Stretch Wrapping Machine: The Complete Buying Guide In 2025

Do you want to take your business operations to the next level? Are you tired of dealing with wrapping and packaging products by hand? Then it’s time you invest in a stretch wrapping machine! Not only do they increase efficiency, but they can also help you cut costs.

In this blog post, we’ll examine exactly why a stretch wrapping machine is the perfect addition to your business operation. So if you’re ready to take things up a notch in your business, keep reading because we’ve got everything you need to know about a stretch wrapping machine. Let’s dive in!

1.What Is A Stretch Wrapping Machine?

A stretch wrapping machine is a specialized form of packaging equipment designed to stretch wrap stretchable film, such as plastic and paper around a variety of products. This device can be used for several applications such as bundling and palletizing boxes, as well as stretch wrapping containers.

The stretch wrapping machine utilizes tension in order to tightly secure the product or bundle with stretch wrap. This stretch wrap is then securely fastened to the pallet or product for storage and shipping purposes.

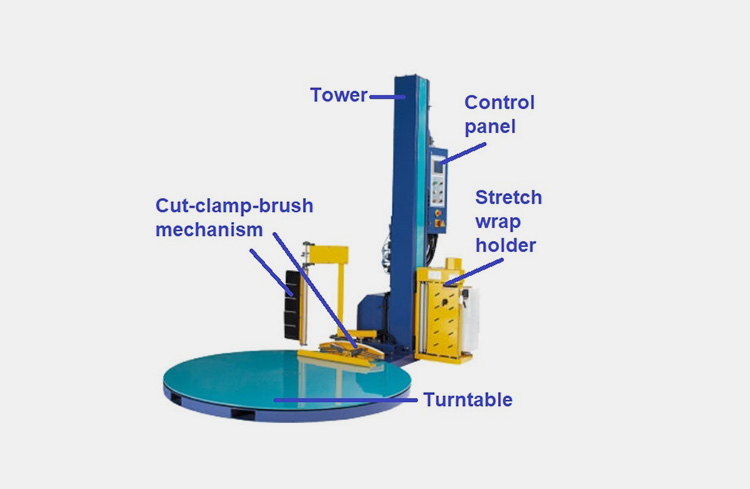

2.What Are The Components Of A Stretch Wrapping Machine?

Tower

This is the main frame of the stretch wrapping machine and it houses the core components including the turntable, stretch wrap holder and control panel among other components.

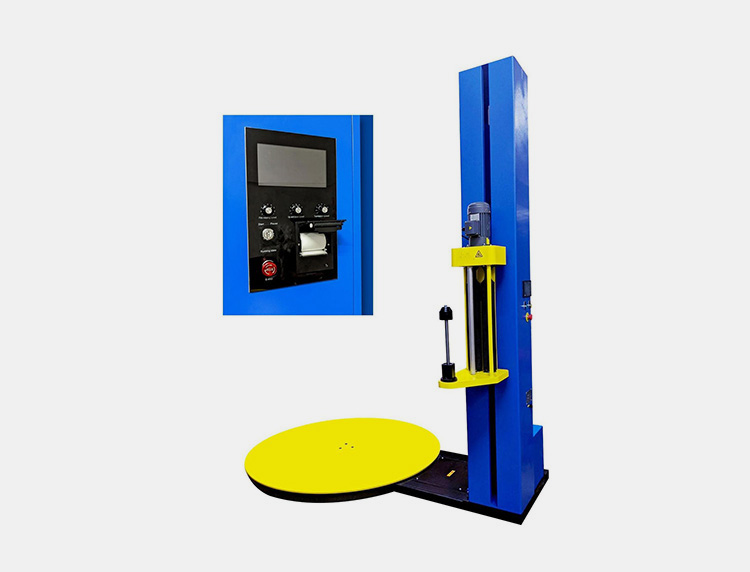

Control Panel

This component is responsible for controlling the stretch wrapping process as well as recording data and settings.

The control panel typically consists of a power switch, stretch wrap selector switch, stretch film tension selector knob, stretch wrapper speed control knob, and other buttons for controlling the stretch wrapping machine’s functions.

Stretch Wrap Holder

The stretch wrap holder is responsible for holding the stretch wrap material and winding it onto a reel. It commonly consists of a stretch wrap roll, core holder, and brakes that help regulate tension.

Cut-Clamp Brush Mechanism

This is a mechanism that clamps stretch wrap to the pallet and then cuts it off after wrapping has been completed.

Turntable

This component rotates the load when stretch wrapping; allowing the stretch wrap to evenly distribute and stretch around the load.

3.What Are The Merits Of A Stretch Wrapping Machine?

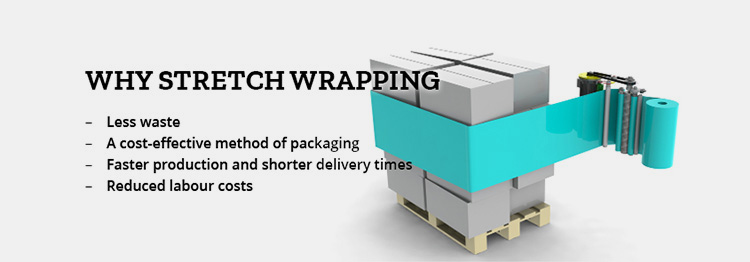

Improved Productivity: A stretch wrapping machine can dramatically increase productivity and reduce labor costs by automating the entire stretch wrapping process. This also helps to ensure that each pallet is wrapped consistently with minimum effort and time.

Cost Savings: By using a stretch wrapping you can save money on stretch wrap film since stretch wrapping machines can stretch the film up to three times its original length, meaning less stretch wrap is needed for each pallet.

Wrapping Quality: With stretch wrapping machines, companies can achieve a consistent and tight wrapping job that helps to protect the load during transit or storage. This also helps to reduce product damage and customer complaints due to mishandling or poor stretch wrapping.

Load Security: Stretch wrapping machines provide greater load security and stability of the pallet, which helps to minimize product loss or damage during transport or storage. This also reduces the risk of theft as it makes it more difficult for criminals to access the products being shipped.

Versatility: Stretch wrapping machines are designed to accommodate a wide range of different product sizes and weights due to their adjustable stretch wrapping tension and speed controls. This allows you to stretch wrap large or fragile loads without worrying about damaging the product.

4.What Are The Working Principles Of A Stretch Wrapping Machine?

The stretch wrapping process begins by feeding stretch film onto a stretch wrapper’s rotating ring. This stretch wrap is then wound around the product, moving up and down to ensure full coverage.

The stretch wrapping machine’s rotating ring moves in a pre-programmed pattern while winding the stretch film around the products. The stretch wrap is tensioned as it is applied to ensure a tight and secure stretch-wrap layer.

Once the stretch wrapping process is complete, a cutter blade severs the stretch film at the end of the rotation. The finished product is then removed from the stretch wrapper and ready for shipment.

5.Which Industries Can Benefit From Stretch Wrapping Machines?

Warehousing and Logistics

Stretch wrapping machines are integral to warehouse operations, as they securely wrap pallets of goods for transport. This ensures that during transit, goods remain safely secured in their packaging and arrive at the final destination without any damage or delays.

Manufacturing Industry

Many manufacturing companies use stretch wrapping machines to quickly and efficiently package their goods for transportation or storage. This helps reduce labor costs and improve the efficiency of packaging operations.

Food Service Industry

Stretch wrapping machines are used in the food service industry to package and store foods. This helps keep food fresh and free of bacteria, while also protecting it from environmental hazards such as moisture or dust.

Additionally, stretch wrap can prevent products from being tampered with during transit, providing an extra layer of security for valuable items.

Pharmaceutical Industry

Stretch wrapping machines are used in pharmaceutical companies to securely package sensitive goods, such as medical supplies or drugs. This ensures that the goods remain safe and secure throughout transit and beyond.

Retail Industry

Stretch wrapping machines are used in retail to secure products during shipment, as well as prevent theft. This helps protect valuable items, while also preventing them from being damaged due to shipping or handling.

Additionally, stretch wrap plays an important role in product presentation and merchandising, helping retailers attract customers and increase their sales.

6.What Are The Different Types Of Stretch Wrapping Machines Available On The Market?

a) Manual Stretch Wrapping Machines

Manual stretch wrapping machines are the most basic stretch wrappers and operate manually, meaning that they require an operator to manually wrap the stretch film around the product.

b) Fully Automatic Stretch Wrapping Machines

Fully automatic stretch wrapping machines are computer-controlled stretch wrapping systems that allow for a higher degree of automation. These stretch wrapping machines are typically used in large-scale industrial environments as they can wrap heavy loads quickly and accurately.

c) Semi-Automatic Stretch Wrapping Machines

Semi-Automatic stretch wrapping machines are manually operated, with the operator controlling the stretch wrap tension, speed and stretch wrap film unrolling. They are suitable for smaller loads and lower production rates but require more manual labor compared to other stretch wrapping machines.

d)Turntable Stretch Wrapping Machines

Turn table stretch wrapping machines feature a revolving turntable that allows the operator to stretch wrap a load without having to rotate it manually. They are usually automated and have adjustable speed settings, making them suitable for stretch wrapping a variety of different sizes and shapes.

e) Rotary Arm Stretch Wrapping Machines

Rotary arm stretch wrapping machines are designed for high volume applications. They use a stretch arm and electric motor to power the stretch film, as well as an automated system that can detect the size of packages and pallets, apply stretch film at pre-programmed tension levels, and continuously rotate around the package or pallet in order to wrap it multiple times.

f) Orbital Stretch Wrapping Machines

These machines are designed to stretch wrap cylindrical objects such as drums, barrels and other containers. They are typically automated and require limited operator involvement.

7.What Are The Differences Between A Stretch Wrapping Machine And A Shrink Wrapping Machine?

a) Stretch Wrapping Machine

b) Shrink Wrapping Machine

The main difference between stretch wrapping machines and shrink wrapping machines is the material they use. Stretch wrap is made out of stretchable plastic film that easily conforms to irregularly shaped items, while shrink wrap is a thicker plastic film which shrinks when heated.

The process for stretch wrapping usually involves applying stretch wrap around the product, either manually or with a stretch wrapping machine. Its stretchable nature makes it ideal to hold multiple items together and protect them from any physical damage during transport.

On the other hand, shrink wrap is applied by using heat to shrink the plastic film around the product, creating a tight seal which prevents tampering.

In terms of cost-effectiveness, a stretch wrapping machine is a more economical choice for large-scale operations compared to shrink wrapping machines. Stretch wrapping machines uses thinner film than shrink wrapping machines which reduces material costs, and stretch wrapping machines can typically process items at a faster rate as well.

However, in terms of protection, shrink wrapping machines provides superior coverage since it creates an airtight seal around the product which prevents moisture from entering.

8.What Are The Differences Between A Manual Stretch Wrapping Machine And An Automatic Stretch Wrapping Machine?

Manual Stretch Wrapping Machine

Automatic Stretch Wrapping Machine

Manual stretch wrapping machines are devices that require manual labor to secure a product with stretch film. They consist of a turntable, the manual operator and the material being wrapped.

Also, manual stretch wrapping machines are ideal for limited batch jobs or for those who don’t want to invest in an automated stretch wrapping machines. In addition, manual stretch wrapping machines are more affordable than the automated stretch wrapping machines, but manual labor is required to secure the load.

On the other hand, an automatic stretch wrapping machines are devices that use electrical motors and conveyor systems to automatically wrap products in stretch film. They are designed for large batch production jobs as they can produce more wraps per hour than manual devices.

Automatic stretch wrapping machines are usually more expensive than manual stretch wrapping machines, but they can save time and labor costs in the long run. Furthermore, automatic stretch wrapping machines generally offer greater safety and accuracy when wrapping products. Automatic stretch wrapping machines are also more efficient in terms of cost and production speed.

9.What Type Of Materials Can Be Used With A Stretch Wrapping Machine?

Polyethylene Stretch Film

This type of stretch film is the most common material used for stretch wrapping, due to its strength and ability to stretch up to 400%. It is strong enough to securely hold items together during transit and transportation, while being flexible enough to allow the stretch wrapping machine’s wrapping arm to move freely.

Polypropylene Stretch Film

This type of stretch film is ideal for lighter packaged items, as it offers a bit less stretch than polyethylene stretch film. It is able to hold items together while also providing a small amount of flexibility and movement.

Corrugated Boxes

These can provide an additional layer of protection for stretch wrapped items, and are also often used to simplify the stretch wrapping process by providing a sturdy platform for products to be securely attached to.

Paper

Paper can also be used with stretch wrapping machines, although it provides less stretch than stretch film and cardboard materials. It typically works well when packing books or other lightweight items that don’t require much stretch or protection.

Foam

Foam is a great material to use when stretch wrapping fragile items. The stretch wrapping machine can be used to wrap foam around the item and hold it in place, providing additional protection during transit and transportation.

Bubble Wrap

Bubble wrap can also be used with stretch wrapping machines to provide additional cushioning and protection for fragile items. The stretch wrapping arms are able to wrap the bubble wrap around the item and securely hold it in place.

Adhesive Tape

This material can be used alongside stretch film to help improve the stability and security of packages, as well as to provide an extra layer of protection against tampering.

10.What Type Of Products Can Be Wrapped Using A Stretch Wrapping Machine?

Palletized products

Stretch wrapping machines are frequently used for palletizing goods prior to shipment. The stretch wrap securely holds multiple items in place, allowing for easy transport and delivery with fewer damages

Bundled items

By using stretch film, bundles of items such as pipes, rods, bars and beams can be securely wrapped by stretch wrapping machines. This is a great way to protect multiple items from damage due to shifting during shipping or storage.

Unstable products

Stretch wrapping machines are also ideal for packaging irregularly shaped items that may not fit into conventional boxes. Axes, shovels, rakes and even furniture can be securely stretch wrapped with stretch film to ensure they are safe during shipping or storage.

Containers

Stretch wrapping machines can also be used to stretch wrap large drums, barrels and containers securely for transport. This is a great way to secure large containers and prevent them from leaking during transportation.

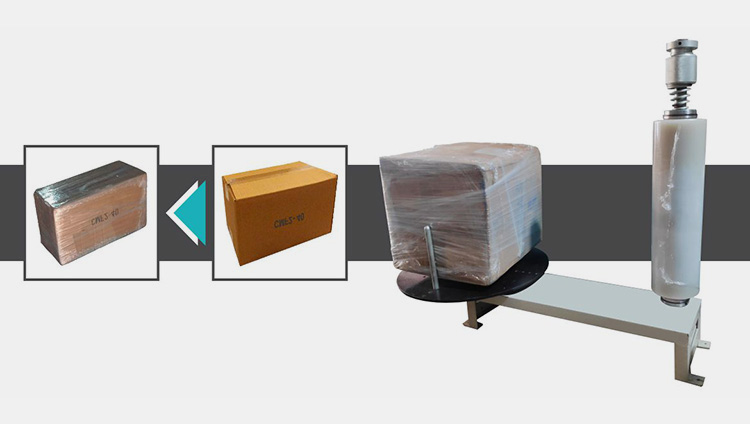

Boxes

Boxes of different sizes and shapes can also be stretch wrapped using a stretch wrapping machine to ensure the content is safe and secure during transit or storage. It’s a great way to protect boxes from damage, breakage or loss due to shifting during shipping or storage.

11.How Can Stretch Wrapping Machines Help To Improve Efficiency And Reduce Waste?

A stretch wrapping machine is a highly efficient and reliable way to securely bundle, package and transport products. This kind of machinery minimizes the time it takes to wrap pallets, protecting them from climatic changes and dirt which can occur during the transportation process. It also helps save money on packaging materials while reducing waste.

One of the main benefits of stretch wrapping machines is that they help improve efficiency in production and reduce waste. By automating the stretch wrapping process, it can significantly reduce the time spent manually wrapping pallets. This results in fewer employees needed for stretch wrapping tasks, thereby reducing labor costs and increasing productivity.

Additionally, stretch wrapping machines use stretch film which is a stretchable plastic material that can be wound around a pallet to keep items secure during transport. Stretch film is much lighter and thinner than other packaging materials, making it more cost-effective and reducing the amount of waste generated.

Furthermore, stretch wrapping machines help ensure that all the products on each pallet are tightly secured together. This reduces the risk of any items getting damaged in transit, thereby reducing the cost associated with repairs and replacements.

Also, stretch film is stretchable which allows it to conform to the shape of a pallet and keep all the goods tightly secured together. This ensures that each product will arrive safely at its destination without shifting or becoming damaged during transport.

12.What Are The Common Problems Associated With Stretch Wrapping Machines?

Film Breaking

Film Breaking – This is usually caused by a stretch wrapping machine not having the correct tension settings or having worn out tensioning components. It can also be caused by using an inferior stretch film that is too thin for the weight of the pallet being wrapped.

Over-stretching Film – If stretch wrapping machines are set too high it can stretch the stretch film past its breaking point, resulting in an ineffective stretch wrap.

Inadequate Wrapping – If a stretch wrapping machine is not set correctly or if worn out components are used; it can cause inadequate wrapping of the pallet. This could result in packages coming undone during shipping, or compromise the integrity of the stretch wrap.

Poor Distribution – If stretch wrapping machines are not set up correctly, it can result in poor stretch film distribution around a pallet which can cause weak spots when stretch wrapped.

Machine Malfunction – Age and wear and tear of stretch wrapping machines can lead to machine malfunctions that can cause stretch wrapping to not be effective. This could lead to stretch film being used inefficiently, or inadequate stretch wrap of a pallet.

Turntable not Turning-This can be as a result of no power supply, bad fuse, motor overload, loose belt or chain off sprocket.

Dirty Film – If a stretch wrapper is not maintained correctly it can result in dirt and debris getting trapped in the stretch film which reduces its effectiveness when applied to pallets.

Film Waste – If stretch wrapping machines are not set correctly or if inferior stretch film is being used, it can result in stretch film being wasted due to over stretching or inadequate stretch wrap.

13.How Can You Troubleshoot Common Issues With A Stretch Wrapping Machine?

Troubleshooting stretch wrap machines can be a daunting task, especially when they malfunction. To help simplify the process, here are some tips to troubleshoot common issues with stretch wrapping machines:

Check power connections – Inspect all electrical connections and make sure they are securely connected and properly grounded. Make sure the stretch wrapping machine is properly connected to a reliable power source.

Check stretch wrap tension – Make sure the stretch wrap is loaded correctly and that it is applied with the proper tension for effective stretch wrapping. If the stretch wrap does not stretch far enough before breaking, it may need more tension or higher-quality stretch wrap material.

Inspect stretch wrap roller – Make sure the stretch wrap rollers are clean, lubricated, and free of obstructions or debris that can interfere with stretch wrapping.

Check stretch wrap delivery system – Inspect the stretch wrap delivery system to make sure it is functioning properly and not blocking stretch wrapping material from entering the stretch wrapping machine.

14.How Can You Choose A Stretch Wrapping Machine For Your Business Needs?

When it comes to choosing a stretch wrapping machine for your business needs, there are several factors that you should consider.

First and foremost, you should consider the type of product that you need to stretch wrap. Different stretch wrapping machines are designed for different applications. For example, automated stretch wrapping machines are designed to quickly wrap large amounts of products at once, while manual stretch wrapping machines are better suited for smaller loads.

In addition to the type of product to be stretch wrapped, you should consider the size and weight of your product as well as the speed at which you need your stretch wrap job completed. Many stretch wrapping machines come with adjustable speeds to accommodate any job.

Furthermore, you should also consider the stretch wrap film you plan to use. Different stretch wrapping machines are designed for different stretch wrap films, so be sure to choose a stretch wrapping machine that is compatible with the stretch wrap film your business uses.

Finally, cost should also be taken into consideration when selecting a stretch wrapping machine. Manual stretch wrapping machines tend to be more economical than automated stretch wrapping machines, but they also require more labor. Automated stretch wrapping machines can help reduce labor costs, but they tend to be more expensive than manual stretch wrap machines.

Choosing the right stretch wrapping machine for your business needs doesn’t have to be a daunting task. By considering the type of product you need to stretch wrap, the size and weight of your product, the stretch wrap film you plan to use, and cost, you can easily select a stretch wrapping machine that is perfect for your business needs.

CONCLUSION

In conclusion, stretch wrapping machines can be a very effective way to package and secure products for shipping. With a wide range of options and sizes available on the market, Allpack can be the perfect solution for your needs. If you need help in selecting the right stretch wrapping machine for your business, contact Allpack. Our knowledgeable staff can answer any questions you might have about what type of machine is right for your business and how to use it correctly. Don’t hesitate – get in touch with us today and start using the power of stretch wrapping machines to increase your productivity and keep your goods safe!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide