Bottle Sealing Machine: The Complete Buying Guide in 2025

Sealing multiple types of bottles & cans is not an easy thing when you do it manually, but there are some handy tools for this kind of operation.

Bottle Sealing Machine is one of the powerful & accurate tools that you can implement with your business line for sealing bottles etc.

You do not have to think or worry about how I can get the right bottle sealing machine and how you can operate it without any difficulty because this righteous guide is going to explain each and every key point about the bottle sealing machine.

1.What is Bottle sealing machine?

Bottle Sealing Machine

A bottle sealing machine is a device that helps to seal bottles airtight. This is done by using heat to melt a small amount of plastic onto the rim of the bottle. Bottle sealing machines can be used for a variety of purposes, such as canning food or preserving liquids.

The purpose of this seal is that it creates a hermetic seal that will keep contents fresh and prevent leakage. The equipment seals the bottles automatically. So, basically the bottle sealing machine is used to close the face of the bottle by putting the hermetic seal on it.

2.How the bottle sealing machine works?

A bottle sealing machine is a device that is used to seal the opening of a bottle. The machine typically consists of a heated element that melts a small amount of plastic, which is then used to seal the bottle.

Working Principle

Bottle sealing machines work by heating up a small amount of plastic until it is melted. The molten plastic is then used to seal the opening of the bottle. The heat from the machine helps to keep the plastic in a liquid state so that it can easily be applied to the bottle.

After the plastic has been applied, the machine will cool down the plastic to harden and create a seal.

The bottle sealing machine works automatically. It finishes all the steps automatically from the preparation of sealing material to the end of the sealing process.

3.What are the advantages of bottle sealing machine?

When it comes to packaging beverages, bottled water is one of the most popular products on the market. And, a bottle sealing machine can offer a number of advantages for businesses that package and sell bottled water. Here are just a few of the benefits that a business can enjoy by using a bottle sealing machine:

Increased Efficiency

Efficiency

Bottle sealing machines can help to increase the efficiency of your bottling process. This is because these machines can quickly and easily seal bottles with a tight seal. This can help to reduce the amount of time that it takes to package your products.

Enhanced Appearance

A well-sealed bottle can also offer a more professional appearance than a product that is not sealed properly. This can give your business an edge over competitors who do not use bottle sealing machines.

Improved Shelf Life

Sealing bottles with a tight seal can also help to improve the shelf life of your products. This is because sealed bottles are less likely to leak, which means that your products will stay fresher for longer periods of time.

Reduced Costs

Reduced

Investing in a bottle sealing machine can also help you to reduce your overall packaging costs. This is because these machines can help you to save on materials, such as labels and tapes, that are needed to properly seal bottles.

Easy To Operate

The bottle packaging machine is very easy to operate. You just have a small knowledge about the working of the equipment. After that, you can easily operate the machine.

Fast to work

The bottle sealing machine is very fast. It quickly seals the bottle. As it seals more bottles in very less time due to its automated function.

4.How many types of Bottle sealing machines are available?

A bottle sealing machine is a device that is used to seal bottles. There are many different types of bottle sealing machines available on the market, each designed for a specific type of bottle and application.

Manual Heat Bottle Sealing machine

Foil Heat Sealer

The most common type of bottle sealing machine is the heat sealer. Heat sealers work by heating a strip of foil or film that is placed over the mouth of the bottle.

The heat from the sealer melts the foil or film, creating a tight seal around the bottle. Heat sealers are typically used for plastic bottles, but can also be used for glass or metal bottles.

Working

The working of heat bottle sealing machine is very simple and convenient as compared to the other bottle sealing machine as it is a manual bottle sealing machine.

It will only take you place the bottle in the desired position and then you take the heating handle and place on the bottle head with a cap on it.

Advantages

Less expensive and affordable for low level production.

Manual handling so any one can operate easily.

Very common in small industries and household purposes.

Disadvantages

Not that good to work with large production.

Sometimes you will face sealing problems that will require technical skills to solve.

Working Parts

In a manual heat bottle sealing machine there are some very common parts that you must know and these are.

Sealing unit/assembly

When the cap is installed at the top of the bottle the sealing unit performs the sealing action.

Powering unit

In this unit a motor is attached in the base that converts the electrical energy into mechanical one to power the different other parts as well as heating unit.

Heating line

It will be hard to seal caps on the bottles without heating because heating lower the density of plastic and make it melt to seal appropriately.

Induction Bottle Sealer

Another type of bottle sealing machine is the induction sealer. Induction sealers work by inducing an electromagnetic field that creates a magnetic field around the neck of the bottle.

The magnetic field seals the bottleneck, keeping the contents of the bottle fresh and preventing leakage. Induction sealers are typically used for metal bottles, but can also be used for plastic or glass bottles.

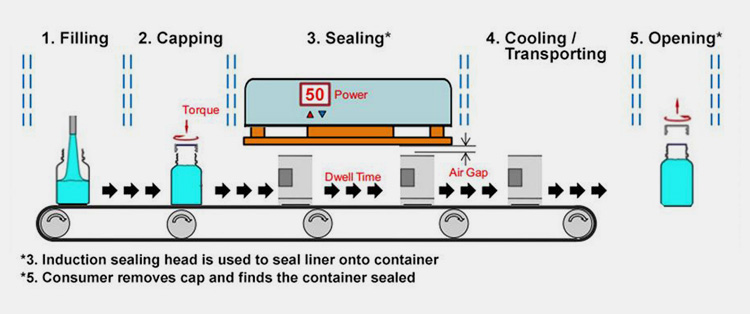

Working

An induction bottle sealing machine is also works in the same way a heat sealer works but all the induction bottle sealing process is done in a contact free way.

Hermetic seal is produced when the sealed bottle passes through the assembly to make a contact free sealing through induction unit.

Advantages

Less chances of your product getting damage

Contact free sealing in a hygienic way.

Very competitive and reliable machine.

Disadvantages

Hermetic seal sometimes not work perfectly.

Require some great investment and installation process.

Working Parts

An induction bottle sealing machine have some following main working parts.

Conveyor Line

It simply conveys a product from one part to the other for sealing purpose.

Induction Unit

By providing a contact free sealing induction unit gives you the stable capped bottles in a hermetic way.

Collection Unit

After the sealing is done and your bottles are ready to come out a collection bucket installed at the end make sure you get required product without any damage after the sealing.

Vacuum Sealer

Vacuum Sealer

Finally, there are vacuum sealers. Vacuum sealers work by removing all of the air from inside the bottle and then sealing the neck of the bottle with a tight-fitting cap.

This creates a vacuum-tight seal that prevents oxygen from getting into the bottle and spoiling its contents. Vacuum sealers are typically used for wine bottles, but can also be used for other types of bottles.

Working

In a vacuum bottle sealing machine all the bottles coming inside the sealing unit are first placed under the vacuum suction unit where vacuum creation takes place that sucks the air first.

In this way the vacuum suction erases the air and then the sealing takes place to make your product quality outrageous.

Advantages

Very useful when you want to give long lifecycle to your products.

Effective to handle large and bulk production.

Careful production with safe environment.

Hundred percent leakage free products with soft handling.

Disadvantages

A bit expensive but on a positive note worth it.

Require some common technical skills for operation.

Working Parts

Vacuum bottle sealing machine working components are these.

Control panel

This part gives you an edge to control multiple processes at a single shared view giving you an outlook about your machine.

Vacuum suction head

Any kind of vacuum produced inside a bottle with the movement of liquid is clarified with this component.

5.What are the main working components of a bottle sealing machine?

The bottle sealing has some main components. These main components are as follows:

The Conveyor Belt

Conveyer Belt

The first component of the bottle sealing machine is the conveyor belt. The conveyor belt moves the bottles through the machine and into position for the heat sealer.

The Heat Sealer

The next main component of a bottle sealing machine is a heat sealer. The main function of a heat sealer is that it seals the bottle caps onto the bottle.

Cooling System

The cooling system is the most important part of the bottle sealing machine. The cooling system cools the sealed bottles so that they are ready for packaging.

Sealing System and Head

Sealing System and Head

The sealing system is there to do arrangements and bottle sealing. This is also considered an important part of the machine.

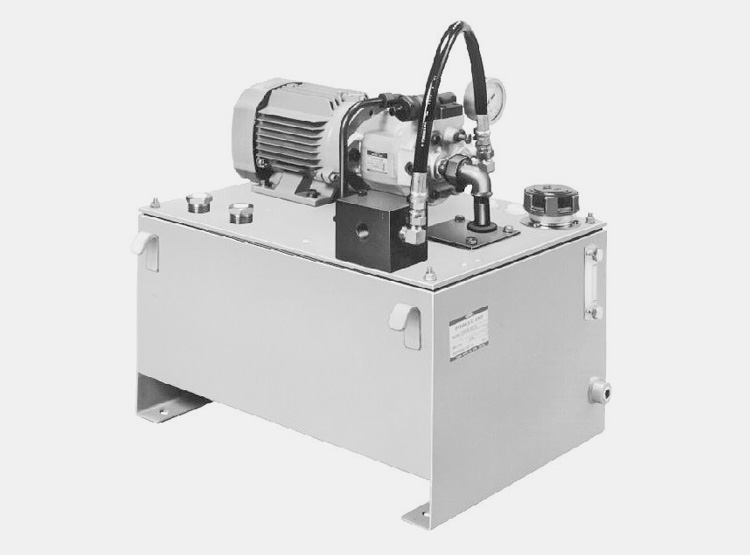

Power System

The power system of the bottle sealing machine is used to provide electricity to the equipment. With this electricity, the machine starts working.

6.In which industries bottle sealing machine is used?

Bottle sealing machines are used in a variety of industries, including the food and beverage industry, the pharmaceutical industry, and the cosmetics industry.

The Food and Beverage Industry

For food

The food and beverage industry is one of the biggest users of bottle sealing machines. This is because it is important to keep food and beverages fresh and free from contaminants. Bottle sealing machines are used to seal packages of food, such as cans and boxes, as well as bottles of beverages.

The Pharmaceutical Industry

The pharmaceutical industry also makes use of bottle sealing machines. This is because it is important to ensure that pharmaceutical products are not contaminated. Bottle sealing machines are used to seal both containers of pharmaceuticals and individual doses of medications.

The products you can seal with the bottle sealing machine are different types of syrups, medicines, etc.

The Cosmetic Industry

The cosmetics industry also relies on bottle sealing machines. This is because it is important to keep cosmetics fresh and free from contaminants. Bottle sealing machines are used to seal containers of makeup, shampoo, lotion, and other cosmetics products.

7.What types of bottles you can seal using a bottle sealing machine?

There are many types of bottles that you can seal using a bottle sealing machine. These are as follows:

Screw-top Bottle

Screw top bottle

The most common type of bottle is the screw-top bottle. These bottles have a threaded neck that fits into a corresponding thread on the lid of the bottle sealing machine.

Swing-top bottles

The second type of bottle is a swing-top bottle. This type of bottle is mainly reusable bottle. This has a great durability level.

Corked Bottles

Corked bottles are used for filling the wine in them. So, wine drinkers purchase the cork bottles.

Twist-off Bottles

Twist Of Bottle

The last type of bottle that you can seal by a bottle sealing machine is a twist-off bottle. This bottle provides a secure and better seal. It has a longer shelf life.

8.Is it possible to seal a metal bottle with the help of a bottle sealing machine?

Yes, there are some kinds of bottle sealing machines that you can use to work with metal bottles although, it is a tough ask but you can do it with comfort and ease.

Metal bottles are hard to work with but there are some bottle sealing machine that you can use to work with for instance, aluminum bottle sealing machine is one of the kinds that can be used to seal hard metal & aluminum bottles.

Another kind of bottle sealing machines is metal bottle sealing machine which is designed specifically for this kind of task so, if you have any business or production line for metal bottle sealing you can benefit from this one as well.

9.What is the importance of having a bottle sealing machine for your business?

Having a bottle sealing machine for your business can add some great values for your business in many ways.

Trust & Satisfaction for Customers

If you are running a B2B or a B2C company then addition of this machine in your company will increase your trust because it will provide quality production.

By giving you quality and efficient production this machine will increase your customers trust on you and after their satisfaction they will definitely come to you as a future perspective customer.

Greater Production & More Market Value

If you provide quality and secure products to the potential buyers they will tell the others about it and this way your company will get a recognition in a global market.

It will also be easy for you control bulk production because bottle sealing machine will help you in this regard.

10.How you can troubleshoot common bottle sealing machine?

While working with bottle sealing machine there will be some cases when you will face some problems but it is important for you to know that how you can handle these problems.

Unsealed Caps

This kind of problem occurs when your sealing unit face a rotational problem or sealing caps are not getting the required torque.

To solve this problem you need to make the machine provide the required torque by setting assembly part to rotate in the required direction.

Bottles getting damage

During the sealing a bottle holder line holds the bottle with metal bars and when you increase the holding pressure then you will get damage bottles.

Always set the holding pressure up to a moderate value to ensure safe bottle sealing.

Extreme Sealing

A bottle when sealed with a cap on top of it you might sometime notice that it is very hard to break the seal of the cap.

And to avoid this unprofessional sealing problem you need to decrease the sealing power because increment in the sealing power will make very strong sealing.

It also happens because of liner which is of greater size than the bottle neck.

Conclusion

A bottle sealing machine is a versatile tool that can be used for a variety of purposes. Whether you’re looking to seal bottles of water or wine, or even just store some loose screws and nails, a bottle sealing machine can help you get the job done quickly and easily. We hope this guide has helped you understand a little more about what bottle sealing machines are and how they work, as well as give you some ideas on how you can use one in your own home or business. Allpack is the best provider of the bottle sealing machine in the market. If you have any questions regarding the bottle sealing machine you can contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours