Your Ideal Softgel Encapsulation Machine Manufacturer

- High-speed Disintegration

- Advanced Water Cooling System

- Automatic Control Technology

Softgel Encapsulation Machine

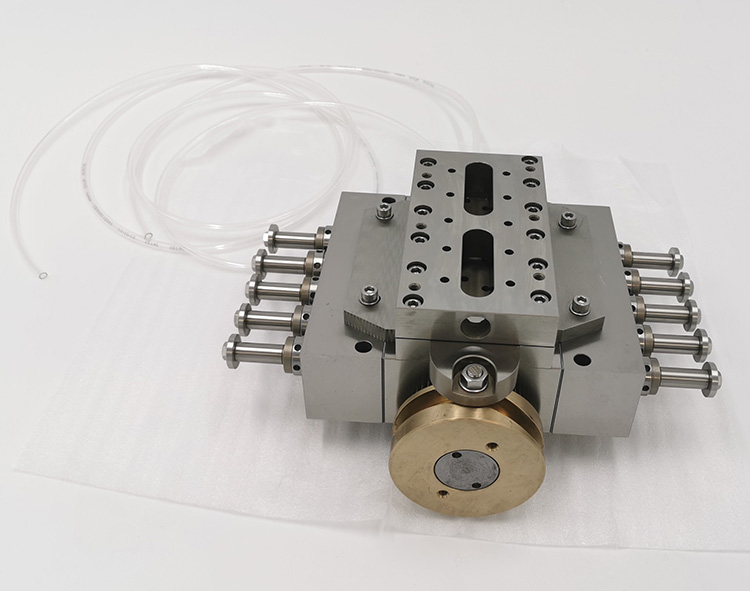

Allpack softgel encapsulation machine is mainly used for laboratory and research institutions capsule drug product development trial, may be used as pharmaceutical, health care products factory, food factory test equipment, aircraft using a variety of automatic control technology, simple operation, function stable and reliable; Machine meet GMP standards, models small, functional, superior performance, compact structure.It consists of main machine, gelatin melting tank, insulated gelatin storage tank, electric control cabinet, conveyor, shape/drying rotary cage, colloid mill etc. The working principles: put the oil, gelatin-insoluble liquid, paste, plaster (e.g. extract plaster) inject into between two gelatin skin quantificational, through the two roller dies and press and cutting into various shape soft capsules, such as egg shape, fish shape, cylinder, ball shape, calabash shape.

Softgel Encapsulation Machine

HTSYS-5 Softgel Encapsulation Machine

Allpack HTSYS-5 Softgel Encapsulation Machine is mainly used for laboratory and research institutions capsule drug product development trial, may be used as pharmaceutical, health care products factory, food factory test equipment, aircraft using a variety of automatic control technology, simple operation, function stable and reliable; Machine meet GMP standards, models small, functional, superior performance, compact structure.Cold system with integrated cooling fan, low energy consumption, convenient installation, the temperature accuracy.

Compact structure&easy operation

Simple maintenance&stable performance

High production and low consumption

RJN Series Softgel Making Machine

Allpack RJN series softgel making machine is widely used in pharmaceutical, cosmetic, health food and pesticide etc, such as egg shape, fish shape, cylinder, ball shape, calabash shape.It consists of main machine, gelatin melting tank, insulated gelatin storage tank, electric control cabinet, conveyor, shape/drying rotary cage, colloid mill etc.Adopting air pressure ensure gelatin storage tank conveys gelatin on the ground, ensure better production environment.The capsule conveyance belt adopt food-grade conveyance belt which is non-toxic, non-sticky, and easy to wash.

Automatic gelatin supply and feeding system

No dead corner&easy to clean

No oil dropping

TM-100 200 250 Series Automatic Softgel Making Machine

Allpack TM-100 200 250 series automatic softgel making machine is the essence condensing of decades professional experience on softgel. During the development process, the designer personallly conducted long-term production investigation and research in the softgel production base, combined the characteristics of various types of softgel machines, absorbed rationalization suggestions from operators and verifying by improved experiments, adopted international advanced control technology.

Full-automatic gelatin melting and material supply system

Vacuum stirring system

Automatic weighing of main material

ZTHT-100 Softgel Encapsulation Machine

Allpack ZTHT-100 softgel encapsulation machine can quantificationally inject the oil, mixing suspenion and pasty mass into the capsule to form all kinds of softgel encapsulation with different size, shape and color. Because of the merits of high speed disintegration, easy to oral, hard to oxygenation, easy to store and take, this softgel encapsulation machine is welcomed by more and more customers. Owing to the high productivity, charging exactly, quality stabilization, high finished product rate.

Strong production capacity

Advanced water cooling system

Capsule package rate is up to 98%

ZTHT-125 Softgel Encapsulation Machine

Allpack ZTHT-125 softgel encapsuleation machine is designed to produce softgels from either animal gelatin or plant starch(tapioca).It is an expert in the soft gel encapsulation machine manufacturing. All machines come in both standard and custom designs for various soft gelatin capsule filling needs in pharmaceutical, chemical and food processing industries.Softgels are very popular especially in the fast-growing nutriceutical industry, take this chance to skyrocket your business.

Customized Shape and Size

High-efficiency

Suitable for various liquids

ZTHT-125B Softgel Encapsulation Machine

Allpack ZTHT-125B softgel encapsulation machine adopts large-size touch screen and has fault diagnosis function, which can store various operating parameters and reserve network interface.The mold adopts aviation aluminum alloy and has a long service life. Optimized design, the number of cavities is large, and the mesh adhesive rate is low.The rubber skin cooling adopts the independent split professional chiller, which has low energy consumption and high cooling efficiency.

Adopt parallel design& high stability

Independent variable frequency drive motor

High assembly accuracy

ZTHT-200 Softgel Encapsulation Machine

Allpack ZTHT-200 softgel encapsulation machine ,the whole machine adopts optimal design, full-featured, compact structure. The equipment package includes a host computer and control system, a dryer, a plastic tank, a mold and a movable platform, small footprint package of equipment, applicable to a variety of industries such as medicine, food, cosmetics, health care products. This softgle-making machine aircraft uses a variety of automatic control technology, simple operation, stable performance, reliable work.

Same mould of big production machine

High accuracy and easy operation

Occupies small space

The Buyer's Guide

Softgel Encapsulation Machine: The Complete Buying Guide In 2025

Vitamins and nutritional supplements are the essential source for maintaining healthy life due to which we take them as per our daily requirements. Mostly, these elements are combined together in form of softgel capsules.

Do you have any idea about how the process of softgel capsulation occurs? Are you also engaged in the manufacturing of softgel capsulation? Or do you desire to bring this advance technology of softgel encapsulation in your production line? If Agree! Then this article is designed for providing you the knowledge, you are constantly looking for. Just stay here and keep reading all the questions to know about the softgel encapsulation machine, its uses, classification, application and many more!

1.What Is A Softgel Encapsulation Machine?

Softgel encapsulation machine is a mechanical device employed to make softgel capsules by filling semi-solid, liquid or suspension into hermetically sealed gelatin. The process of filling these substances into pre-made gelatin shells is what we called encapsulation. Moreover, it enhances the level of accuracy for your capsules and is capable of processing different types of capsules with varying shapes, sizes and colors.

This machine uses a unique method for encapsulation due to which various industrial sectors are admiring its performance including pharmaceutical, nutraceutical and cosmetic industries etc.

2.Why Should You Use A Softgel Encapsulation Machine?

There are many reasons which would compel you to go for a softgel encapsulation machine if you are engaged in some tasks of preparing medicines or capsules. These reasons are highlighted below:

Strong Production Capacity

This machine comes with certain qualities among which the most prominent and usable is high production capacity because it is the factor every industry looks for. It can work for 24 hours/day and 300 days/year with non-stop process. In addition, its packaging rate is about 98% which is greater than enough.

Robust Construction

This equipment is 100% made with stainless steel and aviation alloy creating strong construction due to which it work as a protective and an anti-acidic agent against bacteria.

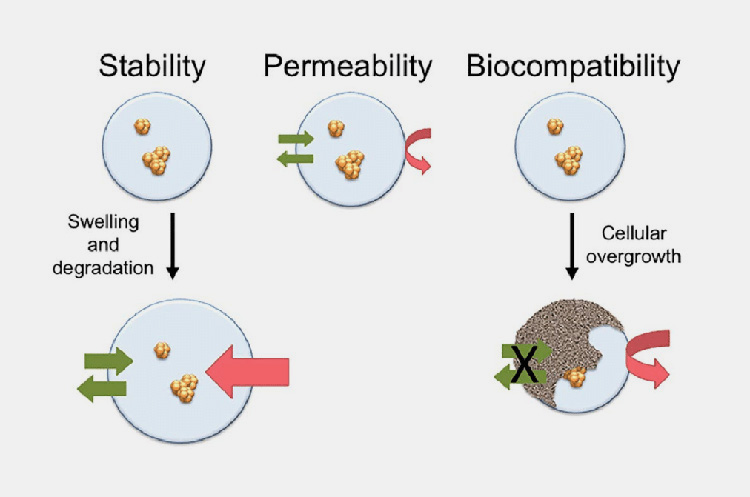

Stability

High quality components and advance assembly techniques make a whole application complying international standards. Eventually, it assures a stabilized performance with formation of beautiful shape pills. These softgel capsules easily get soak up and have fast effects.

Reduce Labor Cost

Integrated with fully automatic system, this device is self reliant, does not need any labor for administering the entire mechanism instead carry the process smoothly.

Hygienic

It delivers highly pure substances into softgel capsules and protects them from external chemicals and physical reactions.

Nature Of Capsules

Softgel capsule is a type of pill preferred by most of the people due to their attractive appearance, shape and easy swallowing. It provides quick absorption as a result of which the need for such capsules is increasing and to cope with this, no other solution is better than incorporating softgel encapsulation machine into production line.

Sustain Uniformity

Filling small amount of active ingredients into capsules is a challenging job. However, a softgel encapsulation machine performs this task accurately by dispensing the exact dosage of substances into gelatin shells.

3.How A Softgel Encapsulation Machine Can Be Operated?

To fully understand the working procedure of a softgel encapsulation machine you should have proper knowledge of the each step we have elaborated below in detail. These steps include:

Gelatin Preparation

The very first step involve in this process is the formulation of outer shell. This outer shell is also known as gelatin that is obtained from animal sources like bones and skin. Other items such as colorants and opacifiers are also added to get the desired shell. Gelatin is prepared in melting tank through heat after which the liquid syrup (gelatin) is delivered to spreader box, cooling drum and die roller sequentially.

Preparation of Filling Material

It is the second stage where preparation of filling material is occurred. Depending upon the requirements of your desired content that may be in form of liquid, semi-liquid, oil, or paste-like substances are poured into hopper. These ingredients are well mixed by processing tanks, mixers or mills. After getting prepared, the solution flows from hopper to the injection wedge via tube.

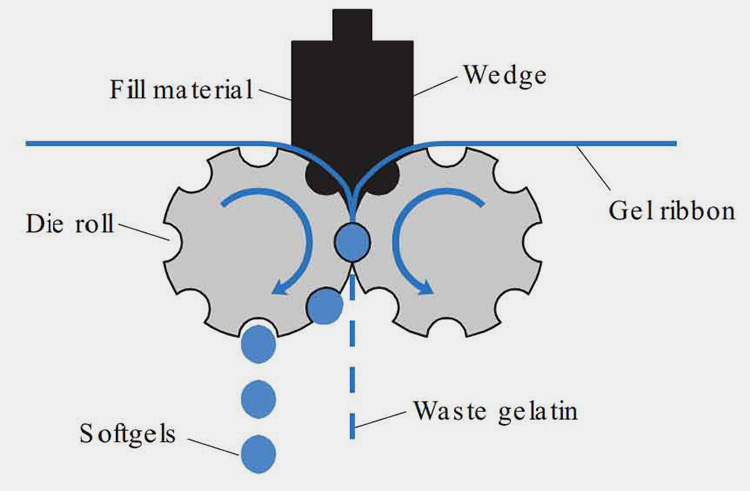

Encapsulation Process

In third stage machine combines together the gelatin and filling material to create softgel capsules. Two layers of gelatin are moved into die rollers from dual sides. While as filling material is dispensed into these shells from upper side via injection wedge and capsules are tightly sealed. Here the process of encapsulation finally happens and softgel capsules exit from machine through discharge chute.

Drying and Inspection

The fourth and final stage is where these ready softgel capsules are processed by the tumbler dryer with the help of conveyor belt. Now, when these capsules are passed through every essential step, an inspection device accurately assess the capsules and remove inaccurate ones in order to provide you with the capsules having right quality standards.

4.In Which Areas Does A Softgel Encapsulation Machine Is Frequently Utilitized?

Softgel encapsulation machine is an integral part of any firm that is associated with the production of supplements or vitamins in form of softgel capsules. Its area of applicability is far broader which can be understood by looking into the following details

Pharmaceutical industry

The first and foremost industry which comes in our mind when looking for applications of a softgel encapsulation machine is pharmaceutical industry. The reason behind is that most of the people around world are facing difficulty in swallowing tablets especially children and old people. To counter this obstacle softgel capsules are warmly welcomed as they are easy to swallow and are often tasteless.

Nutraceutical Industry

Nutraceutical is a broad term that carries essential areas under its umbrella. Softgel capsules which are made up of natural food products or herbal material can be labeled as nutraceutical pills. These additives have essential role in improving health, prevent chronic diseases and reduce the risk of various dangerous disorders. Some of the softgel capsules that come under the category of nutraceutcal are fish oil softgel capsules, plant based sofgel capsules etc. All of these capsules are prepared by a softgel encapsulation machine.

Veterinary Industry

The prime objective of any veterinary industry is to provide medical, dental and surgical treatment to animals in order to cure their injuries and also provide them with additional supplements. However, sometimes it gets difficult to administer animals and force them to take medicines. At that time, a dosage in form of softgel capsules would be a good choice as it can be given easily through many ways.

Food Industry

Among various other sectors, food industries are also making use of this equipment for producing gelatin candies and chocolate beans etc.

Cosmetic Industry

When we talk about the importance of softgel encapsulation machine we cannot neglect the essential role it plays in cosmetic area. Now a day, people are more inclined towards caring for their skin, taking hair treatments, remove dark circles and reduce the appearance of wrinkles. For these purposes, numerous nutrients and vitamins are compiled in form of softgel capsules which are clinically proven. For example, ceramide and collagen peptide softgel capsules are used for glowing skin.

Research Laboratories

Research laboratories are the experimental platforms where different sort of experimentations are conducted to make new discoveries regarding medicines and find cures to counter various health diseases. Thus, complete machinery is the prerequisite of these research laboratories for the accomplishment of their tasks.

Healthcare industry

Healthcare industries are working around the globe both on national and international level like World Health Organization. Most of these countries have launched free medication camps for their citizens which encompasses preventive, rehabilitative and curative care. The only reason is to ensure full healthcare support for which they also take the services of a softgel encapsulation machine.

Paintball industry

Paintball is a hardware industry which is engaged in producing softgel balls with multi colors liquid inside. These paintballs are used for recreational activities and mostly available in amusement parks or other similar platforms. The manufacturing process of these balls is similar to that of softgel capsules due to which these industries are constantly admiring the use of a softgel encapsulation machine.

Vegetarian Softgel Industry

Vegetarian softgel industry is the area where only plant based softgel capsules are produced for customers who do not want to consume the capsules containing animal sources. These softgel capsules are prepared from pure vegetable sources like starch, cellulose and pullulan through softgel encapsulation machine.

5.What Are The Differences Between Softgel Capsules And Hardgel Capsules?

How softgel capsules can be distinguished from hardgel capsules is elaborated as under:

| No | Factors | Softgel Capsules | Hardgel Capsules |

| 1 |

Product Nature |

Softgel capsule is an oral dosage of medicine with softgel cover containing active liquid ingredients inside. | Hardgel capsule is a type of pill with hard cover carrying dry powder or small pellets. |

| 2 | Machine Requirement | The entire process of making softgel capsules is performed by a single machine. | They require two machines, one for making hard shell and other for filling material. |

| 3 | Dissolution Strength | Softgel capsules rapidly dissolved in gastric juice and carry out their function quickly as compared to hardgel capsules. | Hardgel capsules take long time for absorption and cannot easily dissolve as a result it is slow in performing its functions. |

| 4 | Parts | They consist of only one piece which is tightly sealed. | They contain two parts which can be separated. |

| 5 | Shape | Softgel capsules are mostly tabular, oval and round in shape. | Hardgel capsules have only one shape that is cylindrical. |

| 6 | Example |  |

|

6.Describe The Structure Of A Softgel Encapsulation Machine?

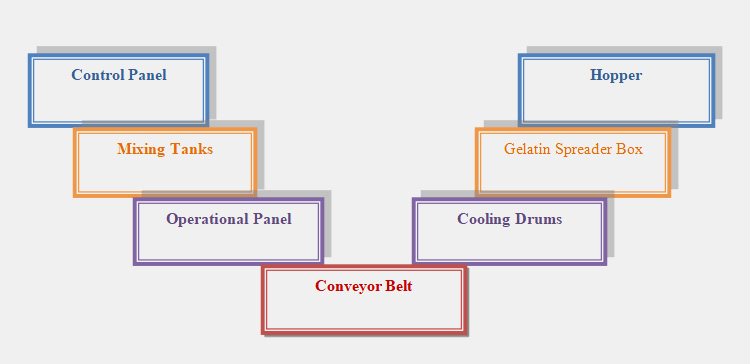

A softgel encapsulation is the combination of various parts which result in the formation of a compact machinery. These parts are separately described below in detail.

Hopper

This is the part of machine in which the filling material is loaded that has to be delivered to machine. The hopper has capacity of holding round about 5 kilogram of capsule material. Although, too small quantity can cause the equipment to plunge blankly and heavy load can lead to tube blockage. Due to this reason, 60-80 mesh is marked suitable filtering size.

Operational Panel

The touch screen or PLC control system has now been introduced around the world. This device contains all the parameters required for operating a machine which are further modified by an operator as per product demand. Integration of this part into a softgel encapsulation machine indicates the degree of automation it possesses and provides you to set the speed, temperature and filling rate etc.

Wedge

Wedge is a device with narrow mouth that is placed under the hopper and above the die rollers. Through wedge needle filling material is directly conveyed to the ribbons.

Gelatin Melting and Mixing Tank

This is the place where gelatin or shells for soft gel capsules are prepared after mixing and melting. It consists of steel valves, clamps breather with triple wall jacket. This tank is of stainless steel and comes with different capacities depending upon the type of machine.

Gelatin Spreader Boxe

It is the most essential component of the machine, where melted gelatin is stored and the thickness of shells can be also determined in this place. After setting, gelatin is spread by this part on cooling drums in accordance with required thickness.

Softgel Die Roll

This is the vital part of a softgel encapsulation machine that influences the quality and appearance of capsules by determining their shape, cutting and sealing. There are blank areas around die rollers which make holes when these rollers join together by their ends. The shape of holes is taken by the capsules after they get passed through these holes.

Cooling Drums

It is also known as gelatin ribbon drums which it utilized to spread the melted gelatin in order to transform it into thick film of gelatin.

Conveyor

It works as a delivery system and take the prepared capsules from machine to discharge chute ultimately load them towards dryer or inspection machine. It walks back and forth as directed by the control system.

7.Explain The Major Classification Of A Softgel Encapsulation Machine?

A softgel encapsulation machine is the result of high degree of automation that’s why it cannot be found in semi automatic or manual form rather it can be classified on the basis of its capacity. These types are displayed below:

Small-scale Softgel Encapsulation Machine

This type of machine is having small capacity of producing softgel capsules. It is fully automatic with robust construction that gives you full result. In addition, it has precise footprint as compared to other types of machines under same category. Consequently, it requires less space and is easy to handle.

Working Principles

The process is easy, as small amount of material has to be processed. Gelatin material is put into gelatin tank while capsule filling material into separate tank. After melting, gelatin is delivered to spreader box and dispensed over the cooling drums. On the other side, filling material is conveyed to tube for entering into the die roll. A time comes when two ribbons made of gelatin enter into die rollers from opposite position and filling material is transferred into these ribbons from the upper side via tube. Hence, the softgel capsules are prepared here.

Components

It comprised of similar parts which other types of softgel encapsulation machines contain but it does not have additional parts connected. For instance machine hopper, cooling drums, rolling dies, gelatin preparing tank, filling solution tank, control system conveyor belt, tumbler dryer, gel box and discharge chute etc

Application

It is mostly used in small production areas like that of laboratories and research institutions etc.

Medium-scale Softgel Encapsulation Machine

This machine is capable of producing capsules of medium size unit with moderate power consumption. This is most suitable for average production volume and can be attached to some auxiliary devices.

Working Principles

Material for preparing gelatin and capsules are poured into their relevant tanks. After passing through initial stage, melted gelatin is turned into semi-solid shells and filling material is prepared. Once they get prepared, both are following their ways and unite together in die rollers in form of softgel capsules. These capsules are then processed through tumbler dryer as a final outlet.

Components

This machine has few additional components so as to make the process more efficient. These parts include hopper, machine frame, softgel die roll, electric power system, cooling drums, conveyor belt, fan blower, gelatin mixing tank, medicine mixing tank, gel box, wedge, air compressor, cooling drums and dryers etc.

Application

This is an ideal solution for research platforms and other medium size sectors like health sector, pharmaceutical, herbal and food Industries markets.

Large-scale Softgel Encapsulation Machine

As the name indicates, this type of machine has extremely large capacity of processing huge amount of softgel capsules in each hour. You can constantly operate it for 24 hours without any disruption. Thus, it is preferred to run large manufacturing spheres.

Working Principles

Due to the involvement of many components, procedure of this machine is lengthy but efficient. Liquid necessary for preparing gelatin is put into heated tank for producing shells and medicinal items are put into hopper consists of mixing system. Gelatin material is delivered to spreader box and released over the rolling drums which cool down the melted gelatin. Inner material of capsules is directly transferred to die roller sequentially after the double ribbons are placed in the die cavity. Liquid solution gradually falls inside these ribbons resulting in the formation of softgel capsules after which they are discharged by chute. Additional process occurs here when these capsules are dried, polished, inspected and eventually filtered into purified form.

Components

This machine is integrated with many auxiliary devices which contribute in enhancing its performance. These parts consist of heating system (medicine hopper, gel box and wedge), gelatin mixing and filling material mixing tanks, conveyor, tumble dryer, electric cabinet, control panel, softgel sorting machine, lubrication system, softgel polisher, softgel pulverizer, inspection machine, air compressor, water chiller, rolling dies, cooling drums and tube etc.

Application

This machine has higher demand and all the manufacturing firms including cosmetic, pharmaceutical, nutraceutical, veterinary, paintball and food Industries are utilizing this machine on large extent to fulfill their bulk production tasks.

8.What Are The Different Support Devices For A Softget Encapsulation Machine?

The technology of softgel encapsulation machine is precise but comprehensive. The whole process of making softgel capsules is done by a single machine. However, for some additional tasks few devices are attached to the main machine for adding into its efficiency and perfection level. These auxiliary parts include:

Plunger Filling Machine

A plunger filling device is supportive component that has a major role in delivering the exact amount of therapeutic or any kind of liquid substances into softgel capsules.

Softgel Polisher

This part is needed after the final preparation of softgel capsules is done. It helps in the beautiful appearance of capsules by giving them shiny, glossy outer surface through polishing. Moreover, it eliminates the oil residue over capsules that are left during process.

Softgel Pulverizer

One of the most significant component can be named as a softgel pulverizer due to the major role it play in reducing the cost of production. It has the ability to grind the capsules which are improper or left from reaching the final stage and separate the shell and filling material so they can be used again.

Softgel Inspection Machine

Softgel inspection machine is comprised of rollers, mirrors and vibratory system. Its basic function is to examine the capsules from every angle and ensures the compliance of production with quality standards.

Water Chiller

Water chiller is a necessary device that should be used within a softgel encapsulation machine due to the function it performs. Its foremost task is to stabilize the temperature and cool it down by exerting the heat out from it.

Air Compressor

This component is integrated with the main body of machine for the purpose of accelerating production and bringing uniformity of capsulation mixture.

Tumbler Dryer

After the final preparation of softgel capsules, they are rolled down into a tumbler dryer for drying purpose. At that time, fan blower inside tumbler dryer cool down the capsules and they are collected into a cooling basket.

9.Compare And Contrast Between The Various Types Of Softgel Encapsulation Machine?

To find out the best solution among various types of softgel encapsulation machine you should first know their differences. Find it out by considering information given below:

| No | Factors | Large-Scale Softgel Encapsulation Machine | Small-Scale Softgel Encapsulation Machine | Small-Scale Softgel Encapsulation Machine |

| 1 | Nature | This machine has large size designed to process great volume. | This equipment is employed to carry out the moderate production. | With small footprint this machine accomplishes the task of producing softgel capsules less amount. |

| 2 | Process | Its process is comprehensive including gelatin rectification, preparing filling material, capsules: making, drying, inspecting, pulversing and polishing. | The process in neither too long nor too short. Starts with material preparing, capsule making, its delivering and drying | Mechanism is quite short eventually fast. Begins with processing raw material, producing capsules and simply ends in delivering. |

| 3 | Parts | It consists of numerous parts and can be integrated with auxiliary devices like chiller, polisher, dryer, inspection machine, pulverizer and many others. | It comprised of essential parts along with that few supportive devices can be added like fan blower and air compressor etc. | It only contains the basic components like hopper, tanks, die rollers, wedge and control panel etc. |

| 4 | Capacity | It has highest optimal capacity. | It has medium level capacity for producing softgel capsules. | It can only take small volume of softgel capsules. |

| 5 | Application | It has been utilized by big industrial sectors like pharmaceutical, cosmetics, food, nutraceutical etc. | Research institutes or domestic medicinal entities may use this equipment. | Areas like herbal processing sectors or healthcare institutes get benefited by this machine. |

| Machine |  |

|

|

|

10.Do You Know The Drawbacks Of A Softgel Encapsulation Machine?

Along with substantial benefits, every equipment encompasses few drawbacks. In this section we will display you some of the disadvantages of a softgel encapsulation machine such as:

Expensive Price

This machine has high initial cost due to its robust structure which is made with quality stainless steel. Moreover, the installation of a softgel encapsulation machine is also an expensive process. Thus it may burden you economically.

Labour Cost

Although, the machine is automatic but in the beginning it would requires proper skilled team of few members who are well aware of the entire mechanism of machine. Again it will raise the expenses in form of their salary.

Large Size

No doubt this machine has huge size and heavy weight which makes the movement of machine a very difficult task.

11.What Are The Possible Pitfalls that You Might Face When Using A Softgel Encapsulation Machine? Give Solutions For Solving These Problems?

A user of softgel encapsulation machine is likely to face some problems when operating a machine. What are these problems and how can they be solved is a question which can be understood by looking into the table below:

| No | Pitfalls | Reasons | Solutions |

| 1 | Gelatin ribbon is having breaks and grooves | Either cooling drum is not well lubricated or there is presence of any external object over the ribbon cooling drum | Solve it by lubricating the cooling drum with enough oil and must clean the surface for smooth performance |

| 2 | The softgel shell gets piled between oil and die roller | This is caused by the improper placement of die roller wedge or due to lose mangle rollers | The position of wedge should be adjusted to right place and also tightly press the mangle rollers |

| 3 | Gelatin ribbon is creating peeling problem and gets stuck on the cooling drum | It happens when temperature is high than required level | Reduce the temperature of gelatin liquid and the drum on which gelatin ribbon is processed because moderate temperature for cooling drum is essential |

| 4 | The final outlook of softgel capsule is dissymmetrical | Now this is a little bit serious problem because it affects the quality of capsules and the reason behind is uneven ribbons with dissimilar thickness | Adjust it by making sure that both the gelatin ribbons required for process is carrying same thickness |

| 5 | The softgel shell is looking like concave | The reason may be the bad quality of ribbon or the disturb level of ribbon thickness | Tackle the issue by replacing gelatin liquid with one having good quality and adjust the thickness of gelatin cover |

12.What Is The Installation Process For A Softgel Encapsulation Machine?

Right installation of such a heavy and large size machine is very crucial which can be understood by following steps:

First Step: Assembling the Components

Assembling is the process of putting together the components of machine in a particular order so their degree of precision could be well maintained. In initial step do check that all parts are in place then to connect them with screws or bolts. In addition, you need to be aware of the proper connection of electrical wires, pipes and other devices.

Second Step: To Contact the Technician for Assembling

A person having years of experience in installing the same machine can better assist you in installation and will also provide you the knowledge about how much time the machine would take to process. Thus you have to contact the experienced

Third Step: Location for Installation

Location is the crucial factor if you are going to install a softgel encapsulation machine. The place should be decided by the technician where there would be no disturbance during operation like noise or dust etc which may affect the quality of capsules.. Moreover, the large size of machine demands a permanent location for installation.

Fourth Step: Ventilation for Installation

You should decide the place that is well ventilated and has access to electricity so that toxic gases that might generate during the process can be immediately exiled from the room. In addition, the free flow of air around the machine let it to perform smoothly in fresh environment.

13.Highlight The Important Factors Which Play Essential Role In Selecting Best Softgel Encapsulation Machine?

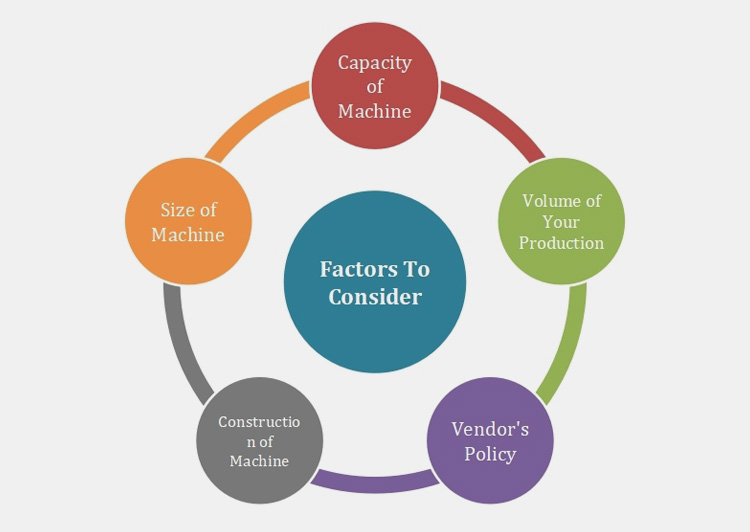

After knowing all the important questions about a softgel encapsulation machine, there comes another crucial aspect of the machine that is associated with factors which are necessary to be considered before purchasing a softgel encapsulation machine. What are these factors is what we have explained below:

Capacity of Machine

This question is of prime importance as it will determine your production volume. Choose a machine with tank and hopper having great capacity so that your material would not get stuck during process.

Size of Machine

Industrial owners often select a machine that has large volume and big size. But they don’t have enough room for setting it or in some cases they have to mobilize it from one place to another. In this situation, it becomes difficult to handle and move such heavy equipment. So, you should keep this point in your knowledge and go for one that compliments your needs.

Volume of Your Production

This factor is linked with your production line. If you are manufacturing ordinary level of softgel pills on daily basis then machine with small and medium size capacity would be a good choice with reasonable price. Similarly, if the volume of your production is so high that it reaches to formulate thousands of softgel capsules on regular basis then large scale machine is the best answer.

Construction of Machine

Always opt for machine whose material is durable with strong resistance against environmental conditions. Also check the availability of various parts because extensive range of tooling can better manufacture the capsules with different shapes and sizes.

Vendor’s Policy

Remember that success of your business is indirectly linked to the supplier you choose for buying your capital in form of machinery. That is why; a reputable and renowned brand is always preferred because of the vendor’s excellent policy. Besides, they also provide their customers with full remote support and assist them in case of parts replacement or installation etc.

Conclusion

To summarize, we hope that you have got complete idea about the softgel encapsulation machine. Now when you are well-acknowledged to the facts and figures we have provided above what is your next move? If you are serious and considering to purchase a softgel encapsulation machine, there is no need to hesitate. Allpack is always ready to answer its customers, just click on the link and approach us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours