Your Ideal Vertical Packaging Machine Manufacturer

- PLC Type Control System

- Wide Range Of Application

- Servo Motor Film Driving System

Vertical Packaging Machine

Allpack vertical packaging machine can finish the process like conveying bag,bag making,filling,weighing,sealing,cutting,counting, etc.It has bilingual touch screen and stainless steel cabinet, which make it easy to use and durable.Set up the required data in the visuable settings,the control system can optimize matching with all the program so that it can achieve the best packing speed precisely.The vertical packaging machine also has color system controller so that it can get the complete trade mark design.It is suitable for the complex film and tin foil and other packing material.Allpack vertical packaging machine has excellent packaging effect,low noise,clear sealing texture and strong sealing performance. These machines are ideal equipment for food, beverage, pharmaceutical, commodity, agriculture and chemical industries, etc.

The Buyer's Guide

Vertical Packaging Machine: The Complete FAQ Guide In 2025

Global manufacturers with packaging processes are focused in producing highly precise and presentable products. This not only increases the life of product but also attracts the customer towards it.

Vertical packaging machines are also one of the finest machines that meet high volume of packaging production line and produces perfect result. Selecting a perfect machine for production setups is always a difficult task so for this we Allpack China are providing you this buying guide for your better understanding and assistance. So enjoy the guide and take the most of it!!

1.What Is A Vertical Packaging Machine?

A vertical packaging machine is an advanced packaging machine that is used to pack both food and nonfood products. The machines are now used almost in all types of industries depending upon the mode of application. Food, beverages, medicines, cosmetics, chemical, agricultural and pharmaceutical industries use vertical packaging machine due to its high productivity and precise packaging.

2.What Are The Features Of A Vertical Packaging Machine?

Some of the features of a vertical packaging machine are

Packaging Products

Products like seeds, nuts, granular, liquids, containers, paste, oil powders, beverages, medicines and others can easily be packed using a vertical packaging machine. Numbers of products are easily packed without any material deformation or destruction like traditional methods.

Economical Packaging

Automatic vertical packaging machines produce a large number of products in no time that makes the manufacturer to earn more profit in less time. Machines are highly economical according to the production they deliver.

Machine Structure

Vertical packaging machines are mostly present in compact sizes and are made up of stainless steel. This helps in moving the machine anywhere and also prevents it from humidity. The components of a vertical packaging machine are also available easily that help in reducing machine downtime.

Packaging Material

Mostly polyethylene, polyvinyl chloride and polypropylene materials are used in packaging processes which are easily available in any part of world. No such special type of material is required for packaging of materials/

Machine Compatibility

Every type, size, weight and shape of bag, pouch or envelope can be packed using a vertical packaging machine. This makes it stand out in its performance and blocks the usage extra machine for separate tasks.

Fine Edge Cutting

Filling material when filled in the film are present in continuous roll. The machine only separates product with each other. In this regard, sharp and fine edge cutters are present at the end on vertical packaging machine. These sharp edge cutters are present in vertical packaging machine cut the product and separate them from each other. The cutters are mostly made up of stainless steel and iron material.

3.What Types Of Products Are Packed In A Vertical Packaging Machine?

Vertical packaging machine are suitable for every type of product either it is liquid or solid. The filling process allows packaging of number of materials in a single vertical packaging machine. It only depends on the nature of material and according to that the speed and filling process is maintained. Some of the products that are packed using a vertical packaging machine are

From different filling materials forms , there are:

Powder

Products like flour, coffee, cocoa powder and etc. are prepared in a vertical packaging machine.

Paste

Jelly, toothpaste, color paste and others are packed in vertical packaging machine.

Liquid

Example of liquid products is milk, liquid chemical, beverages and etc.

Granular

Nuts, snow, coal and etc. are the granular products that are packed in vertical packaging machine.

From different applying industries, there are :

Food Materials

Vinegar, salt, rice, sugar are sealed and packed in vertical packaging machine.

ChemicalMaterials

Chemical industry packs paint, zinc, bleach and etc. in plastic films.

PharmaceuticalMaterials

Tablets, vitamins, capsules, syrup and etc. are the example of pharmaceutical materials.

AgriculturalMaterials

Bean, fertilizer powder and pesticides are the example of agricultural products.

4.What Are The Applications Of A Vertical Packaging Machine?

There are several industrial applications of a vertical packaging machine, and all depends on the method that how packaging is done. Material compatibility is also an important factor to check its applications. Some of them are

Food Industry

Daily using items that fall in the category of food industry high level of customized packaging. This is due to an increasing market competition and shifting of customers. Vertical packaging machines are best suitable for such type of industry as it can pack powder, granular, solids and liquids material in bags, pouches, strips etc.

Cosmetic Industry

Chemical industry is also one of the leading sectors where vertical packaging machines are used to pack products like lotions, creams, serums, and shampoos. Highly efficient packaging of these materials is carried out in bags or pouches to prevent it from contamination. High productivity is also a reason to use vertical packaging machine is cosmetic industry.

Pharmaceutical Industry

Drugs, medicines in both powdered and solid form are packed using a vertical packaging machine. As medicines are directly associated with human life so it requires high care and sensitive handling. A vertical packaging machine offer hard coat packaging to prevent entrance of environmental objects. Also a vertical packaging machine produces medicines in large quantity to meet the global requirement.

Chemical Industry

Another industry where frequent usage of vertical packaging machine is found is chemical industry. Number of chemically filled pouches and bags are produced by these machines. As the exposure of these chemicals can be vulnerable for the environmental conditions this is the reason vertical packaging machines are used to provide safe packaging.

Agricultural Industry

Agricultural industry also applies usage of vertical packaging machines to enhance their product packaging and to keep the environment secure from fertilizer products. Machines are highly effective when it comes for packaging of fertilizers, seeds and beans.

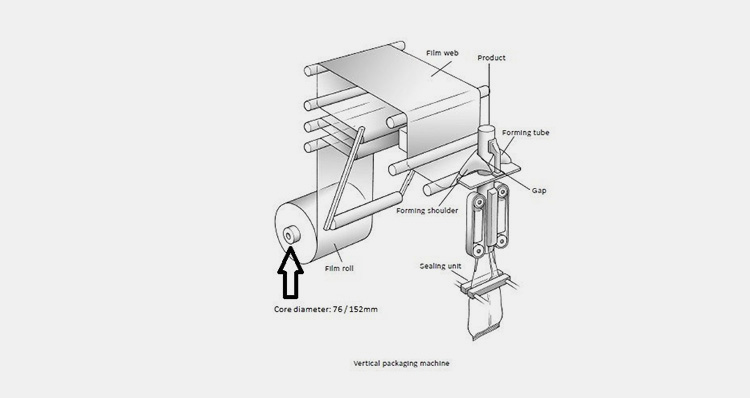

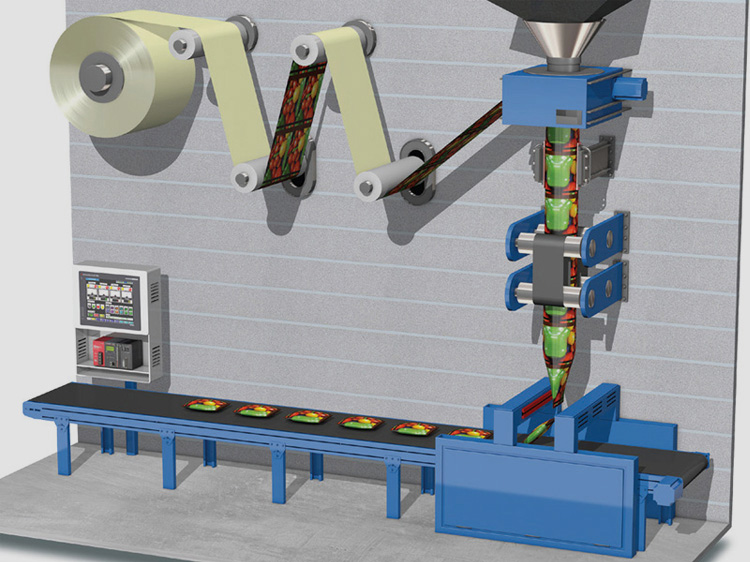

5.What Are The Working Principles Of A Vertical Packaging Machine?

A vertical packaging machine follows simple operational procedure. The machine works in following ways

- Initially a film container which is the most important part of a vertical packaging machine is positioned in a way that it gets support with the mixing rod.

- Film from a tube shaped segment moves towards the heating device vertically where the bags are made in a transverse heat sealing instrument.

- The filling materials are filled in these bags through the filling pipe and are proceeded towards the heat packaging device.

- Here the sealer of bags is done from all edges and finally cut off to produce the end product.

6.What Are The Advantages Of A Vertical Packaging Machine?

When it comes to effective and efficient packaging of products; vertical packaging machines are considered to be the best among those. Manufacturers are now focused in installation of vertical packaging machine in their production setups because of its numerous benefits. Some of those are

Cost Effective

The buying cost of vertical packaging machine when compared with the production speed and machine life makes it highly cost efficient. Large production setups can be achieved using these machines.

High Production Speed

All types of vertical packaging machines either manual or automatic have high production speed and are suitable for respected industries accordingly. Product range lies in between 20 to 100 that are packed using a vertical packaging machine in a minute.

Automated Systems

A single controlled computerized system is incorporated in a vertical packaging machine which makes it highly versatile and reduces human errors. There are always less chances of accidents, injuries and damages in an automated vertical packaging machine.

Long Shelf Life

The structure of machine is made up of stainless steel which makes it able to resists from moisture, rust and humidity.

One the other hand effective sealing and packaging also ensure product safety for a longer period of time and saves it from contamination.

Multi Purpose Processes

A single vertical packaging machine performs each task in it from weighing, filling, sealing and packaging. This makes it able to perform multi tasks within a single machine. Also the ability to perform packaging of different sizes of products is one of the unique advantages that can be gained from it.

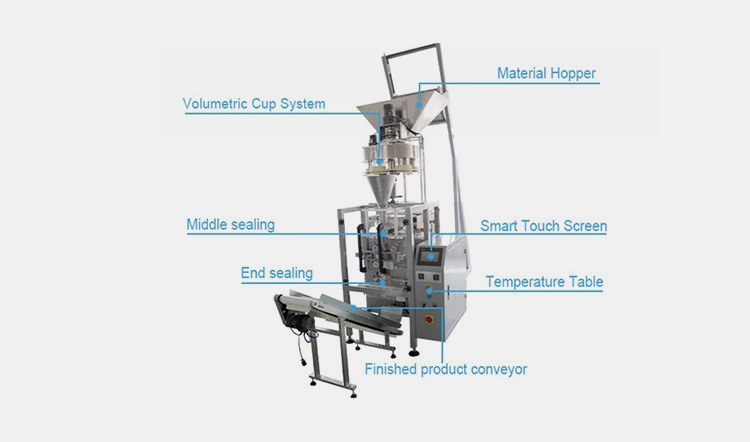

7.What Are The Main Components Of A Vertical Packaging Machine?

Likewise the working procedure of a vertical packaging machine, it also has few components in it depending upon the level of automation and productivity of any industry. The machine is divided into three main parts supported with auxiliary parts that are responsible in performing the operation of a vertical packaging machine. The main parts of a vertical packaging machine are

The Blanking Part

The blanking part is the important one where the material is mixed and filled into the bags afterwards. Here the material hopper, volumetric weighing cup, liquid pump, screw weighting and combined weight system is present. The filling material travels through all these segments before the packaging process.

The Film Release Part

The initial part of a vertical packaging machine is its film releasing part. In this part the film roller is installed and released towards with high precision. Tensioners and unwinding rolls are present with driving motors that allows the smooth flow of film into the system.

The Packaging Part

In the last part of machine packaging unit is present which comprises of sealer, cutter and laser inkjet. Here the final packaging is performed after the material is filled in the bags or pouches.

8.What Types Of Vertical Packaging Machine Are There?

Types of vertical packaging machines are classified according to the machine automation, packaging method, material and mechanical structure. The types of vertical packaging machine according to its classifications are

According to Machine Automation

Semi-Automatic Vertical Packaging Machine

A semi-automatic vertical packaging machine involves both manual and automatic operations. Filling of material is done by the operator and also he is responsible for placement of bags or pouches. Filling and sealing process is done by machine. These machines are ideal for small and medium scale industries where average speed in productivity is required. Machine can be placed anywhere and are highly durable.

Fully Automatic Vertical Packaging Machine

The third type of vertical packaging machine with respect to automation is a fully automatic vertical packaging machine. Here all the processes from feeding of film roll and material to final packaging, all are performed by the machine itself. No human interface is required during the operation of a fully automatic vertical packaging machine. A large scale industry where the production volume is too high uses a fully automatic vertical packaging machine.

According to Machine Mechanical Structure

Continuous Vertical Packaging Machine

The pitch of film feeding unit is followed properly in a continuous vertical packaging machine and it does not breaks the pitch during any instance of operation. The machine maintains its pitch by forming upward and downward movement of sealing unit and inserts uniform material in it. High speed and efficient packaging is achieved by this type of machine.

Intermittent Vertical Packaging Machine

The process in this of packaging machine is terminated in between when the top and bottom side of the bag or pouch gets sealed. The machines separately seal both sides and due to this the feeding of film roll gets effected. Intermittent vertical packaging machine is not suitable for industries where high speed production is requires. They are ideal for low and medium level manufacturing plants.

According to Filling Material

Powder Vertical Packaging Machine

The powder formed material is filled and packed in a particular type of vertical packaging machine that is called as powder vertical packaging machine. The machine can easily pack different types of powders in a single bag and are highly efficient in multitasking. A production of 20 to 100 bags in a minute can be achieved by powder vertical packaging machine.

Paste Vertical Packaging Machine

Paste materials mostly present in chemical and medical industries are packed using a paste vertical packaging machine. These machines are suitable of medium scale industries where the production requirements lie in between 10 to 60 tubes per minute. But weight of the product should remain under 1 kg when it comes to the packaging of paste material.

Granule Vertical Packaging Machine

Granular material is sealed and packed with the help of granule vertical packaging machine. As heavy weight granules are difficult to pack by using traditional machines. Material is filled in the hopper lid and then passed to the system. 25 to 80 bags of granular can be packed using a granular vertical packaging machine.

Liquid Vertical Packaging Machine

Another type of vertical packaging machine is liquid vertical packaging machine that packs material that is liquid in nature. 10 to 30 bags of weight around 500 kg are packed using this type of machine. Chemical, food, pharmaceutical and agricultural liquid materials are ideally packed using a liquid vertical packaging machine.

9.What Are The Differences Between A Vertical And A Horizontal Packaging Machine?

Both types of packaging machines either vertical or horizontal are used for common purpose. The movement of packaging material in the system is one of the major differences in both type of packaging machines. The areas where both the machines are distinguished are

Working Method

The most common differences in both type of packaging machines is in there working methods. In a vertical packaging machine the film roll is fed over a plough with a much greater force due to the structure of machine.

Whereas in a horizontal packaging machine the same film rolled is in series with the system. This is why the roll is pulled through the machine with much minimum force and effort. This also allows less material damage in a horizontal packaging machine.

Packaging Products

The second difference in between a vertical and a horizontal packaging machine is the filling of packaging product. In a vertical packaging machine the bag or pouch is hold from its two sides whereas all the remaining sides remain closed. This blocks 100% filling of material and leaves small spaces in the bag.

In a horizontal packaging machine, all the sides are closed and only the filling side remains open. Due to this complete 100% space of the bag gets utilized and no vacant spaces are left. Horizontal packaging machine in this regard is more efficient as compare to vertical one.

Filling Process

A vertical packaging machine only seals and packs the material in its initial stage. Re heating, cooling and heating processes are carried in a single cycle in further steps.

Whereas in a horizontal packaging machine; all the processes are aligned in a single line. Initially the sealing is followed by the packaging process and the preheating, heating and cooling cycles are performed separately in different steps.

Automation

Both the machines are available in all manual, semi-automatic and fully automatic types and are used according to their application.

10.What Are The Common Errors That Are Faced In A Vertical Packaging Machine And How Are They Rectified?

Some of the problems that occur in vertical packaging machines and their remedies are

| S.NO | Problem | Cause | Remedy |

| 1 | Abnormal Sealing | Hugh pressure of sealing | Maintain the pressure according to the standards |

| 2 | Uneven sealing of product | Misalignment of guide | Adjust the guides according to the standard |

| 3 | Knocking and abnormal sound | An equipment within the machine may be broken | Replace the equipment with a newer one |

| 4 | No proper power supply | Breaking of electric wires or connectors | Repair the area where the wire is found broken |

| 5 | Machine cycles stops suddenly | Burnt of fuse | Check the fuse and replace it. |

| 6 | Poor edge cutting | Damaging of knives blades or cutters | Replace the damaged knife with new one |

11.What Common Factors Should Be Considered Before Purchasing A Vertical Packaging Machine?

Some of the important factors that should be considered before purchasing a vertical packaging machine are

Machine Quality

Where numbers of manufacturers are busy in making vertical packaging machine, some of those are not reliable. They quality of packaging provided by every type of vertical packaging machine cannot be ideal so it is necessary to select the machine which provides fine edge cut, high quality and pure packaging of products..

Right Type of Machine

Another important factor while selecting a vertical packaging machine is that the machine should be selected according to the material that is to be filled in it. The buyer should closely monitor its production requirement and then select the right type of machine. Liquid one can never be compatible with a solid or granular vertical packaging machine.

Material of Structure

The structure of machine is also a deep concern. A machine made up of stainless steel is always considered to be the most suitable one. Stainless material resists rusting in machine and increases the life of both machine and material.

Productivity

The buyer should go through its production requirements with a forecasting of 5 to 10 years because it has to be a bigger investment which has to be made with deep concern.

Conclusion

Vertical packaging machines are used in different industries according to their application. It is always necessary to get all machine related information before going to purchase it. In this regards, we Allpackchina are providing you this buying guide that will assist you in purchasing a right type of vertical packaging machine according to your production setup. If you still find any query related to it contact us 24/7 or visit our website http://www.allpackchina.com/ .

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586