Vertical Form Fill Seal Machine:The Complete Buying Guide in 2025

As technology advances ever more rapidly, a range of new innovations appear on the market daily. Nowhere is this truism more apparent than in the packaging industry, where automating processes has become a cornerstone of success. A great example is Vertical Form Fill Seal machines which have revolutionized how products are packaged and dispatched to customers worldwide. Their efficiency, speed and cost-effectiveness have made them an invaluable asset for production lines around the world; but before investing in one it’s important to understand exactly what they can offer your business process.

In this guide we aim to provide you with all the information needed so that by 2023 you can find yourself confidently purchasing and using a Vertical Form Fill Seal machine.

1.What Is A Vertical Form Fill Seal Machine?

A vertical form fill seal machine is a type of packaging machinery designed to create packages from flat rolls of material. It works by forming a pouch or bag, filling it with the desired product, and sealing it shut. The machine can be set up to package many different types of products such as powders, liquids, granular materials, and even solid items. The process is usually automated, which means it can be used to quickly and efficiently package large quantities of items for distribution.

With its ability to create custom packaging solutions, a vertical form fill seal machine is an essential piece of equipment for any business that needs to package products for sale. It’s also a great way to save time and money, as it eliminates the need for manual labor and can be set to run continuously.

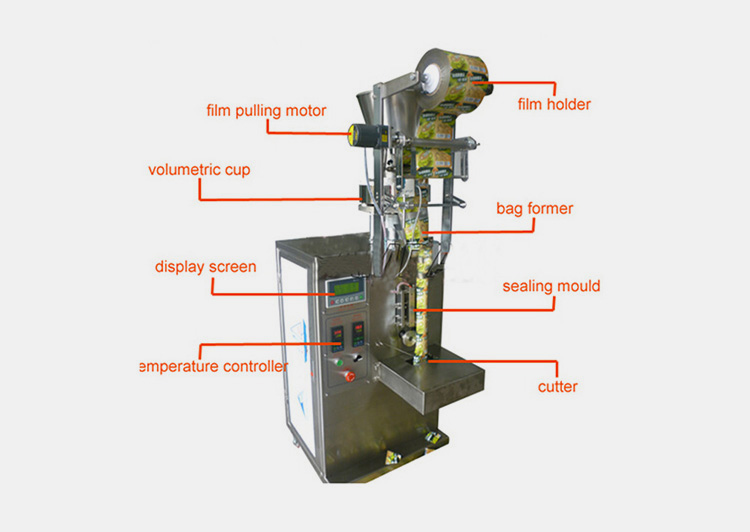

2.What Are The Different Components Of A Vertical Form Fill Seal Machine?

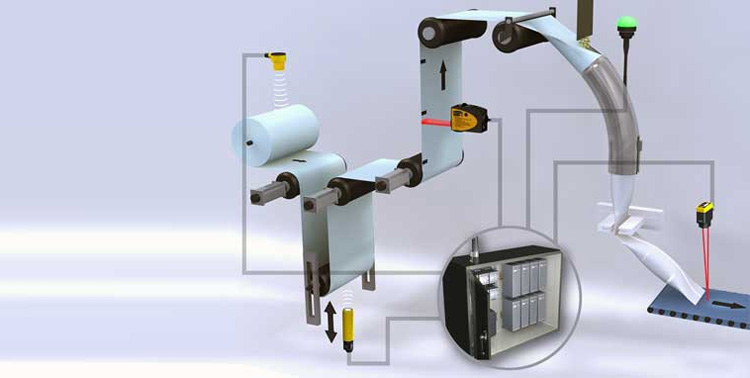

A Vertical Form Fill Seal Machine (VFFS) is a versatile packaging system that uses flexible film to form and seal bags from a single roll. It can accurately package products of different sizes and shapes, while automating the process with speed and accuracy. There are five main components of a VFFS machine: the unwind unit, the form fill seal area, the bag-making system, the filling unit and the exit conveyor.

Film Pulling System

The film pulling system is responsible for pulling film from a parent roll and feeding it into the form fill seal area of the machine. This component features an adjustable brake to prevent overrunning or underrunning, as well as a pneumatic clutch that ensures smooth and precise feeding.

Bag-Making System

The bag-making system is responsible for controlling the shape and size of the product bags generated by the machine. It includes a film tracking system, pressure rollers, cutting blades and other components that work together to form a variety of different bag shapes and sizes with precision.

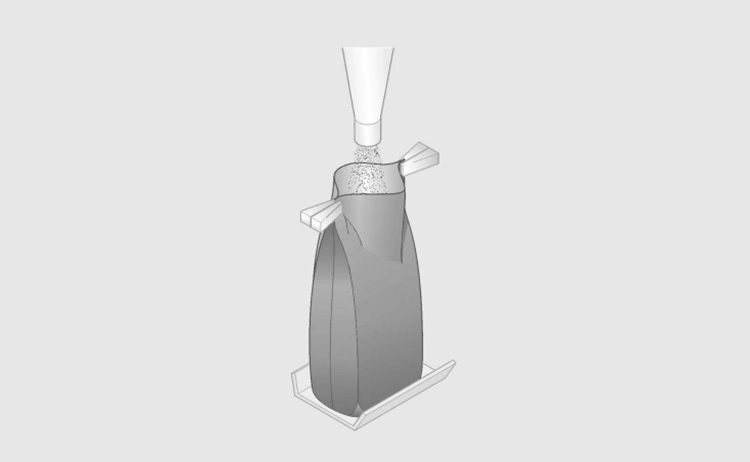

Filling Unit

The filling unit is where the product is loaded into the bags. Depending on the type of product being packaged, it can include auger fillers, volumetric cup fillers or other types of filling systems designed for specific products and applications.

Control panel

The control panel is used to adjust the settings of the machine and monitor any problems that may arise. It typically consists of a series of buttons, switches, gauges and displays that allow for easy adjustments and troubleshooting.

3.How Does A Vertical Form Fill Seal Machine Work?

A vertical form fill seal machine is an automated packaging system used to rapidly create packages. It works by taking a flat roll of material, such as plastic or paper, and forming it into a pouch or bag. The material then passes through the machine where the bottom is sealed, the product is filled and the top is sealed to complete the package.

The process begins by cutting a sheet of material from the roll and forming it into a pouch using two sets of clamps (the forming station). This is then sealed at the bottom either with heat or glue, depending on the type of packaging material.

Next, the product is loaded into the pouch at an automated filling station. The product is either loaded directly into the pouch by hand or via a conveyor system. Once filled, the top of the pouch is sealed and excess material is trimmed off (the sealing station).

Finally, the package passes through an inspection station where it is checked for errors such as incomplete seals and incorrect fill levels. If any issues are detected the package is rejected and sent back for correction. Once all packages have been verified, they are then ready for shipping.

4.What Applications Are Suited For A Vertical Form Fill Seal Machine?

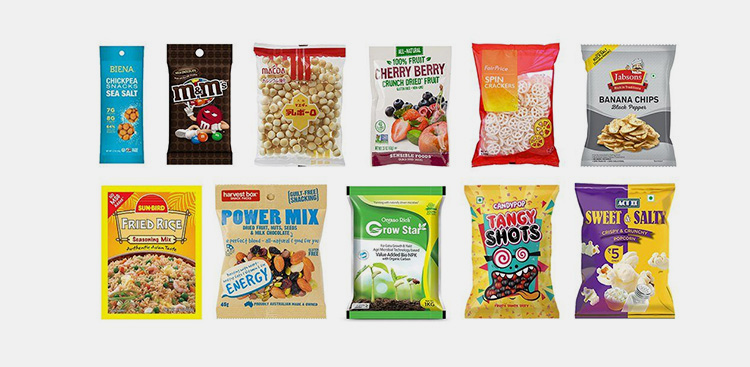

A Vertical Form Fill Seal Machine is widely used in the food industry for packaging dry goods like grains, nuts, cereals and other granular items. But this technology can be used in many other industries as well.

Food Industries

In the food industry, it can be used for packing a range of products such as snacks, confectionery, beverages and ready-to-eat meals in different sizes and shapes. It is capable of working with various materials like paper, foil, film or laminate to create hermetically sealed packets.

Pharmaceutical and Medical Industries

It can be used for packing medicines, vitamins and supplements in different containers like blister packs, sachets or bottles. This machine is suitable for drug filling applications as it can precisely adjust to the material type and thickness without wasting materials or products.

Chemical and Detergent Industries

This machine can be used for packing detergents, fertilizers, adhesives and other chemicals in a range of container sizes. The material that is used must be able to withstand the exposure to certain chemicals as well as temperature and pressure changes.

Cosmetics

The vertical form fill seal machine is perfect for the cosmetics industry as it can quickly produce a wide range of product packages with different shapes and sizes. The high-speed functioning of the machine allows for an efficient production line and ensures that the cosmetics reach their destination quickly.

Industrial

The vertical form fill seal machine is used in industrial applications as well. This includes applications such as packaging automotive parts, hardware components, and electrical components. Its high speeds allow for efficient production lines, while its customizability ensures that the packages meet the customer’s needs. Additionally, its precise sealing system guarantees secure and reliable packaging of the products.

5.What Are The Advantages Of Using A Vertical Form Fill Seal Machine?

Using a Vertical Form Fill Seal Machine (VFFS) comes with numerous advantages, including increased accuracy and efficiency. Here are some of the benefits of using a VFFS machine:

Cost Savings

A vertical form fill seal machine is highly efficient and cost effective compared to manual packaging processes. It eliminates the need for additional labor costs, as well as the time it takes to manually package products.

Increased Production Capacity

A vertical form fill seal machine can significantly increase production capacity due to its high speed and efficiency. It is capable of completing multiple packaging processes at once, resulting in a faster turnaround time for products.

Consistent Packaging Quality

A vertical form fill seal machine ensures that each product is packaged uniformly and efficiently. This means that the packaging process remains consistent from batch to batch and provides customers with uniform quality products every time.

Improved Product Safety

A vertical form fill seal machine provides improved product safety by ensuring that each package is tightly sealed and free of contamination or damage. This protects the product during shipping and handling, resulting in a better user experience.

Adaptability

A vertical form fill seal machine is highly adaptable and can be used to package different kinds of products, such as liquids or powders. This makes it an ideal choice for companies that need to package a wide range of products quickly and efficiently.

6.Are There Different Models Of Vertical Form Fill Seal Machines?

The Vertical Form Fill Seal (VFFS) process is a great way to automate packaging and increase your productivity. There are several models of VFFS machines available, each with their own advantages and features. Let’s take a look at the four main types:

Auger Filler Vertical Form Fill Seal Machine

These machines are the most widely used for packaging dry products such as granules, powders and other free-flowing materials. It uses an auger system to measure out a specific amount of product, which is then enclosed in a bag or pouch. The bags are then filled with the product and sealed shut.

Multi-Head Weigher Vertical Form Fill Seal Machine

This type of machine is ideal for packaging products that are too small or too varied in weight to be accurately and efficiently filled with an auger system. It uses multiple weight cells to measure out the exact amount of product needed, which is then enclosed in a bag or pouch and sealed shut.

Volumetric Cup Filler Vertical Form Fill Seal Machine

A volumetric cup filler VFFS is ideal for packaging products that need to be dispensed in a more controlled manner than with an auger system. It uses a series of volumetric cups to measure out the exact amount of product needed, which is then enclosed in a bag or pouch and sealed shut.

7.What Is The Difference Between Vertical Form Fill Seal Machine and Horizontal Form Fill Seal Machine?

The key difference between the vertical form fill seal machine and horizontal form fill seal machine is the orientation of their forming tubes. The former has a vertical orientation, while the latter has a horizontal orientation. Additionally, the vertical form fill seal machines are typically used for applications that require higher speeds, as well as having higher flexibility in terms of its packaging. On the other hand, the horizontal form fill seal machines are typically used for applications that require lower speed and more accuracy.

In terms of their construction, both types of machines use a combination of mechanical, electrical, and pneumatic components to create a complete packaging solution. With vertical form fill seal machines, the forming tube is set up vertically, and the entire product is released from the top of the machine. This design allows for multiple products to be packaged at the same time and increases the speed of production. On the other hand, horizontal form fill seal machines have a forming tube that is set up horizontally, with each product being released from either side of the machine. As such, each product has to be packaged separately, resulting in slower production speeds.

Furthermore, the vertical form fill seal machines are capable of packing more complex products due to their flexible nature and ease of changing settings on the machine. Conversely, horizontal form fill seal machines are designed for simpler packaging that requires less flexibility as it is unable to accommodate multiple sizes and shapes.

In short, vertical form fill seal machines are ideal for high-speed production with flexible packaging, while horizontal form fill seal machines are better suited for slower and more accurate production that requires simpler packaging. The choice of machine will mainly depend on the type of product being produced and the speed required in production. It is important to note that both types of machines are reliable and efficient when used correctly.

8.What Types Of Products Can Be Packaged With A Vertical Form Fill Seal Machine?

A vertical form fill seal machine is a versatile packaging solution that can be used for a variety of applications. The most common types of products packaged with these machines include:

Bakery items

From muffins and pastries to cookies, donuts, and other baked goods, vertical form fill seal machines are perfect for packaging bakery items. They can easily seal and package a variety of sizes and shapes, ensuring that your baked goods stay fresh and delicious.

Snacks

Snack foods such as chips, pretzels, crackers, popcorn and more can be packaged with a vertical form fill seal machine. These machines are able to handle higher volumes of product and can form airtight seals to ensure maximum freshness.

Milk-based products

Vertical form fill seal machines are also great for packaging milk-based products. With their precise sealing capabilities, you can ensure that your dairy-based beverages and cheeses stay fresh and safe to consume.

Produce

Fresh fruits and vegetables can be packaged with a vertical form fill seal machine. The machines are able to accommodate many different types of produce, including apples, oranges, carrots, potatoes, and more. This type of packaging is ideal for ensuring that your produce stays fresh and safe for consumption.

Dry goods

Dry foods such as cereal, flour, sugar, and other baking ingredients can be packaged with a vertical form fill seal machine. These machines are able to handle various large volumes of product. Additionally, they create hermetic seals that keep the food fresher for longer periods of time.

Lotions and creams

When it comes to the cosmetic industry, lotions, creams and other similar products can be packaged with a vertical form fill seal machine. This type of packaging ensures that your product is sealed securely and helps protect the integrity of the ingredients.

Syringes

Another product that can be packaged with a vertical form fill seal machine is syringes. The machines are able to create hermetic seals around the product, ensuring that it stays sterile and safe for use.

9.What Types Of Packaging Materials Work Best With A Vertical Form Fill Seal Machine?

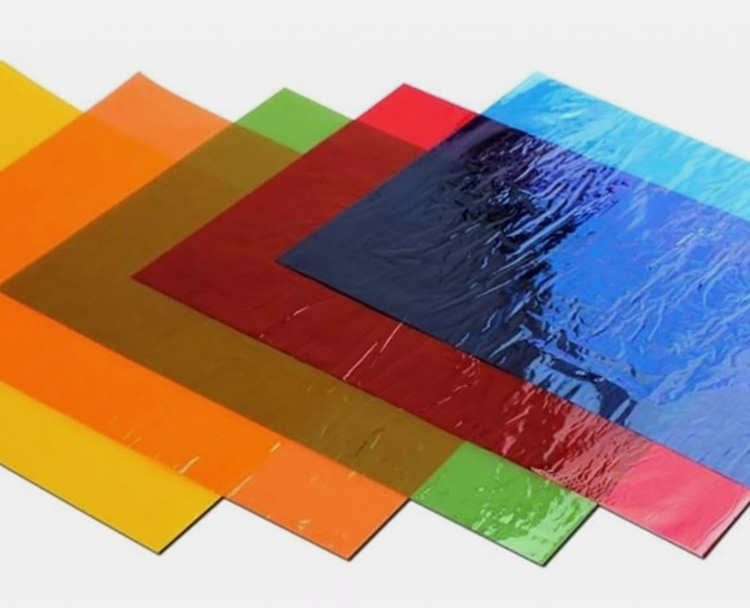

When considering packaging materials for a vertical form fill seal machine, it is important to consider the application requirements of your product. Different types of packaging materials can offer different levels of protection and sealing capabilities. Here are some of the most common types of packaging materials used with vertical form fill seal machines:

Polyethylene (PE)

Polyethylene is a flexible thermoplastic film made from ethylene gas. It is resistant to moisture and punctures, making it an ideal choice for packaging food products like snacks. Polyethylene is also cost-effective and easy to print on.

Polypropylene (PP)

Polypropylene is a stiffer plastic film than polyethylene that offers greater strength and barrier properties. It can be used for a variety of food applications such as baking mixes and dry foods. Polypropylene is also heat-sealable and has excellent barrier properties for moisture, oxygen, and aromas.

Cellophane

Cellophane has a glossy finish and is often used to create attractive packages. It offers excellent moisture protection, making it suitable for protecting products like food items that need to stay dry.

Aluminum Foil

Aluminum foil provides exceptional thermal and moisture protection, making it ideal for long-term storage or shipping of products like pharmaceuticals and food items.

Co-extrusions

Co-extrusions are two or three layers of different materials fused together to create a single film with unique physical properties. This type of film can be used in vertical form fill seal machines for applications like medical products or snacks. It is also tear resistant and can be printed with high-resolution images.

Lamination

Laminations are films that have been fused together to create a multi-layered structure. They can offer superior barrier properties and strength, which makes them ideal for packaging items like snack foods. Additionally, they are often printable, making them an attractive choice for branding.

10.How Do You Troubleshoot Common Issues With A Vertical Form Fill Seal Machine?

In order to fix common issues with a vertical form fill seal machine, it is important to first identify the problem. Is there an issue with the bag length or width? Does the pouch tracking keep shifting? Is the packaging material cutting or sticking together? These are all typical errors that can arise during operation.Once you have identified the issue, you can begin troubleshooting.

If the issue is related to bag length or width, it could be because of incorrect settings or a broken seal bar. To fix this problem, adjust settings and/or replace the seal bar as necessary. If pouch tracking keeps shifting, check for misalignment between the product feeder and the machine. If the packaging material is cutting or sticking together, ensure that the correct type of packing film is being used and check for any contamination.

Once you have identified the cause of the issue, it’s important to follow a step-by-step process to fix it. This can include checking machine speed settings, inspecting safety devices and sensors, and adjusting or replacing any worn or broken parts. Finally, ensure that all maintenance work is done correctly and regularly to prevent future problems. With the right troubleshooting skills and a bit of patience, you should be able to resolve common issues with a vertical form fill seal machine quickly and effectively.

Conclusion

A quality vertical form fill seal machine is an important investment for any business that wants to improve efficiency and product quality. We hope that this guide will help you understand the various types of machines available in the market and their key features. Allpack is one of the leading manufacturers and suppliers of packing machines in China. We have a team of experts who can advise you on the best machine according to your requirements. Contact us today for all your packing needs!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide