Juice Filling Machine: The Complete FAQ Guide In 2025

Whether its vegetables or fruits their daily intake is necessary for maintaining a healthy lifestyle. Research has also shown that extracted juices are healthier than that of consuming fruits or vegetables directly. However, most of the people are unable to prepare juices at home due to their busy routine.

Here the need for premade juices is realized that eventually led the manufactures to rethink about their existing production line and deliver fresh pulp juices to meet the global demand. On the other hand, it also raises the responsibility on part of manufacturers to provide these juices while keeping in view all the hygienic standards required for the process. The production line of preparing juices has covered many equipment under its umbrella, among which an essential instrument is juice filling machine.

Juice filling machine is carrying out the major task of filling exact amount of material into different containers, bottles and bags. It is effectively contributing in making the packaging of industries reach high standards. This is the reason why every firm is keen to bring this technology into use. If you are also interested in purchasing or knowing about a juice filling machine you should thoroughly examine this detailed FAQ Guide. Just take start and be among them!

1.What Is A Juice Filling Machine?

A juice filling machine is a device introduced to fill premade bottles with an accurate amount of juice without any waste. It works through a systematic process efficiently that eventually increases your production volume.

Many producers aim to use a juice filling machine because they want to deliver their juices in a hygienic and safe way. In addition to processing juice, this machine is also capable of processing milkshakes, cold drinks, wine, sauces, and many other liquids.

2.When To Use A Juice Filling Machine?

You might be wondering: When should I use a juice filling machine? Is it essential that your participation be a requirement before purchasing a juice filling machine? Precisely not! There is not a set guideline for purchasing a juice filling machine; all you need to know is understanding the nature of your production. For instance, if you work in the food processing sector and make a variety of sauces, such as currine, soy sauce, or chili sauce, you can definitely utilize a juice filling machine to improve the accuracy and efficiency of your packaging line.

3.What Do You Know About The Working Principles Of A Juice Filling Machine?

If you are interested in buying a juice filling machine, it is crucial to understand how it operates. Reading the following points will help you comprehend these operating principles:

Material Loading

You must first examine your machine for regular maintenance and ensure that all of its components are correctly installed and cleaned. After that, fill your holding tank with your stuff

Setting Parameters

Using the touch screen control panel, adjust the machine’s operating parameters. These variables include the pace, height, and amount of filling nozzles, among others

Bottle Filling

The actual filling of the bottles is the next stage. Through a conveyor belt, the bottles were transported to the filling station, where the equipment properly detected and filled the bottles to the desired level.

Bottle Discharging

Filled bottles are finally discharged onto a conveyor belt for capping, sealing, and labelling.

4.What Is The Role Of A Juice Filling Machine In Liquid Production?

If you process any kind of beverages, sauces, or other liquids, juice filling machines play a key part in your manufacturing line. It makes sure that each bottle is filled precisely, which ultimately cuts down on waste.

Due to its high level of automation, the machine runs efficiently with the least amount of operator interaction and error. Additionally, the machine’s corrosion-resistant design completely ensures that your content is secure and clean.

5.How Does A Juice Filling Machine Beneficial For You?

Using a juice filling machine has many advantages if you process juices or any other liquids, such as cold drinks, dairy goods, or wine. Below is a detailed discussion of these advantages:

Efficient

The level of production efficiency provided by a juice filling machine is one of its most notable advantages. This will eventually increase your output while cutting down on your workload.

Flexible

This machine not only fills the same quantity of material into the same kind of container, but it is also used to fill a variety of containers, such as plastic bottles, glass jars, and cardboard boxes. Additionally, the machine is able to handle variations in filling and material thickness.

User-Friendly

A heavy-duty industrial juice filling machine may appear to have a challenging operating mechanism. The situation is different, though, because the machine is relatively simple to operate and regulate thanks to the user-friendly control system.

Scalable

A juice filling machine has several advantages, but its scalability is one of the most important. It implies that if your production or workload increases, your equipment may simply be modified to handle it rather than needing to be replaced. For instance, you can upgrade your juice filling machine by adding more material tanks and filling tubes.

Increase Perfection

Every company strives to give their clients perfectly packaged items in order to establish a solid reputation and differentiate their brands from the competition. To meeting this goal, a juice filling machine completely assures appropriate filling.

6.Which Type Of Packaging Is Used By A Juice Filling Machine?

You have probably used a variety of juice containers, but have you ever given their construction any thought? Here is a brief explanation of each of the packages and containers that a juice filling machine uses:

Plastic Bottles

Due to the high degree of flexibility and durability, plastic bottles are still used to convey majority of the beverages, including juices, milkshakes, cold drinks, and water. Polyethylene terephthalate, the material used to make these plastic bottles, is incredibly versatile. It is entirely recyclable and only needs a low temperature to begin the breakdown process. Furthermore, plastic bottles are unlikely to break, thus their shapes are preserved.

Glass Bottles

Glass is a delicate object which is prepared from silica sand, soda ash and limestone. Being inert and non-toxic is its most important quality. For the purpose of maintaining original quality of the content, majority of industries favor packaging their beverages in glass bottles. Due to high level of non-reactive tear resistance, glass bottles are frequently used to package beverages like wine and juices.

Cans

A can is a type of metal container used to store range of goods, such as liquids, solids, and gases. The majority of juice cans are made of thin steel, aluminum, or tin with additional layers added to prevent corrosion. Cans are sturdy, which means they cannot be easily damaged, and recyclable, just like other packaging containers. The reason that cans encourage oral intake and eliminate the formality of putting canned juice into glasses, people prefer using cans.

Carton Boxes

Another popular type of packaging for keeping juices is carton boxes. They are constructed from packaging that has 3-6 layers of composite material, such as paper, aluminum, plastic, etc. Together, these components make up the juice box’s brick structure and offer the inside content exceptional defence against light, moisture, and pollution. Carton boxes are frequently used to package beverages like fruit juice, vegetable pulp, milkshakes, and lassis.

Plastic Pouches

Juice is packaged not only in bottles but also in plastic pouches. The most prevalent types of plastic pouches are stand-up pouches, doy packs, and handheld reusable spout pouches. Many producers are considering providing their fresh juices in attractive pouches due to their low cost and flexibility.

7.Describe The Structure Of A Juice Filling Machine?

A juice filling machine’s construction is made up of a number of components, including:

Material Tank

Material tank is the station which holds juice that has to be filled in bottles. It is separately attached to the machine and transferred through pump.

Product Pump

Product pump is the part of machine who energizes the material inside tank and suck it through air pressure into filling station.

Control Panel

It is an electric case with a touch screen display, a number of buttons, including an emergency stop, power, and speed regulation buttons. The user may configure all the critical settings needed to process and run the juice filling machine using this control panel.

Filling Station

It is the core component of a juice filling machine to perform the task filling bottles with exact amount of material.

Filling Tubes

Filling tubes are attached with filling station. Through their narrow nozzles, filling tubes go inside the containers and fill them without wasting any drop.

Conveyor Belt

Conveyor belt work as a road for transporting your bottles. It takes the containers and drop them exactly under filling tubes. When these bottles get filled, conveyor belt start moving and discharge the filled bottles to another end.

8.What Are The Uses Of A Juice Filling Machine?

The following industries can help you comprehend the various uses of a juice filling machine:

Beverage Industry

The beverage business is one of the well-known sectors that is constantly in need of a juice filling machine. Manufacturers in this sector frequently use this machine to fill various sweet liquids, such as fruit juice, vegetable juice, smoothies, and other products. They may better maintain the quality of their beverages for a longer period of time by employing this machine.

Dairy Industry

The dairy sector, as its name suggests, processes milk as well as comparable products like cream, butter, condensed milk, etc. Due to its high standards for hygiene, packed milk is preferred by the majority of consumers. The dairy industry uses this machine to please their customers by offering superior packaging.

Wine Industry

Wine is a popular beverage that is primarily drunk in western countries. Fruits, sugar, and acids are the main ingredients used in making wine. Wine-processing businesses used to put it through a number of stages, with packaging being a crucial one. A juice filling machine is thus used for the filling of wine in bottles, cans and containers etc.

Food Industry

Food industry is the area where you would find every type of production from solid uncooked pasta to ready-made food and sauces. Among these various items, cooking oil, vinegar and liquid food additives. It means, that importance of a juice filling machine is also realized in this sector.

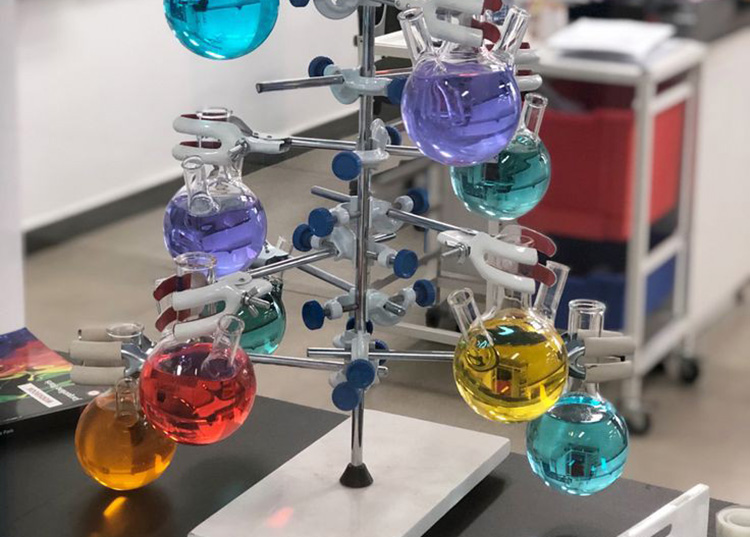

Chemical Industry

There are several uses for liquid chemicals in laboratories, educational institutes, and everyday products. Due to the fact that chemicals are hazardous, businesses that process them are also involved in the packaging process. A juice filling machine that correctly fills each bottle and upholds environmental cleanliness is highly regarded by the chemical industry for this purpose.

Pharmaceutical Industry

The pharmaceutical industry is the sector where pharmaceuticals are made. These medications come in both liquid and solid dosage forms. This machine is in charge of putting various sorts of syrups into bottles in this situation.

9.How Many Machines Of Juice Filling Are Available In Market?

Juice filling machines come in a variety of designs, and each has unique features. The information about these machines is as follows:

Piston Juice Filling Machine

A piston juice filling machine is the most typical form of juice filling machine. It is perfect for putting any kind of thick or thin juice inside bottles. It employs a cylinder to quickly fill juices and produce excellent results.

Components

A piston juice filling machine is consists of hopper, conveying system, stainless steel stand, cylinder, inlet and outlet valves, nozzles, filling station, temperature regulator and operating system.

Working Principles

The material is stored in the hopper located in the upper side of machine. After it get started, the material is sucked into the tubes and then delivered to bottles in an orderly manner.

Application

This equipment can perfectly fill your regular juices from free flow to viscous, including those having chunks of fruits.

Volumetric Juice Filling Machine

A volumetric juice filling machine is used to fill containers with a regular and precise amount of juice while requiring less maintenance. It is managed by an advanced servo system that efficiently operates by following a set procedure. This machine is perfect for filling thick fluid such as pulp of fruits and vegetables.

Components

The structure of machine is composed of durable stainless steel frame, adjustable filling station, detection system, material tank, hopper, speed regulator, conveying system, control panel and filling tubes.

Working Principles

The machine uses instructions that have been saved in memory slots, such as filling speed and quantity, etc. It begins precisely injecting the desired amount of juice into bottles after they have been transported by conveyor belt to the filling station. Following that, the filled containers are released using a guiding rail.

Application

It can be used to fill thick drinks like smoothies and mango, guava, peach, and apricot juices.

Digital Juice Filling Machine

This digital juice filling machine is semi-automatic and has a small footprint. This device is simple to use and consumes little electricity. It has a built-in material tank for which a gear pump is additionally used.

Components

It is made up of few components, including Silicone pipe, filling nozzle, material tank, and pump gear.

Working Principles

You may easily operate it by manually putting bottles under the filling nozzle. silicone pipe is used to fill bottles with the substance. The machine automatically stops when the appropriate level is reached, and the user then picks up the bottle to be capped.

Application

This device can be used for juices, cold beverages and sauces among other things.

10.What Is The Production Line For A Juice Filling Machine?

The entire production line is necessary if you are operating a fully fledged beverage or liquid processing enterprise in order to run your business successfully. For this reason, we have highlighted for you the crucial machinery that would complete your production line. They are:

Nitrogen Flushing Machine

You may already be familiar with the nitrogen flushing device, but if not, we’ll explain it to you now. A nitrogen flushing machine is a tool that may be used to flush nitrogen gas into empty or filled containers in order to prevent bacterial growth and increase shelf life by totally removing oxygen from the environment.

Bottle Capping Machine

Another crucial component of your juice filling production line is the bottle capping machine. Once all the bottles have been filled with juice or other liquids, they are transferred to a machine that caps bottles, sealing the mouths of the bottles by covering them with lids tightly.

Induction Sealing Machine

Sometimes simply capping a bottle is insufficient since the contents need to be hermetically sealed, which is done with an induction cap sealer. Aluminum foil is thus attached to seal the bottle lips using radiation to completely safeguard your product.

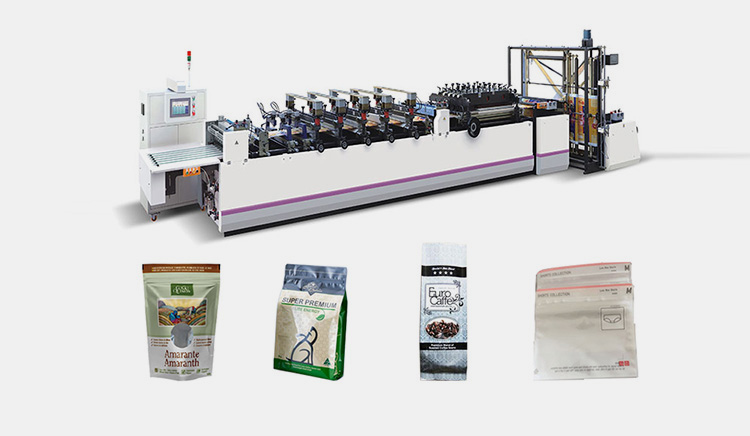

Pouch Forming Machine

As the information above makes apparent, you can pack your beverages in plastic pouches too. If you wish to employ plastic pouches in this situation, you will need a pouch forming machine, which will efficiently create lovely bags with an optional spout and resealable zipper for you.

Labeling Machine

The ability to print your company name, the high-quality ingredients you used in the product, and information about the product’s expiration date on labels helps your brand become well-known and stand out in the marketplace. For this purpose there is much machinery used for labelling, including ink printing machines, classic labelling machines, and shrink sleeve labelling machines.

11.What Are The Important Considerations For A Juice Filling Machine?

When selecting the best juice filling machine, you should never ignore some of the crucial considerations. These elements are listed below:

Product Type

What is the nature of your your product? Whether it is free flowing, viscous or having fruit pieces. After answering these questions, pick the machine as per your product requirement.

Type of Packaging Containers

Another factor to look for is the type of containers in which you are going to pack your juice. Because, these containers would ultimately affect your production line and filling equipment. For instance, cans require can seamer while as bottles need capping machine. Similarly, for narrow mouth containers you would use narrow filling tubes.

Desired Volume

Do you want to fill limited number of bottles, or you want to increase your production? For minimal production a semi-automatic juice filling machine is good. While as, for high volume production you should go for a fully automatic machine.

Cost

Everyone’s most valuable asset is money, which they never want to squander irresponsibly. Due to this, pricing should be taken into account when buying a juice filling machine. If you are new to the field, it is preferable to purchase a compact design machine at a fair price. Contrarily, choosing to spend a sizeable sum of money on equipment that is ideal for your flourishing firm

Conclusion

In conclusion, a juice filling machine is a highly effective piece of machinery for perfectly filling various sorts of beverages. Every industry admires its effectiveness and performance and wants to include it in their manufacturing process. The goal is to increase production while putting forth fewer efforts. If you share the same thoughts, don’t waste time debating; instead, take action by getting in touch with Allpack for an amazing juice filling machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide