Blister Packing Machine For Spices: The Complete Buying Guide In 2025

Are you in the market for a machine to help automate your spice packaging process? With the right equipment, you can ensure that each packet of spices is filled with precision and sealed properly every time. Fortunately, there are blister packing machines specifically designed to package spices efficiently and accurately.

In this blog post, we will discuss what a blister packing machine is, how it works to improve your spice packaging operations, and why it’s an essential tool for any business looking to streamline their production processes.

1.What Is A Blister Packing Machine For Spices?

A blister packing machine for spices is a specialized packaging machine specially designed to package and protect food items such as spices. The blister packing machine is equipped with advanced features that can seal individual portions of spices into blister packs without damaging them.

2.What Are The Components Of A Blister Packing Machine For Spices?

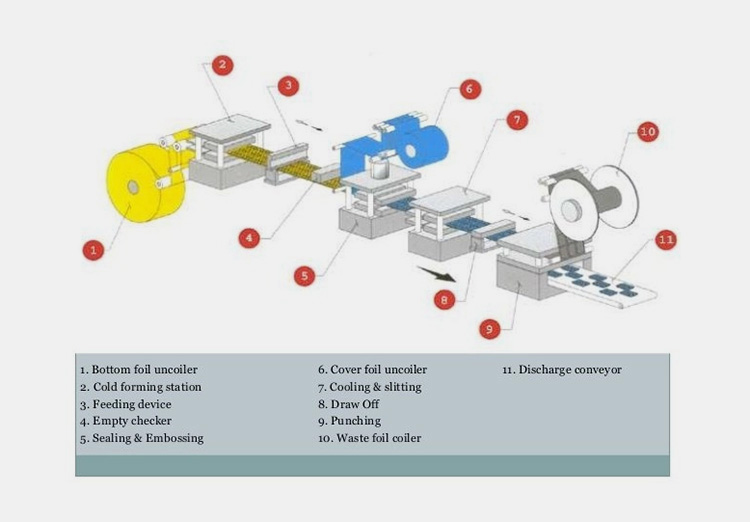

Parts of a Blister packing Machine

The components of a blister packing machine for spices include:

Bottom Foil Uncoiler

The bottom foil uncoiler is the component that supplies the bottom foil to the other machine components. It supports, tensions and feeds the foil onto the blister forming process.

Cold Forming Station

This station is where the blister pockets are made. Blister pockets are formed when a plastic film is heated and then pressed against a mold containing the products to be packaged.

Feeding Device

The feeding device is the component that puts the spices into the formed pockets. It can be manual or automatic, depending on the size and complexity of the machine.

Empty Checker

The empty checker is responsible for determining if the pockets are correctly filled with spices. It may use sensors to detect whether a pocket is full or empty.

Sealing and Embossing Station

This station seals the pockets with a top foil and embosses a logo or branding onto them. It also trims any excess material from around the edges of the pockets.

Cover Foil Uncoiler

This component supplies the top foil for sealing and embossing. It provides tension and feeds the foil into the sealing process.

Cooling and Slitting Station

This station cools the sealed pockets and slits them into individual packages.

Draw Off Device

The draw off device is responsible for transferring the completed pockets from the blister packing machine for spices to other machines or packaging lines.

Punching Device

This device punches cutouts in the top foil which can be used for product identification and security seals.

Waste Foil Coiler

The waste foil coiler is the component responsible for collecting and storing any excess material produced during the blister packing process. This may include scraps of top or bottom foil.

Discharge Conveyor

The discharge conveyor is used to transport the complete packets from the machine. It can be used for further packaging processes or for storage.

The blister packing machine for spices consists of these eleven components, which work together to form and seal pockets containing spices into individual packages. These packages are then ready for distribution and sale.

3.How Does A Blister Packing Machine For Spices Work?

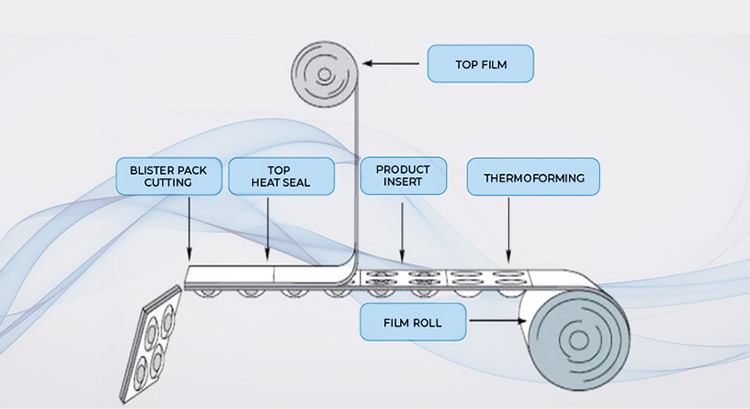

Blister packing process

This special type of machine is used to package small items such as spices. The Blister packing machine for spices uses thermoforming technology to vacuum form and cut the desired shape from a roll of plastic film. The formed product is then filled with the spice and sealed before being placed into an outer packaging material.

Blister packing machines for spices can be used to package a variety of items, including hardware, medical equipment, spices, herbs and other food products. The Blister packing machine for spices follows the same basic procedure for each product:

Process 1. Cutting

The Blister packing machine for spices uses a die and punch to cut out the desired shape from the plastic film. Depending on the size and shape of the product, different dies and punches can be used to achieve the desired result.

Process 2. Forming

The Blister packing machine for spices uses a vacuum chamber to form the plastic film onto a mold. This is done by using suction pressure to draw the heated plastic film into the shape of the mold. Depending on the size and shape of the product, different molds can be used.

Process 3. Filling

After the Blister packing machine for spices has formed the desired shape from the plastic film, it then uses an automated filling system to fill the Blister pack with the desired spice or food product.

Process 4. Sealing

Finally, the Blister packing machine for spices seals the Blister pack by heating and pressing the edges of the Blister pack together. This seals the Blister pack, preventing contamination and preserving freshness.

4.How Does A Manual Blister Packaging Machine For Spices Compare To Fully Automatic Blister Packaging Machine For Spices?

Manual Blister packing Machine For Spices

Automatic blister packing machine for spices

Manual blister packing machines for spices and fully automatic blister packing machines for spices differ when it comes to operation, cost, efficiency and complexity.

Operation

Manual blister packing machines for spices require manual labor to operate while a fully automated blister packing machine can be operated with minimal or no human intervention.

Cost:

Manual blister packing machines are usually more affordable than fully automated blister packing machines for spices, as manual blister packing machines for spices do not require complex technology or additional components.

Efficiency

Fully automated blister packing machines for spices can be more efficient in terms of time and materials used, due to their ability to complete processes quickly and accurately. However, manual blister packing machines for spices can also be used to achieve a certain level of accuracy and efficiency, depending on the operator.

Complexity

Fully automated blister packing machines for spices are typically more complex than manual blister packing machines for spices, due to the additional components used in their operation. These components require more maintenance and repair, making them more expensive over the long-term.

Overall, the blister packing machine for spices depend on a variety of factors and needs to be carefully evaluated before making a purchasing decision. While manual blister packing machines for spices may be more economical in the short-term, fully automated blister packing machines for spices may offer greater efficiency and accuracy over time. Ultimately, it is up to you as an individual to decide which blister packing machine for spices best suits your needs.

5.What Are The Applications Of A Blister Packing Machine For Spices.

Food Industry

This blister packing machine for spices can be used to pack a variety of spices, including ground pepper, cinnamon powder, turmeric, cumin seeds and many other types of herbs and spices.

Pharmaceuticals

The blister packing machine for spices is ideal for packaging tablets and capsules. It ensures the contents stay safe from moisture and dust until they reach the consumer. It also prevents tampering and reduces pilferage.

Cosmetics

Blister packing machines for spices can be used to package cosmetics, such as lipsticks and eyeliners, for retail sale. By blister packing these products, consumers can easily see what is inside the packages and make an informed decision before making a purchase.

Stationery Items

Blister packs are also widely used to package stationery items, such as erasers and correction pens, which require protection from outside elements. blister packing machines help ensure that these products reach the consumers in an unscathed condition.

Electronic Components

blister packing machines for spices are often used to package fragile electronic components like sockets, switches and connectors. This helps protect them from dust and other external elements until they reach their destination.

In conclusion, blister packing machines for spices are an essential part of the packaging industry. They are used to pack a wide range of items, including food, pharmaceuticals, cosmetics, stationery items and electronic components. By blister packing these products, manufacturers can ensure the safety of their contents and make them more appealing to consumers.

6.What Kind Of Materials Can Be Used With A Blister Packing Machine For Spices?

A blister packing machine for spices can be used with a variety of materials to package the product. These materials include

Aluminum Foil – Aluminum foil is often used as a blister pack backing material. It provides excellent protection against oxygen and moisture, as well as blocking out light.

Thermoformed Plastic – This is a common blister pack material that is heated and formed around the product to create a secure seal. It provides an excellent barrier to oxygen, moisture, dust, and other contaminants.

PVC – Polyvinyl Chloride is a common blister pack material that provides excellent protection against dust and other contaminants, while also providing an attractive appearance to the blister pack.

7.How Can Blister Packing Machines For Spices Be Used To Reduce Waste And Optimize Packaging Materials For Spices?

The blister packing machines for spices are a great way to reduce excess packaging waste and optimize the use of materials when packaging spices.

Blister packing machines for spices are designed to create airtight blister packs that keep moisture, heat, and light away while allowing some oxygen in. This helps protect the spices from spoiling too quickly, and also reduces the amount of packaging material needed.

By the use of blister packing machines for spices the packs that are airtight sealed reduce the risk of contamination and the materials used in the process can be more efficiently used.

Blister packing machines for spices are also able to produce packs that fit the exact size and shape of the spice container. This eliminates any unnecessary usage of packaging material and can help further reduce manufacturing costs.

When it comes to reducing waste and optimizing packaging materials for spices, blister packing machines for spices are the effective solution. With blister packing machines for spices, you can ensure that your spice products remain fresh and protected while minimizing the use of materials.

8.What Type Of Products Can Be Packed By A Blister Packing Machine For Spices?

A Blister Packing Machine for Spices can be used to pack a variety of products. These include:

Whole Spices – Blister packs are ideal for packaging whole spices such as pepper, cumin, cinnamon, cloves, and nutmeg. The blister packing machine seals the package in an airtight environment to preserve the freshness and flavor of the spices.

Ground Spices – Blister packs are ideal for packaging ground spices such as turmeric, coriander, ginger, paprika, and chili powder. Blister packing machines can ensure that the package remains airtight which helps to maintain the shelf life and taste of these powdered products.

Blends – Blister packs are also ideal for packaging spice blends such as garam masala, Italian seasoning, and French herbs de Provence. Blister packing machines can create uniform packages that will help to enhance the presentation of these products.

Seasonings – Blister packs are great for packaging seasonings such as sea salt, garlic powder, onion powder, and MSG. Blister packing machines can create airtight packages that will help to preserve the flavor and shelf life of these product.

9.How Can You Maximize The Performance Of A Blister Packing Machine For Spices?

Blister packing machine for spices

The blister packing machine for spices is an efficient and cost-effective way to package a variety of products. To ensure that the blister packing machine runs smoothly, it is important to follow best practices for maintaining and operating the machine.

First, it is essential to regularly clean and lubricate the blister packing machine for spices’ components in order to keep them in optimal working condition. Regular maintenance and cleaning can help reduce wear and tear on the machine, which can lead to improved performance over time.

In addition, it is important to check for any signs of damage or malfunctioning parts in order to avoid any costly repairs or downtime.

Second, it is also important to ensure that the blister packing machine for spices is properly set up. This includes ensuring that the blister packing material is loaded correctly and that there are no obstructions blocking the blister cavity.

Additionally, proper alignment of the components will ensure that all spices are sealed accurately for optimal performance.

Finally, it is important to run regular tests on the blister packing machine for spices after maintenance or setup is complete. This can help identify any issues or potential problems before they become serious and costly.

Additionally, these tests can be used to ensure that the blister packing machine for spices is operating at its highest capacity.

10.How Can A Blister Packing Machines For Spices Be Adapted To Fit Specific Spice Packaging Needs?

Blister packing machines for spices are highly versatile and can be adapted to a wide range of specific needs. Many blister packing machines come with adjustable blister pockets, making it easy to package different sizes or amounts of spice products.

Additionally, blister packaging machines can also be customized with additional features such as temperature controls, automated sealing systems, and other options to better suit the packaging needs.

These blister packing machines for spices also offer a variety of design options to meet spice companies’ specific requirements. Furthermore, blister packing machines for spices are also capable of packing multiple blister pockets at once, making them ideal for packaging larger volumes of spices quickly and efficiently.

In summary, blister packing machines for spices are highly versatile and can be easily adapted to fit a wide range of spice packaging needs.

11.How Can You Select A Blister Packing Machine For Spices?

Determine the blister size and shape you need

The blister packing machine for spices should be capable of creating blister packs in the specific shape and size required for your spices. It is important to get a blister packaging machine for spices that can handle both large as well as small blister sizes, depending on what type of spice you are packaging.

Choose a blister packaging material

Prior to selecting a blister packing machine for spices, you need to select the blister packaging material that is most suitable for your product. For spices, plastic or shrink wrap are two popular choices. Both materials provide excellent protection and ensure that the product remains fresh for longer periods of time.

Consider the blister sealing technology

Depending on your blister packing machine for spices, it may offer different blister sealing technologies. It is important to select the blister packing machine for spices that offers the highest quality blister seals in order to ensure that your spices remain uncontaminated and securely stored.

Choose a blister design

The blister design used should be able to both display and store the spices securely. It is important to select a blister design that will meet your product needs and ensure maximum efficiency in blister packing machines for spices.

Review additional features

Finally, review any additional features offered by blister packing machines for spices such as automated loading systems or rapid sealing capabilities. These features may prove beneficial in speeding up blister packing operations and improving overall efficiency.

CONCLUSION

A blister packing machine for spices is critical for packing spices. It can help to preserve the spices and prevent them from being damaged. Allpack provides high-quality blister packaging machines that are perfect for spices packaging. Contact Allpack today to learn more about a blister packing machine for spices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide