Vacuum Feeding Machine: The Complete Buying Guide in 2025

Are you looking for a vacuum feeding machine? Does your business confront the challenges of product waste or slow conveying? Choosing a right machine sometime becomes a little bit hardscratcher.

All you need to do is to bring this innovative vacuum feeding technology into your manufacturing. With its efficient and clean feeding processing a vacuum feeding machine is the answer to all of your questions. How will you get to know its functions, applications and benefits are what we have described below in detail.

1.What Is A Vacuum Feeding Machine?

A vacuum feeding machine is the most ideal, improved and new invention of modern technology that is employed to deliver bulk materials such as powder, granules, pellets, flakes, and many other small particles. Through dust-free close pipe it generates fast conveying process ensuring zero environmental pollution.

Moreover, its modular design enables the quick connection of vacuum loader with other bagging machine and assures the damage free flow of fragile items during transport.

2.How Does A Vacuum Feeding Machine Work?

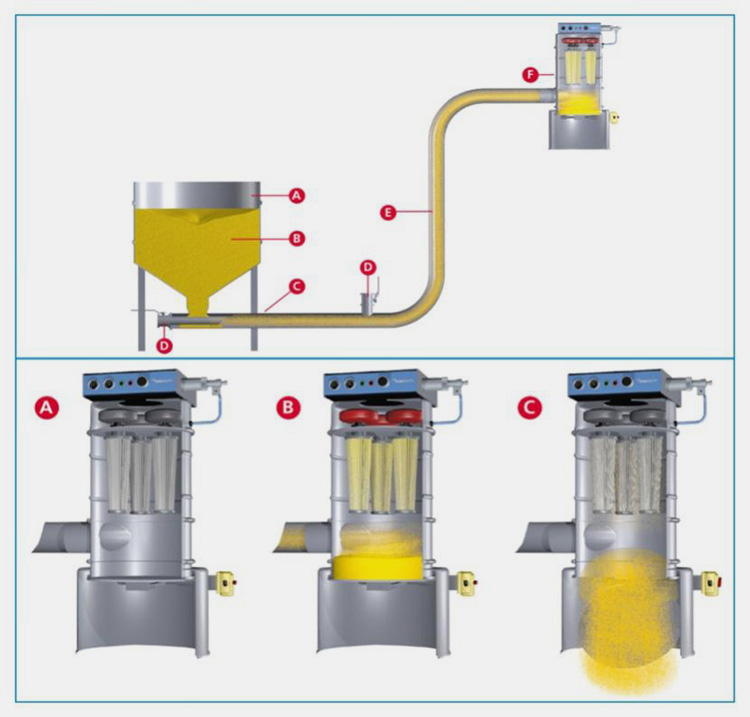

A vacuum feeding machine works by the predetermined procedure that is sequencially explained below in detail:

The initial process starts when vacuum pump creates negative pressure inside the vacuum housing while bottom valve is closed. Through inlet modular air is sucked from the pipeline connected with feeding station which generates the airflow and ultimately starts the movement of particulate material.

The vacuumed air produces swirling motion of particles which adheres to the filters fitted upward in vacuum suction feeder and accumulates all the depositing material in separating containers/filters.

At same time, air shocks are produced by tanks each connected to a filter and completely separates the gas, dust and raw materials. When the required transport time is realized the vacuum pump switches off, the valve of hopper is opened and material is delivered to receiving vessel through the hose of hopper. The air compressor immediately cleans the filters and the same process goes on in rhythm until it is desired.

3.What Are The Key Components Of A Vacuum Feeding Machine?

Some of the major components which together form the structure of a vacuum feeding machine are mentioned below:

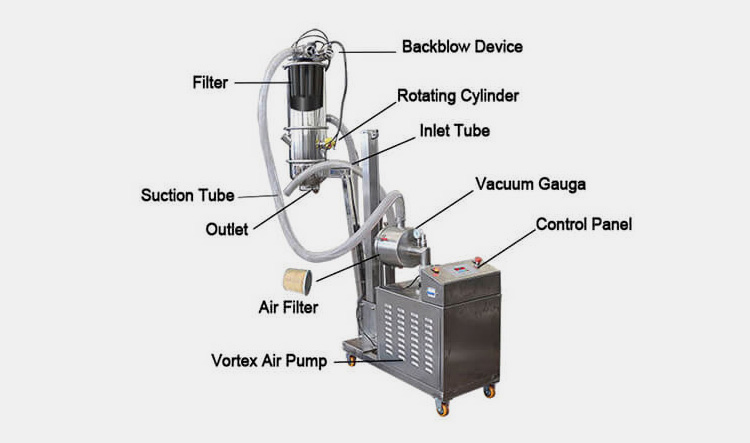

Vacuum Pump

It is the main part of any vacuum feeding machine which produces the false air in order to accelerate the movement of materials present in machine.

Hopper

It is the collection tank of machine with lower free flow valve for releasing load. All the material is gathered in its pure form in hopper. After completing each cycle of vacuum feeding the hose of hopper is opened to deliver bulk.

Filter System

Filters are located inside the vacuum feeding machine and are used for the processing of loaded particles. They separate material from air and removes dust and waste from them.

Air Compressor

This component of machine plays an essential role in providing neat, safe and healthy environment for goods’ processing. When the load is released from hopper air compressor quickly clean the filters with back flow pulse.

Control Device

Another core part of vacuum feeder is the control system which enables you to set the parameters like product amount, time and flow of air required for material operation. Once you have fixed the measurements, machine will take the instructions and work automatically.

Product Intake

It is the product feeding station where bulk materials are loaded before their transportation for operation. Material can be directly entrained from this plant into vacuum feeding suction.

Suction Tube

This tube is either made up of flexible plastic or stainless steel whose function is to sucked the air. Eventually the air grabs loaded material from feeding station and move it towards vacuum conveyor.

Ball Valve

It is located inside the suction tube which helps to adjust the amount of air by increasing or decreasing its level.

Transport Line

Transport line is the bridge between feeding station and actual vacuum conveyor. It consists of the vacuum-tight pipeline through which items are transferred to inlet modular of vacuum feeder.

Receiving Vessel

Receiving vessel is usually a container placed under the hopper of vacuum feeder. When the material is passed through complete procedure the contamination free products are then delivered to receiving vessel.

Wheels

An essential part which every machine requires for easy mobility is exactly the movable wheels. They are located under the machine with 360° degree movement strength.

4.Which Type Of Material Can Be Feed by A Vacuum Feeding Machine?

A vacuum feeding machine is capable of dealing enormous bulk materials including powders, granules, liquids and many others highlighted as under:

Powders

A vacuum feeder can be used with great advantage for dry powder products such as chemicals, spices, milk powder, wheat flour, dyes etc.

Liquids

Liquids like acids, oil, milk, ketchup etc can be conveyed by this innovative machine. These liquids are processed under moderate temperature to ensure safe and fine feeding.

Granules

Different products under the category of granules are perfectly eligible for feeding by a vacuum feeding machine. For instance sugar, glucose, sand, ceramic abrasive, and fertilizers are easily feed by this machine.

Pellets

Pellets are small round shape items usually of food, wood, medicine or clay which needs neat atmosphere for transportation that can be ideally done by a vacuum feeding machine.

Flakes

A vacuum feeding machine is designed in such a way that it can handle the feeding of flakes materials like wood particles, neoprene chips, food flakes of corn, chocolate, cereal etc.

5.What Are The Applications Of A Vacuum Feeding Machine?

A vacuum feeding machine has diversity in its application whether food or non-food industries its presence can be found in almost every second manufacturing firm that is associated with small particle production. In this way, few areas of its applicablity are taken below:

Agricultural Industry

Due to the vast production of seeds, grains and fertilizers agricultural industry is vigorously taking the services of a vacuum feeding machine to fulfill these tasks.

Food Industry

Among various other interprises food industry is highly influenced by this new technology of vacuum feeding. For feeding different items such as food additives, cereals, condiments, coffee beans, candies and liquids this machine has been used on great extent.

Pharmaceutical Industry

Thousands of pills, capsules and nutrition additives are produced everyday with need for proper feeding and packaging. To accomplish such highly responsible task an automatic vacuum feeding machine is brought into service which process unlimited medicines with precise temperature control while preserving their sensitivity.

Chemical Industry

Many chemical firms are using this machine for feeding acids and chemicals including hydrofluorosilicic acid, hydrochloric acid, copper sulfate solution, aluminum sulfate and emulsion polymers.

Metal Industry

For the feeding of various powders and granules like zinc powder, aluminum powder, silver powder, copper electrodes, metal industries are looking for the efficient functioning of vacuum feeder.

Pesticide Industry

Drugs which are used to kill insects especially to protect the growth of plants and crops are known as pesticides. Large number of industries in this field are utilizing vacuum feeding machine to securely convey the hazardous substances without leaving any effect on surrounding.

Pigment Industry

Use of a vacuum feeding machine can be traced in pigment industries. Different types of dyes, colorants, organic and inorganic pigments are effectively conveyed by this machine.

6.Explain The Essential Features Of A Vacuum Feeding Machine?

A vacuum feeding machine has been praised with numerous qualities which have been highlighted below:

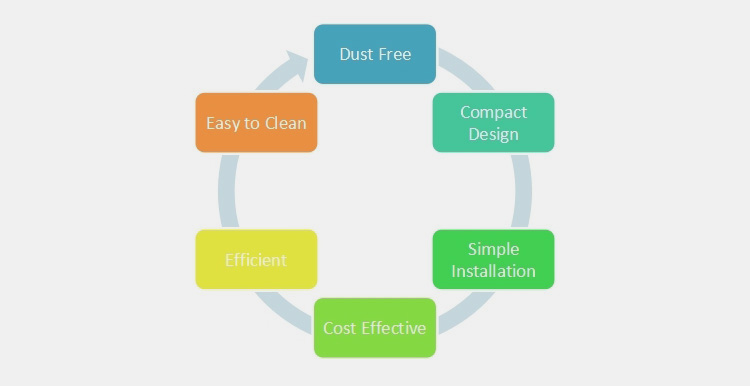

Dust Free

It provides clear, safe and dust free environment to easy flow of materials and thus retain their original quality. By performing quick cleaning when products are changed this machine is very hygienic.

Compact Design

Its ergonomic structure is made up of durable stainless steel along with fully enclosed delivery system is pressure resistant ensuring anti-corrosion and pollution free feeding. It also reduces the leakage possiblity of materials and is suitable for mobile use.

Easy to Clean

The parts of machine can be easily separated. Moreover, the air compressor inside machine automatically cleans the feeding filters after the completion of each cycle.

Efficienct

Its most important characteristic is the strong capacity and level of efficiency it shows during operation. The effective stratification of powder and other items without any noise make it more desirable for commercial use.

Cost Effective

It reduces the labour intensity and energy consumption by fast discharging and low operational cost.

Simple Installation

With modular design a vacuum feeding machine do not require head corner installation and is easy to install. Any layman can simply operate it by reading the description and usage method.

No Product Loss

Use of vacuum feeding machine can give you lots of benefits among which most crucial is that it save your products from being wasted during operation.

Low Power Consumption

As it uses vacuum pump for air rather than electric supply to operate a machine this will consume less power and energy.

7.Explain In Detail The Types Of A Vacuum Feeding Machine?

A vacuum feeding machine can be divided into two major types. Every vacuum feeding machine is either dilute phase or dense phase. To know both of them well look into the comprehensive details given below:

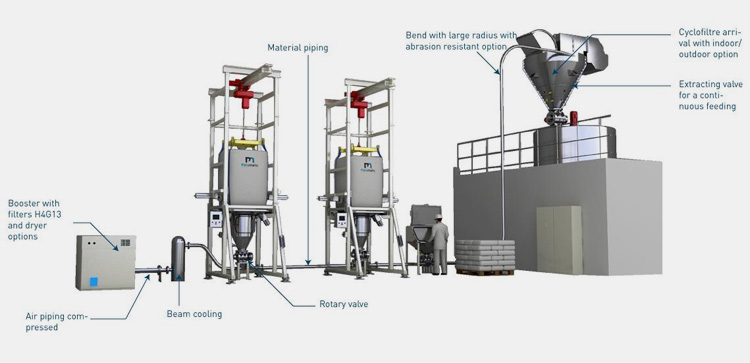

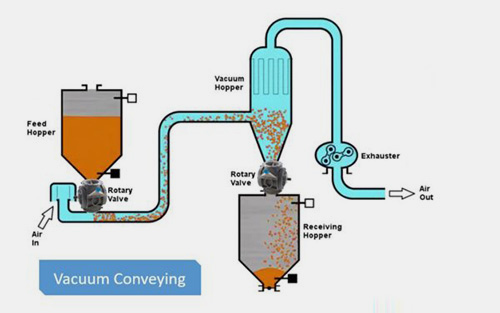

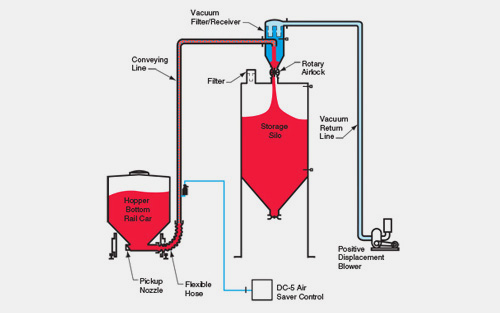

Dilute Phase Vacuum Feeding

Dilute phase feeding refers to the process of conveying particles by using high velocity and low pressure. The method of dilute phase is essentially continues due to which it is most commonly used. It needs relatively large amount of air to feed less amount of particles.

Working Principles

This method of vacuum conveying is very common and starts with the loading of powder. The powder is diluted in pipe line having low volume. The transported material looks like cloud due to high distance. After cleaning material, the vacuum feeder processes it and release for final discharge by opening the valve.

Components

The components of a dilute phase vacuum feeding machine includes pressure blowers, vacuum pump, rotary airlock valves, beam cooling, extracting valve, dust filter and bin vents, material piping, cyclone separators and storage vessel etc.

Types

Dilute phase feeding consists of two types; positive pressure feeding and negative pressure. Positive pressure operate above atmospheric pressure, having low cost and suitable for powders. Negative pressure process with air below atmospheric pressure, having high cost due to complex components and best for hazardous substances.

Advantages

This system of conveying is highly flexible and easily handle the processing of various material. It has simple operational system and is cost economical. Parts can be easily disassembled for cleaning.

Disadvantages

High velocity and air volume consume more power. Not suitable for abrasive material because the constant high speed transportation of these materials can cause pipe wear. Fragile or friable products may deformed or crushed during the process.

Application

Due to high air pressure this method is good for processing powders, non-fragile and hard products. Industries including cement, flour and chemical are taking the services of this machine.

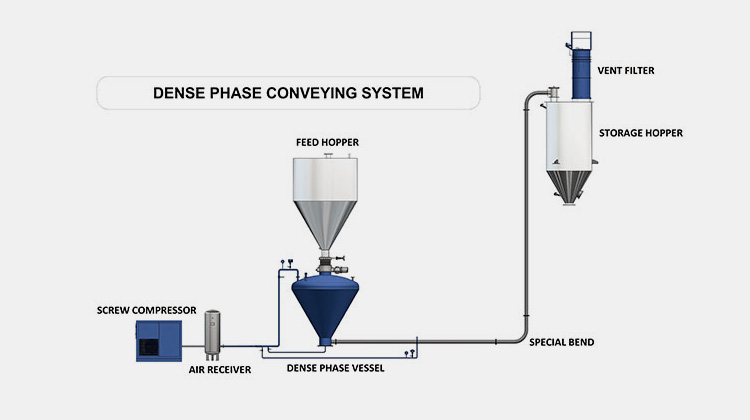

Dense Phase Vacuum Feeding

Dense phase vacuum conveying is the process where large amount of bulk material is processed using low velocity. This method is efficient as it take dense volume of particles. Its main principle is to slow down the velocity so as to avoid the stage where material may break or degrade.

Working Principles

The process initiates after switching the machine on. The air is entered into transport line where low power of air is required to process bulk material. Mostly, it is liquidized for continuous and smooth flow. The particles are filtered and delivered to containers below the hopper.

Components

It consists of supply vessel, motive gas device,line charger, clean gas piping, filter, inlet valve, vent valve, transporter and plant air supply.

Types

Types of dense phase feeding can be divided on the basis of their function like:

The first one is fluidized dense phase which prevent the spaces between particles and good for processing material like soap powder, fly ash, limestone etc. Another one is low velocity slug flow, it is good for friable granules such as sugar, wheat, milk powder and peanuts etc. Next is extrusion flow, which convey products with pipe full of material. For feeding meat lumps for canned animal food, chopped fish chunks and gravy etc.

Advantages

Due to low velocity it reduces the chances of material slip thus increase the level of efficiency. The particles do not abrade conveying and avoid wearing it. It consume less air, eventually would require small air-solid separation devices.

Disadvantages

Dense phase feeding system is more expensive compare to dilute phase feeding system due to its specs of components. To know the process of dense phase feeding certain level of qualification is required which make if difficult to operate the machine. Often, particles are liquidized for smooth flow but this causes mess as water goes down the line.

Application

There is no such limitation on the type of product that has to be processed by dense phase vacuum feeding. Instead, it can process multiple items like soft, hard and especially abrasive substances because of its high bulk density. Most of the nuclear industries, chemical, food and medical industries are looking for using this machine.

8.Differentiate Between Dilute Phase Vacuum Feeding And Dense Phase Vacuum Feeding?

| No | Factors | Dilute Phase Vacuum Feeding | Dense Phase Vacuum Feeding |

| 1 | Definition | In dilute phase feeding, particles are delivered with high air speed through continuous process | Where as a vacuum feeding machine conveys particles in batches with low air velocity it is called dense phase feeding system |

| 2 | Process | Its process is simple with loading material from feeding station in form of suspended particles | It is little bit difficult to operate and need proper expertise. However, it takes the material in bulk with low velocity |

| 3 | Speed | Its conveying power very fast but deliver less amount at a time | This process is gentle and slow in nature due to low air pressure but convey large amount of bulk material |

| 4 | Suitable Material | It can harm fragile items thus is only ideal for material with low density and hard structure | It is material friendly and never damages brittle materials |

| 5 | Abrasive Material | It can be dangerous to feed electrostatic material by dilute phase | It is suitable for processing abrasive material and do not create any electric charge |

| 6 | Capacity | Its capacity of conveying is extremely high and can reach up to 10TPH | Due to reduced air tension dense phase delivering capacity is lower than 10TPH |

| 7 | Cost | Construction of dilute phase feeder is typically less expensive due to light duty work | It is more expensive with heavy duty components |

| 8 | Example |  |

|

9.What Are The Common Problems And Troubleshooting Of A Vacuum Feeding Machine?

Vacuum feeding machine is highly effective equipment for transporting variety of materials. However, few problems may arise during the process which can be resolved by knowing underlying troubleshooting:

| No | Problem | Solution |

| 1 | Vacuum pump pressure is higher than normal and particles are escaping from line | There may be product build-up problem or leakage in elbow. Recover the coupling line and plugged convey lines |

| 2 | The filters and bin vents are fluctuating with inconsistent pulses | Bags are dirty or solenoid is bad. Replace inspecting filter bags and diaphragm |

| 3 | Sudden blockage in pipeline | It may be due to heavy load or low air pressure. Maintain the velocity of air and fix particular rate for feeding so that material can be easily passed through pipeline |

| 4 | Particle degradation problem occurs during feeding | Friction against pipeline can create break in friable material. To prevent this make sure that air pressure is low and use dense phase feeding for fragile items |

| 5 | Material become sticky and leads to condensation | The reason can be temperature change due to which particle absorb moisture. To solve this, trace the heating part and adjust proper air blowing |

10.What Should Be Considered Before Buying A Vacuum Feeding Machine?

While purchasing a vacuum feeding machine you must have to be vigilant enough and stay alert to consider some of the important aspects such as:

Nature of Products

What type of material you are assuming to feed either it is fragile or strong, free flowing or cohesive, these all questions matters a lot. Same as, for soft and easily broken material dense vacuum feeding machine is best suitable for retaining their sterility like that of medicines. While on other hand, for hard material dilute phase vacuum feeding machine is good.

Material of Construction

Before choosing any automation solution it is very important to know what its texture is tailored with whether stainless steel, carbon steel or pharmaceutical sanitary grade. By looking properly into it can relieve you in processing variety of materials due to higher degree of energy efficiency and solid build-up.

Machine Features

Do you know the features of vacuum feeder which you are considering to purchase it? Like what is its upstream process? Is it coming from hopper, feeder or reactor? The airflow direction and size of vent, fans, and filters these all can influence the feeding of your products so make sure they are ideally equipped and compatible to your needs.

Velocity of Feeding Rate

How much volume a vacuum feeding machine can deliver per hour is another crucial factor to know. So make sure that its rate of conveying is up to the mark.

Type of Process

Usually, feeders are of two types; volumetric and gravimetric. Volumetric feeders process material in batches without exact measurement and are less expensive. If you just want to feed the products this is better applicable. While as, items which requires high accuracy level with continuous processing are in need of gravimetric feeders.

Headroom above Process Equipment

Find out how much headroom is available in machine. It is the compulsory space for processing because even smaller vacuum feeders require at lead 30″ headroom.

Conclusion

A vacuum feeding machine has brought automation in feeding industry due which it has been recognized globally with super-fast and safe performance. Allpack is the leading supplier of vacuum feeding technology for more many years. If you are eager to know more about this machine, feel free to ask.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide