspect the carton taping machine for any signs of damage or wear, and to make repairs as soon as possible.

If left unchecked, these issues can lead to decreased efficiency and increased downtime. In some cases, it may be necessary to completely replace certain parts of the carton taping machine in order to ensure that it functions properly. Furthermore, carton taping machines need to be routinely calibrated in order to ensure that the cartons are sealed properly and securely. Ultimately, with proper maintenance, a carton taping machine can provide reliable performance over an extended period of time.

15.How Reliable Is The Carton Taping Machine In Terms Of Sealing Cartons Accurately?

Carton taping machines are used to quickly and securely seal cartons, packages, and other materials. The reliability of carton taping machines depends on the quality of the machine as well as the operator. When selecting a carton taping machine, it is important to choose one that has a good reputation for accuracy and durability. It is also essential to choose a carton taping machine that is easy to use and maintain.

When operated correctly, carton taping machines can be very accurate. The cartons are often sealed using different types of tape such as plastics or papers, which provide an airtight seal and prevent contents from spilling out. Most carton taping machines also have a counter that measures the length of tape used, allowing carton operators to keep track of how much tape is used in each carton.

Carton taping machines also come with adjustable settings that allow carton operators to customize their cartons for different needs. The machine can be programmed to adjust the tension of the tape, size of carton, and speed of carton closure. This allows cartons to be sealed in a variety of sizes quickly and securely.

In terms of reliability, carton taping machines are quite reliable provided that the machine is being used correctly and maintenance is being done regularly on the machine.

16.What Are The Benefits Of Using A Carton Taping Machine?

Increased Efficiency: Carton taping machines are designed to be incredibly efficient, allowing for faster and more uniform carton sealing than manual methods. This increases the speed of production processes, reducing bottlenecks and improving overall productivity in the warehouse or factory.

Cost Saving: These machines can save on labor costs by eliminating the need for manual labor, as well as on carton sealant costs due to their more efficient use.

Improved Quality: By consistently applying carton seals with a carton taping machine, products are better protected from dust, moisture, and other external elements during shipping or storage. This helps to ensure that customers will receive high-quality items and that cartons will remain intact during transport.

Enhanced Safety: Manually taping cartons can be dangerous, particularly for workers with existing back or joint pain issues due to the need to repeatedly stoop and stretch. A carton taping machine eliminates this risk by doing the work for them. In addition, these machines reduce the risk of potential accidents due to lose carton seals.

In short, carton taping machines provide increased efficiency, cost savings, improved product quality, and enhanced safety benefits compared to manual carton sealing methods. As such, it makes sense for businesses who ship cartons regularly to consider investing in one of these machines.

17.Does The Carton Taping Machine Come With Any Safety Features?

Yes, carton taping machines typically come with certain safety features designed to protect the operator. Common safety features on carton taping machines include: reverse-stop sensors that stop the machine if it senses an obstruction; emergency stops and foot switches to quickly shut off the machine in case of an accident; guards around moving parts that help prevent contact with the machine; and air-pressure limit switches that shut off the machine if it starts to operate too quickly.

Other carton taping machines may also include safety features such as a photoelectric eye for tracking cartons, or an alarm system that alerts operators to any potential malfunctions. All carton taping machines should be used in accordance with the manufacturer’s safety instructions to ensure maximum protection.

Conclusion

A carton taping machine is an important tool to efficiently and securely package products, ensuring they reach their destination safely. With the right type of machine, it can even save time in packaging and shipping too! Allpack carton packing solutions have the best selection for businesses who want an efficient process. We offer quality machines with exceptional features that offer long-term value. Plus, our knowledgeable customer service team is ready to provide advice on any questions or concerns you may have about the machine or installation. Investing in your own carton taping machine today can make a positive difference for your business tomorrow – shop Allpack now for the best value and customer care!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours