Foot Operated Heat Sealer: The Top Buying Guide In 2025

Industries like food, agricultural, pharmaceuticals, packaging and others are using sealing techniques to increase their productivity and to make the product presentable.

Foot operated heat sealer is also one of the best sealing machines available. To assist the buyer in selecting right type of foot operated heat sealer, Allpack is providing a complete buying guide of it that includes all necessary information. Take the most!!

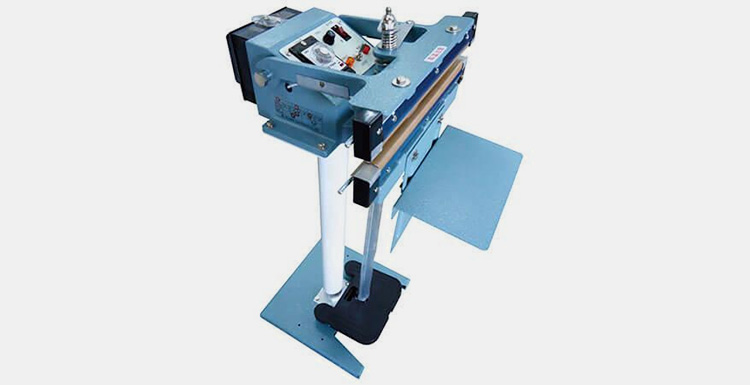

1.What Is A Foot Operated Heat Sealer?

Foot operated heat sealers are globally famous for sealing of products that are manufactured in small or medium scale industries. These industries use it for sealing their products with perfection and in a quick manner.

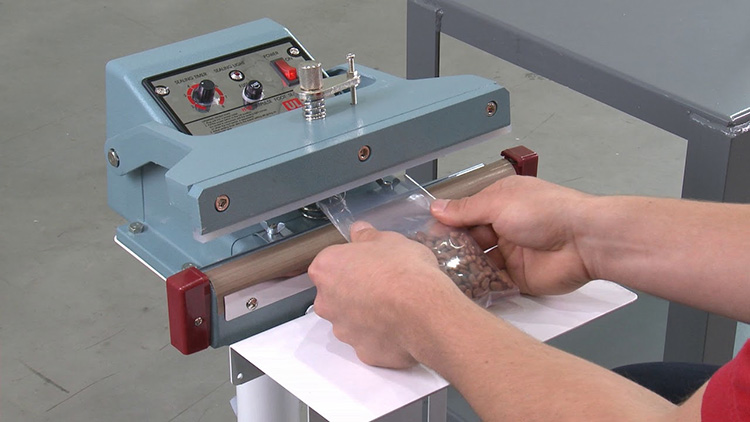

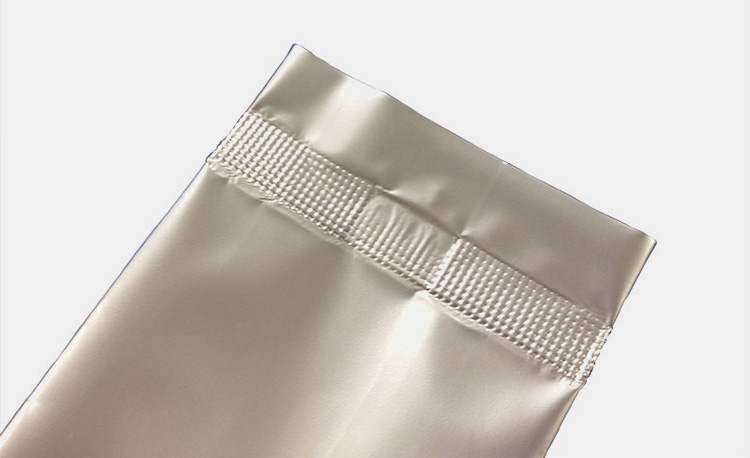

The bag is kept in between of both the jaws of foot operated heat sealer and then these jaws are joined together to perform sealing. An aesthetic finishing of sealed bags and pouches of paper, polypropylene, foils and waxed is achieved using a foot operated heat sealer.

2.What Are The Applications Of A Foot Operated Heat Sealer?

Foot operated heat sealers are used in packaging of products that are manufactures in industries like medical, food and pharmaceutics. Their application in such industries is as follow

- Medical Industry

Foot operated heat sealers are used in medical industry to seal instruments, utensils and other equipment in bags made up to polythene, plastic or film. This ensures safe handling of equipment whenever required and also keeps them safe from bacterial or environmental attacks.

- Food Processing Industry

Food processing industry uses foot operated heat sealer for sealing of pouches and bags that are filled with eatable materials. The machine helps the industry to produce high quality and efficient sealing of products so that they are safe from contamination and also make the customer feel pleasant with its finishing

- Pharmaceutical Industry

Medicines, drugs and sometimes liquid syrups are filled in bags made up of plastic, aluminum film or polythene material and then sealed using a foot operated heat sealer. There are wide uses of heat sealers in a pharmaceutical industry and are mostly are used due to their better productivity and easy handling

3.What Are The Working Principle Of A Foot Operated Heat Sealer?

A foot operated heat sealer has a simple operation. It follows following steps.

- Initially, the parameters like temperature, heating cycle and speed of foot operated heat sealer are set to standard or according to the material on which sealing is carried out.

- As the parameters are ensured, bags or pouches of different materials are kept on the bottom jaw of a foot operated heat sealer.

- Afterwards the operated pushes down the pedal, both the jaws get in contact and sealing is done due to heat bonding of both jaws.

- As a result of this heating, the material melts and proper sealing is carried out.

- When the cycle is completed, an alarm indicated the finishing of process and the operator removes its foot from the pedal. Both the jaws get separated and the finished product is taken out of the foot operated heat sealer.

4.What Are The Main Components Present In A Foot Operated Heat Sealer?

Main Components of a Foot Operated Heat Sealer

The main components of a foot operated heat sealer are

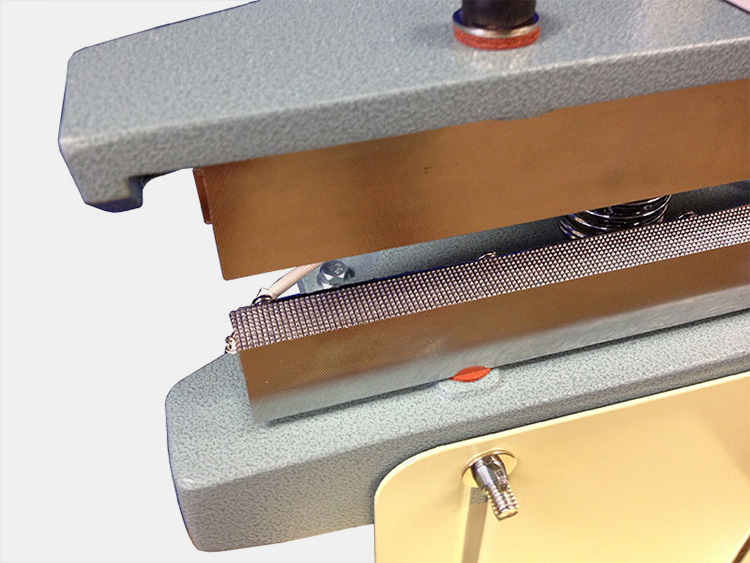

- Jaws

The most important part of a foot operated heat sealer are its top and bottom jaws. These are actually responsible for sealing of products. The product is placed in between of these jaws and during operation both these jaws get in contact which in result seal the material

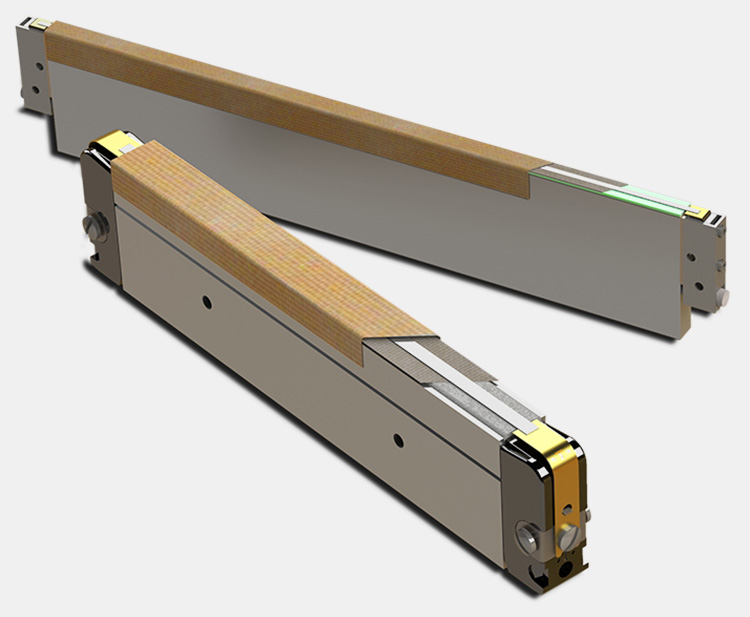

- Heating Element

The temperature is maintained at the heating elements of a foot operated heat sealer. These are on the jaws of machine and are responsible to melt the product with the produced heat. The product placed at the jaws gets its sealing temperature from these heating elements. Different type and shaped heating elements are present in different types of foot operated heat sealers according to the requirement of product.

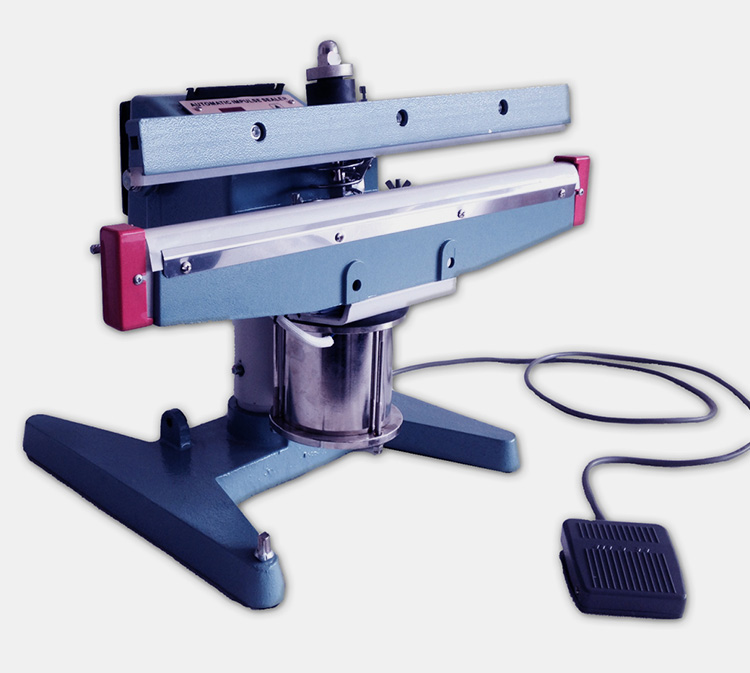

- Pedal

Pedal is the most important part of a foot operated heat sealer as it is responsible for the operation of machine. The operator pushes the pedal downwards and as a result an electrical signal is transferred to joint both the jaws. When the foot is removed from the pedal the jaws get separated. Pedals basically convert a mechanical signal to electrical one

- Control Panel

The operation of a foot operated heat sealer is controlled through this control panel. All the knobs and buttons like power, temperature control, regulator, switches and fuses are present in the control panel. It is in direct control of the operator and from here the operational parameters are maintained.

- Temperature Sensors

Heat sensing temperatures are found mostly in machine where temperature or heating factor is involved. Such sensitive devices are also found in automatic foot operated heat sealers because the machine has to be maintained at the given preset value. If the sensors do not perform well, the over-heating of jaws can cause irregular sealing and severe material loss.

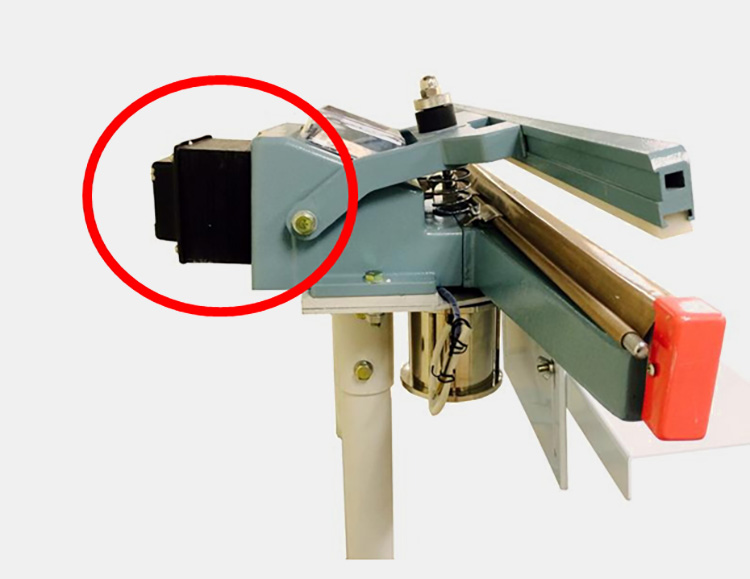

- Transformer

A transformer basically controls the over and low voltage of a foot operated heat sealer and maintains the power throughout its operation. During a sudden jerk of voltage, the foot operated heat sealer can directly get affected. This is the reason a setup transformer are ideally installed in it.

5.What Types Of A Foot Operated Heat Sealer Are Available In Global Market?

Foot operated heat sealer have various application and according to it they are designed and constructed. In the global market there are three types of foot operated hand sealers that are fulfilling sealing demand of processing market. The types of a foot operate heat sealer are

- Double Sided Foot Operated Heat Sealer

A double-sided foot operated heat sealer is compatible with almost every type of material. As the foot pedal gets activated by the operated, both top and bottom side gets in contact in this type of foot operated heat sealer. This ensures sealing of wide range of materials including vinyl which was difficult to seal in earlier times. A seal width of 5mm can be achieved in a double sided foot operated sealer.

- Single Sided Foot Operated Heat Sealer

This type of foot operated heat sealer is the most efficient one used in packaging of variety of packages. They are used for packaging of small pouches to heavy materials with a thickness of 6 to 10 mm. Hands free operation is carried out in a foot operated heat sealer and allows a seal width of 5mm.

- Constantly Hot Foot Operated Heat Sealer

Industries where processes are carried out every time use constantly hot foot operated heat sealer. These machines allow quick sealing of products with strong hermetic sealing. A constantly hot foot operated heat sealer allows more sealing width as compared to the rest two which is around 5 to 10 mm.

6.What Materials Are Used To Seal In A Foot Operated Heat Sealer?

There are various materials that are frequently applied in the foot operated heat sealer including plastic bags, polypropylene sealing aluminum foil, etc. Here are the details as following below:

Foot operated heat sealers are widely used to seal materials like plastic, aluminum foil and polypropylene. However sometimes paper bags are also used in industries for packaging of products. The specifications of these materials according to their sizes are

- Plastic Bag

One of the most commonly used material for packaging purpose is plastic or polythene. They are highly recommended due to the versatile behavior of carbon and hydrogen bonding which makes it very hard to break. A foot operated heat sealer also seals a plastic bag which ranges between 5 to 10mm depending upon the temperature set for sealing.

- Plastic / Polypropylene Sealing

With more than 20 mm of thickness, polypropylene bags are the thickest ones which are sealed using a foot operated heat sealer. They require high temperature for their sealing as their melting point cannot be achieved at low temperature

- Aluminum Foil

After plastic bags, aluminum foils come second in terms of packaging purpose. Mostly food and agricultural products are packed in these types of materials to keep them safe. An aluminum foil of 10 to 15mm can be easily sealed using a foot operated heat sealer.

7.What Benefits Can YouGet From A Foot Operated Heat Sealer?

With various advantages of the foot operated heat sealer, you can fulfill your household purposes or you can bright your business. Some of the advantages of foot operated heat sealer are

- Safe Product Delivery

Sealing through a foot operated heat sealer ensure proper protection to the product which is kept inside the bag or pouch. Products that are affected by environmental conditions are protected from being contaminated and also increase their shelf life.

- Presentable Packaging of Product

A foot operated heat sealer provides decent and presentable sealing properties which are loved by the customers. Neat and clean packaging attracts the customer more towards the product and can increase its demand.

- Continuous Sealing

One of the biggest advantages of using a automatic foot operated heat sealer is that it provides continuous sealing options. The jaws of machine remains activated throughout the process at the same temperature which is preset at the start. This temperature allows sealing of any type of bag or pouch no matter it is made up of any material

- Cost Saving

One of the supreme advantages of a foot operated heat sealer is that it saves a lot of money. Packaging only includes a onetime investment on machine which actually is very economical. No extra investment is to be done as the maintenance cost of sealer is also very low.

- Easy to Adjust

The durability of a foot operated heat sealer can be judged in a way that they can easily be carried from one place to another without any support. As per their requirement, the manufacturer can change their directions. Foot operated heat sealers are also applicable in all type of industries where packaging of products is done.

- Saving of Time

Once the temperature is achieved on both top and bottom jaws of foot operated heat sealer, sealing process is done in a highly quick manner. This saves a lot of packaging time as compare to sealing done through manual process.

- Ease In Operation

Operation of foot operated heat sealers is easy to understand and requires no prior knowledge. The operator can get use to the operational procedures once he gets hands on to the machine.

- Versatility

A foot operated heat sealer offers sealing of variety of materials like paper, film, polypropylene and other which makes it highly compatible. Also it is not affected by any environmental conditions due to its quality structure.

- Smooth Production

Foot operated heat sealers are highly productive for small and medium scale industries, as they can seal more than 15 to 20 bags or pouches in a minute.

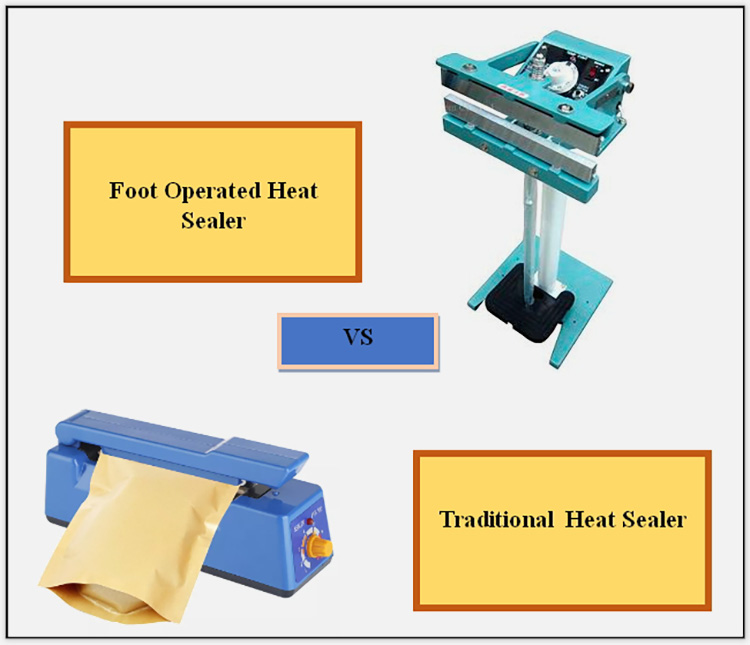

8.What Are The Differences Between A Foot Operated Heat Sealer And An Ordinary Heat Sealer?

Following are the differences between a foot operated heat sealer and an ordinary or traditional heat sealer.

- Pressure

Foot operated heat sealer is set on a certain pressure value which remains same throughout the cycle. This results in identical sealing on all the products. Pressure also maintains the force by which both the jaws of machines get in contact. This controlled pressure reduces chances of poor sealing

While in a traditional sealer the pressure varies in each cycle depending upon the operator’s ability. The applied pressure is directly in control of the operator. As a result to this, the product shows different sealing width in each cycle.

- Sealing Quality

High quality sealing is achieved in a foot operated heat sealer. Every product in the processing line has same sealing quality.

Poor quality sealing can be done manually. In this type of machine the cycle can be repeated more than twice depending on the quality of sealing done. A lot of wastage can occur in manually operated sealing machines.

- Wide Range

A foot operated heat sealer offers wide range of material compatibility and can be set according to the width of bag. Different materials like PVC, polyethylene, aluminum foil and other materials of various sizes can easily be sealed using this type of machine.

Single machine only shows compatibility to limited material width. The manufacturer has to buy separate machine for all products. Also the machine does not gives efficient sealing if variety of materials are used.

- Economical

Foot operated heat sealers are a bit expensive when compared with manual sealing machines but they can be economical in a sense that only one-time investment is carried. After that a full time benefit can be taken for longer period.

Manual machines are economical when bought but when each machine are purchased for separate material it requires a lot of initial investment. Even thickness and width of materials are also kept in concern when a manufacturer thinks of a traditional heat sealer.

- Productivity

The productivity also remains a greater advantage and large number of sealed products can be get from a foot operated heat sealer.

The machine depends upon the ability of its operator. The greater the operator is efficient the maximum output is gained. It always remains a direct relation in traditional sealers.

- Edge Cutting

Sharp knives and heating elements are present in a foot operated heat sealer to cut the bag after its sealing process is completed.

Manually cutting of edges is done by the operator himself. The cutting can be sometimes poor with improper edge cutting.

9.What Common Errors Are Found In A Foot Operated Heat Sealer?

When you are operating the foot operated heat sealer, there may be some common errors sometimes. You do not have to worry about this things, and here are the common errors in the operating process and its remedies. Your problems will be well managed if you after this guide.

| S.NO | PROBLEM | CAUSE | TROUBLESHOOTING |

| 1 |

Poor Sealing |

Incorrect sealer temperature | The most important factor of poor sealing is insufficient temperature. The temperature should be checked properly before starting of packaging. |

| 2 | Excessive pressure | Reduce the pressure by the pressure knob present on the control panel. | |

| 3 | Insufficient pressure | Increase the pressure by the pressure knob present on the control panel. | |

| 4 | Insufficient sealing width | Check both the top and bottom jaw of the machine and its sealing width according to the width of material. | |

| 5 | Misalignment of jaws | Check both the jaws and align them accordingly | |

| 6 |

Poor Cutting |

Improper adjustment of anvil | Adjust both the cutting knife and the anvil |

| 7 | Difference in jaw temperature | Check temperature of both jaws of a foot operated heat sealer and adjust it according to the requirement | |

| 8 | Improper cleaning of jaws | Cleaning the jaws properly before start of production. | |

| 9 |

Open Ended Seal |

Sticking of film on jaws | Check temperature of both jaws and adjust it according to the requirement |

| 10 | Jaws not heating | Check circuit breaker, heater, thermistor, bushes and relays. | |

| 11 | No pause when jaws are meshed together | Set the cycle to the standards according to the material | |

| 12 | Jaws not properly pressing the bag | Raise the bottom jaw to a certain height so that both jaws press together in a proper manner |

10.What Important Factors Are To Be Observed Before Buying A Foot Operated Heat Sealer?

Following factors should be considered before purchasing a foot operated heat sealer.

- Initial Investment

There are number of foot operated heat sealers that have different cost. That is why the buyer should select the machine according to its investment keeping the production in view.

- Production Requirement

Before purchasing a foot operated heat sealer, the buyer should thorough study its requirement and product capacity. This will help an industry to select a sealer according to its capacity. Machine with extra burden can somehow cover a large area and give no proper output.

- Quality of Jaws

One of the important factors related to foot operated heat sealer is the quality of jaws which are actually responsible for sealing. A close study should be done related to these jaws because if they are made up of poor quality material then they won’t last for a longer period and will require quick replacement. Also they must be compatible with the temperature at which the manufacturer aims to seal its products. Excess temperature can melt the jaw as well as the packaging material.

- Maximum Sealing Width

Foot operated heat sealers are found with different sealing width. It is important to notice that whether the product that is to be sealed can be processed in it or not. Sealing machines with maximum width are ideally to be selected as they can merge all ranges within it.

- Cooling Time

After sealing process is carried out, cooling down time is carried out. This is also an important thing as low cooling time increases the productivity. Machines with greater cooling time slows down the process and also give poor quality sealing.

Conclusion

Foot operated heat sealers are efficient and provide quality sealing. To better understand all the basic things related to a foot operated heat sealer we Allpack are providing you this buying guide and are available 24/7 for your assistance. If you still find any query you can directly contact us or visit our website http://www.allpackchina.com/ .

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours