Best Option For Manual Capsule Filling Machine

- Circular Arc Shape

- High-quality Plastic Material

- Accurate and Precise Filling

Manual Capsule Filling Machine

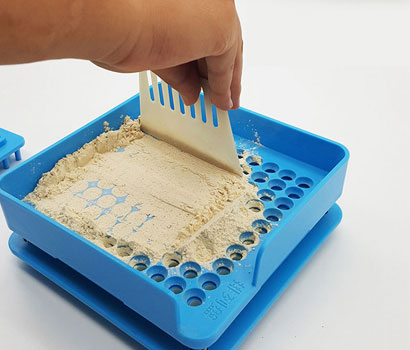

Allpack manual capsule filling machine can fill various number of capsules at a time. It is composed of body plate, cap plate, middle plate, arrangement plate, powder pressing plate and scraping plate. The overall color is bright, the toughness is good, and the material is thick. It meets the hygienic requirements for the production of medicines and food; the size is precise, the use is simple, the filling is fast and convenient, and the filling volume is uniform; the automatic arrangement of the machine is designed, the capsule arrangement speed is fast, and the automatic arrangement rate is high; the whole board is automatically arranged and the whole board is filled. It is an ideal non-mechanical capsule filling tool in China due to its high efficiency and high qualified rate of capsules.

Manual Capsule Filling Machine

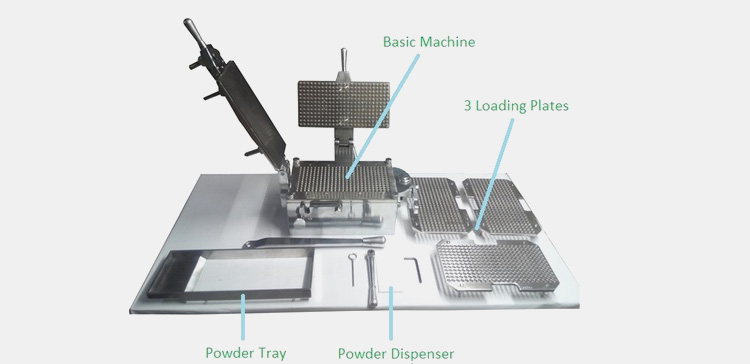

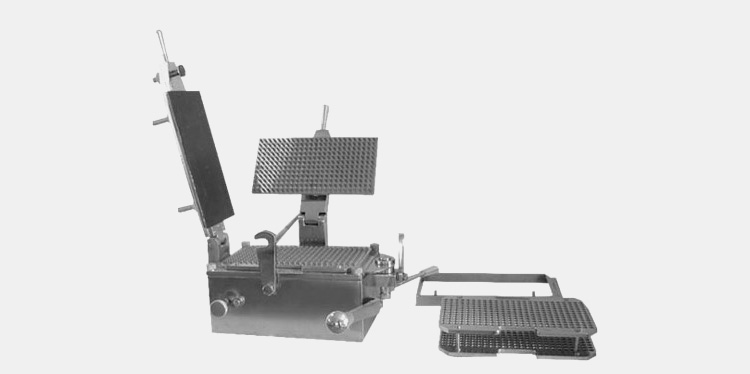

AS-100 Manual Capsule Filling Machine

Allpack AS-100 manual capsule filling machine is suitable the process and production for small-amount homemade capsule, Like for small factory, pharmacy, sample room, lab, department of pharmaceutical preparation in hospital, family and so on.This manual capsule filling machine includes 6 parts: Body Plate, Alignment Plate, Cap Plate, Middle Plate , Powder Spreader, Powder Pressing Plate.The capsule includes 2 parts: the capsule body, (the long one, filled with powder), the capsule cap (the short one, no powder).

Capsule Size Option: 00#, 0#, 1#, 2#, 3#, 4#

Adopting high quality plastic material

Higher accuracy, less powder leakage

AS-187 Manual Capsule Filling Machine

Allpack AS-187 manual capsule filling machine can be used for filling with 100 capsules at a time. It consists of body board, cap board, middle board, arrangement board, powder board, and scraper board. It has bright overall color, good toughness, and thick material. It is made of new environmentally friendly food grade new materials.

Imitate automatic mechanical arrangement

With precise and unique design

Durable for long term use

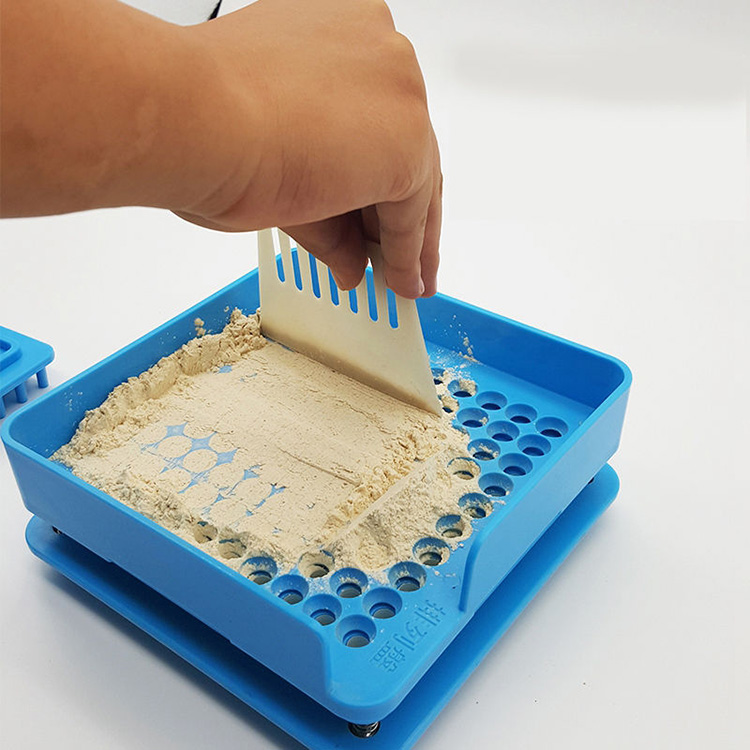

AS-209 Manual Capsule Filling Machine

Allpack AS-209 manual capsule filling machine,the operation is very easy. It can make uniform capsules at high efficiency. The capacity is about 3, 000-10, 000 pcs/h. It is extensively applied in hospital, lab, little pharmaceutical factory.The machine adopts high quality plastic material, which is more durable for long term use.It is surrounded by circular arc shapes, which has beautiful appearance and bring you comfortable operation.

Precise and unique design

Imitate automatic mechanical arrangement

Small batch processing, production

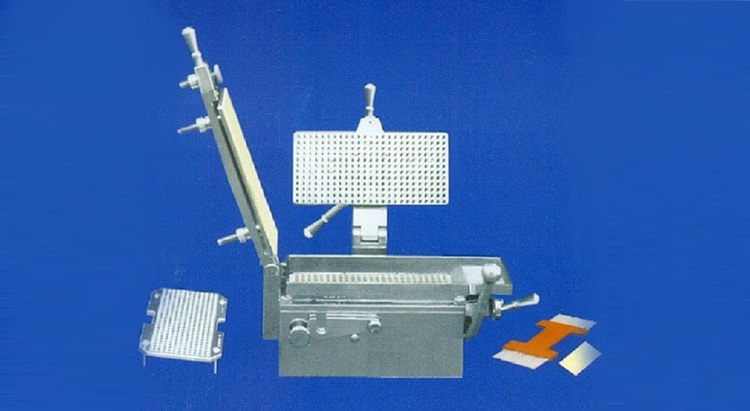

AS-400 Manual Capsule Filling Machine

Allpack AS-400 manual capsule filling machine adopts high quality plastic material, which is more durable for long term use. With its unique design, it is easy to operate and effective to reduce wasting. Imitate automatic mechanical arrangement, you can arrange capsules cap and capsule body quickly, very convenient to use. Effective to deal with the problem of filling capsule, like small batch processing,production, self-made capsules. Such a wonderful goods, just bring it home!

Suitable for Capsule Type: 000# 00# 0# 1# 2# 3#

Higher accuracy, less powder leakage

Convenient to use

AS-600 Manual Capsule Filling Machine

Allpack AS-600 manual capsule filling machine ,its raw material is imported acrylic which is healthy, good transparency, durable, low weight.The screws & pins are made of stainless steel and meet the hygiene requirement GMP standards.The cap sheet adopts one-layer design and polished angles to prevent bleeding.The middle sheet adopts special flute design of high precision, which can avoid the breakage of capsules when joining them.The body sheet adopts the specially-dealt screws and springs, which can make no noise when pressing downwards.

Design powder guard

Avoid loss of powders

Meets the hygienic requirements

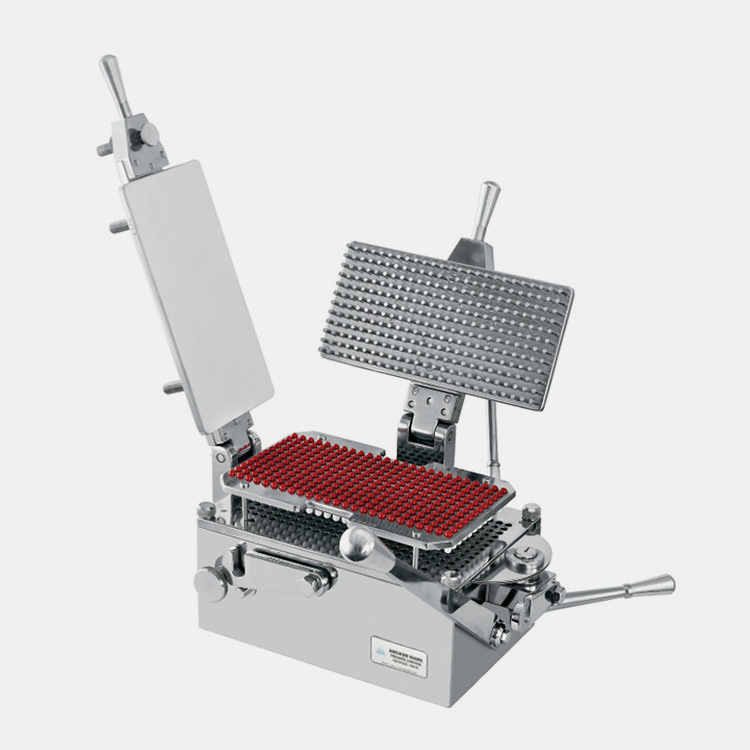

AS-800 Manual Capsule Filling Machine

AS-800 manual capsule filling machine solves the problem of capsule filling in small batch processing, production and self-made capsules. Traditional Chinese pharmacies, pharmacies, tonic health products stores, scientific research institutions, laboratories, households, etc. This manual capsule filling machine can be used for filling (filling) hollow capsules, and are also a backup alternative tool for automatic capsule filling machines. Product advantages: The capsule filling plate is completely designed and processed according to the characteristics of hollow capsules and the principle of the capsule filling machine.

Healthy, good transparency,

Durable, low weight

Meet the hygiene requirement GMP standards

The Buyer's Guide

Manual Capsule Filling Machine: The Complete Buying Guide In 2025

Are you looking for a labor-saving solution to boost your capsule filling process? If so, you are at the right place. Manual capsule filling machines are an ideal way to produce large amounts of filled capsules quickly. Not only do these machines save time and money compared to hand-filling, but they can also offer increased accuracy and safety benefits over manual methods.

In this blog post, we’ll take an in-depth look at how manual capsule filling machines work and the many advantages they bring with them. Read on to find out more!

1.What Is A Manual Capsule Filling Machine?

A manual capsule filling machine is an essential tool for any business that produces supplements, vitamins, medicines, or other products in the form of capsules. These machines vary in size and complexity, but they all work the same way. This manual device can quickly and efficiently fill your hard or soft gelatin capsules with various materials, such as powders, pellets, granules, and tablets.

Depending on the type of manual capsule filling machine, you can customize the number of ingredients you fill each capsule with. Some models also allow you to choose different capsule sizes, so you can easily fill your capsules with the right amount of ingredients every time.

Additionally, manual capsule filling machines are generally very easy to use and operate, making them a great choice for beginners or anyone who wants to prepare their supplements conveniently at home.

2.What Are The Components Of A Manual Capsule Filling Machine?

The manual capsule filling machine comprises several components that work together to fill capsules with various types of medications and supplements. These components include:

Hopper

This component is used to hold the powder that needs to be filled into the capsule. It has an adjustable vibrator to ensure the even distribution of the powder.

Dosing Station

The dosing station is responsible for transferring the powder from the hopper into the capsules. This component has adjustable settings to control the amount of powder that is filled in each capsule.

Capsule locking plate

The capsule locking plate securely holds the capsules, allowing the ejector system to move precisely without spilling any powder.

Manual control panel

It is used to adjust the settings of the manual capsule filling machine allowing for more precise control over the dosage and accuracy.

3.What Are The Advantages Of A Manual Capsule Filling Machine?

Cost effective

A manual capsule filling machine is a simple and cost-effective option if you want to fill capsules quickly and easily at home or in a small office setting.

Affordable

Manual capsule filling machines can be affordable since they don’t require electricity or other power sources. This means you can use them almost anywhere without worrying about having access to power.

Simplicity

Compared to automated, semi-automated, or fully automated capsule filling machines, manual machines tend to be simpler in design, requiring fewer moving parts and thus fewer potential points of failure.

Easy to use

Manual capsule filling machines are easy to operate, which allows anyone with basic training to learn how to operate one quickly. Also, this can help you to save time, reduce errors, and increase efficiency in your production process.

Compactness

Manual capsule filling machines are often more compact than other capsule fillers, making them an ideal choice for smaller spaces such as home offices or limited workshop areas.

Low Maintenance Operations

Manual capsule filling machines are easier to maintain and repair since they require less technical knowledge and skill. This can be a big advantage if you have little experience with capsule filling in general.

Precise filling and Accuracy

Manual capsule filling machines often offer superior precision and accuracy compared to other fillers, allowing you to achieve consistently high-quality results every time.

4.What Are The Applications Of A Manual Capsule Filling Machine?

Manual capsule filling machines are versatile tools used in various industries to help streamline and improve the production process. Such industries include:

Pharmaceutical Industries

A manual capsule filling machine is commonly used in the pharmaceutical industry to efficiently and accurately fill capsules with predetermined dosages of powder or liquid medications, depending on the requirement for each particular medication.

Nutraceutical Industries

A manual capsule filling machine is a useful tool for businesses in the Nutraceutical Industries. This machine allows you to quickly and easily fill capsules with powdered ingredients, making it ideal for manufacturing dietary supplements and other health-related products.

Herbal Supplement Industries

Manual capsule filling machines can fill capsules with dried herbs and extracts that consumers typically prefer for their natural composition and purported health benefits.

5.How Does A Manual Capsule Filling Machine Work?

A manual capsule filling machine consists of several compartments filled one at a time with the desired material and then sealed shut to create individual capsules. The manual capsule filling process involves several stages.

The first step is to prepare the raw material and place it into a hopper that feeds into the manual capsule filling machine. The raw material is then manually transferred to individual capsules using a manual dose. This manual helps ensure that each capsule is filled with an accurate measure of the powder or material used.

The next step in the manual capsule filling process is to place each filled capsule on a movable platform. Depending on the manual capsule filling machine’s size and configuration, this platform can be adjusted to fill the desired number of capsules.

Once all of the capsules are filled and placed into the movable platform, they must be closed to prevent any material from spilling out. The manual capsule closing process involves placing a manual capsule closing disc onto the platform and manually moving it to close each capsule.

This manual movement helps ensure that each capsule is securely closed and won’t open during transport or storage. Once all of the capsules are filled and closed, they can be ejected from the manual capsule filling machine into a collection tray for further processing or packaging

6.What Are The Different Types Of Manual Capsule Filling Machines Available On The Market?

Several manual capsule filling machines are available on the market, each with unique features and benefits. Some of the most common types include

Manual Single Station

Manual single-station capsule filling machines are typically smaller and easier to use than other manual capsule fillers. These machines are ideal for home users or small businesses that need to fill a low volume of capsules regularly.

Components

They typically consist of a motor-driven turntable with multiple wells for holding empty capsules as well as an attached hopper where powdered ingredients are added by hand through a funnel.

Working Principle

This machine uses precision feeding devices and an accurately calibrated metering mechanism to ensure that each capsule receives the correct material. Additionally, this machine typically consists of multiple compartments for storing the different types of powders or granules and a collection cup or chute to collect and dispense the filled capsules.

b) Manual Double Station

Manual double-station capsule filling machines are larger and more complex than manual single-station machines.

Components

Like manual single-station machines, manual double-station filling machines consist of a motor-driven turntable, multiple good stations for holding empty capsules, and an attached hopper for adding powdered ingredients by hand.

However, manual double-station machines also have additional features, such as an automatic shutoff function that stops rotation once all wells are filled with powder. This prevents overfilling or under filling capsules and results in a more consistent dosage per capsule.

Working principle

This machine utilizes mechanical components like gears, levers, and belts to move the capsules from station to station as they are filled. At the heart of this system is an inclined conveyor belt that moves capsules from one station to the next, transporting them through each step of the filling process.

As the capsules move along the conveyor belt, they are guided into position using a series of rollers and guides, ensuring that they are always oriented properly for filling. Once in position at each station, specialized nozzles dispense precise amounts of powder or granules into each capsule.

Depending on the filling being done, manual or automatic controls may be used to adjust the speed and pressure of this dispensing process. Once each capsule has been filled, it moves along the conveyor belt to the next station for additional processing, if necessary.

c) Manual Triple-Station

Manual triple-station capsule filling machines are the most advanced type of manual capsule filler available on the market.

Components

Like manual double-station machines, manual triple-station machines feature a motor-driven turntable with multiple good stations for holding empty capsules and an attached hopper for adding powdered ingredients by hand.

However, manual triple-station fillers also have built-in scales that automatically weigh each dose as it is added to the capsules, ensuring a consistent dosage per capsule.

Additionally, manual triple-station filling machines are typically equipped with safety mechanisms that prevent you from accidentally overfilling or under filling capsules.

Working principle

This machine uses a series of rotating augers that accurately dispense precise amounts of product into each capsule as it moves along a conveyor belt. Each station is equipped with its own set of augers, and the capsules are fed through the machine in an assembly line fashion, with each station loading and sealing a different component into the capsules.

7.What Materials That Can Be Filled In Capsules Using A Manual Capsule Filling Machine?

A manual capsule filling machine can be used to fill different types of products in capsules including:

Powder

powder is one of the most common ingredients used in capsule shells, providing a strong base upon the other ingredients to build upon. The powder is typically made up of finely ground active ingredients combined with other additives that help it flow smoothly into the capsule shell

Granules

Granules are another powder that can be used to fill capsules. These smaller particles are typically formed by grinding larger granular ingredients into a finer texture, and they can often be mixed with other ingredients to create customized blends.

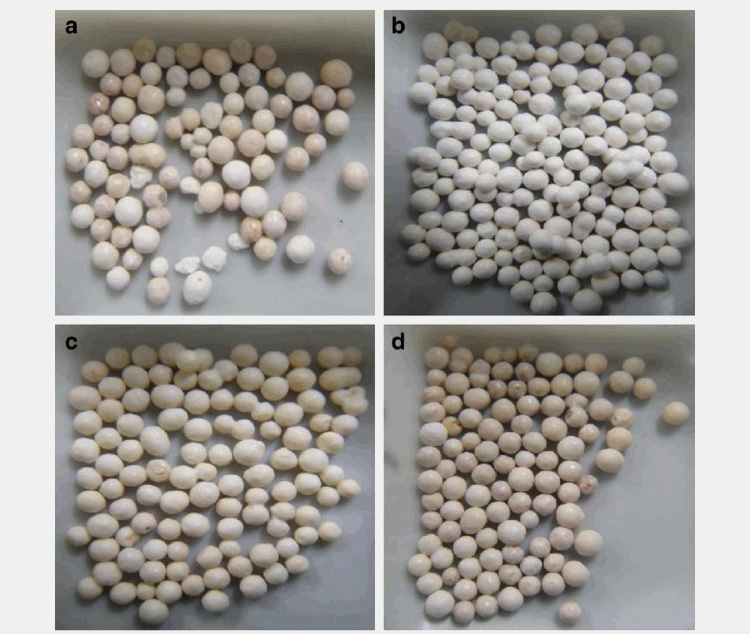

Pellets

These are another common type of product you can fill into capsules using manual capsule filling machines. Pellets are typically made by compressing and shaping a powder or granule mixture into small, cylindrical shapes. Unlike granules, pellets retain their shape even after they have been exposed to moisture or temperature fluctuations.

8.What Types Of Products Can Be Produced In Capsule Form Using A Manual Capsule Filling Machine?

The manual capsule filling machine is a great way to quickly and easily produce capsules of various sizes with whatever ingredients you desire. They include:

vitamins

Vitamins are an ideal product to be produced in capsule form using a manual capsule filling machine. Many vitamins, including vitamin B12 and vitamin C, can easily be encapsulated into capsules for easy ingestion.

Minerals

Minerals are an important type of product that can be produced in capsule form using a manual capsule filling machine. Mineral capsules are usually filled with pure, powdered minerals such as iron, magnesium and calcium which can be easily measured out for accurate dosage.

Medicine

A manual capsule filling machine is an easy to use device that allows for quick filling of medicine capsules.

Supplements

Supplement capsules are a type of heath supplement used to deliver vitamins, minerals or other beneficial ingredients in an easy to swallow form.

9.How Can You Ensure Quality When Using A Manual Capsule Filling Machine?

One of the main challenges facing manual capsule filling machines is ensuring quality during the filling process. However, you can maintain quality in several ways, including

Pay Close Attention to The Quality of Your Inputs

The first step in ensuring quality when you are using a manual capsule filling machine is to pay close attention to the quality of your inputs. This means ensuring that you are only using high-quality ingredients when preparing your capsules.

Monitor Dust Levels Closely

Another key factor in ensuring quality when using manual capsule filling machines is monitoring dust levels closely. Dust can interfere with the consistency and flow of your capsules as they move through the machine, so it’s important to minimize this risk by using filters or enclosing machinery where possible.

Perform Regular Maintenance Checks

In addition to monitoring dust levels and ensuring the quality of your inputs, it’s important to perform regular maintenance checks on manual capsule filling machines. This includes checking for wear-and-tear, making sure all parts are correctly aligned, and running occasional tests to ensure that everything is working as expected.

Use Clean Containers

When you are using manual capsule filling machines, it’s important to use clean containers for storing, mixing, and measuring ingredients. This helps minimize the risk of contamination or mix-ups as well as ensuring that your capsules are uniform in size and shape.

Take Advantage of Automated Features

Many manual capsule filling machines come equipped with automated features such as counters, timers, and scales. These features can be used to ensure that capsules are filled with the correct amounts of ingredients, as well as tracking and documenting production.

Adjust Machine Settings

In order to get the most out of manual capsule filling machines, it’s important to adjust machine settings according to the type of capsule being filled. This includes adjusting things like speed, pressure, and temperature in order to achieve the desired results.

Invest in Quality Tools and Accessories

To ensure that your manual capsule filling machines are working properly, it’s important to invest in high-quality tools and accessories such as nozzles, funnels, tamping devices, and other related items. These items help ensure that capsules are filled with the correct ingredients and in the right quantities.

Use Automated Quality Control Systems

Automated quality control systems can be used to monitor manual capsule filling machines for errors and inconsistencies. This helps ensure that all capsules are uniform in size, shape, and weight and helps reduce production costs by minimizing waste.

Follow Safety Protocols

Safety is paramount when using manual capsule filling machines, so it’s important to follow all safety protocols and procedures. This includes wearing protective clothing, avoiding contact with hazardous materials, and understanding how to safely operate the equipment.

Store Capsules Properly

Finally, manual capsule filling machines require proper storage of the finished product in order to ensure quality. This includes labeling the capsules correctly, storing them in an area with low temperature and humidity levels, and keeping them away from direct sunlight or other sources of heat.

10.What Are The Common Challenges Associated With Using A Manual Capsule Filling Machine And Their Possible Solutions?

Inaccurate measurement and dosing

Since the manual capsule filling machine relies on manual input for dosage measurements and fills volumes, there is a risk that these values will not be more accurate and consistent from one batch to the next. This could compromise the effectiveness of the medication and lead to unwanted side effects for patients.

Solution

Using a scale with higher accuracy and investing in an automated system that uses sensors to ensure the correct weight is dispensed for each pill.

Risk Of Contamination

A manual capsule filling machine requires close contact with potentially harmful chemicals and materials, increasing the risk that these substances could come into contact with the capsules and result in contamination. This could lead to negative side effects for patients or even render their medication ineffective.

Solution

Investing in an automated machine that offers precise dosing and has better containment technology to prevent powder leakage or cross-contamination.

Inconsistent Capsule Sizing

Another common challenge associated with manual capsule filling machines is the inconsistent sizing of individual capsules. Since the manual operation of these machines is performed by hand, there can be a lot of variation in the size and shape of individual capsules from one batch to the next.

Solution

Investing in a manual machine with adjustable settings or an automated machine that uses sensors to automatically detect and select the correct capsule size.

Poor Dosing Control

Manual capsule filling machines can be inconsistent in how much powder is dispensed into each dose, leading to uneven capsules.

Solution

Investing in a manual machine with better dosing controls or an automated system that uses sensors to precision-fill each pill.

Operator Fatigue

Manual machines require manual operation and this can lead to operators getting tired quickly

Solution

Include investing in an automated machine that can reduce manual labor and provide more consistent results, as well as implementing ergonomic practices to reduce operator fatigue.

Operator Error

Manual capsule filling machines are prone to operator errors which can lead to product waste, misfiling, and poor quality capsules.

Solution

Training operators on proper use of manual capsule filling machines, implementing visual instructions, or investing in an automated machine to reduce manual labor and errors.

Expensive Maintenance and Repair

Due to the limited design and construction of manual capsule filling machines, they often require frequent maintenance and repairs to continue operating at peak performance levels. This can be costly over time and increase overall operational expenses significantly.

Solution

It is important you closely inspect your machine for any signs of damage or wear and Schedule regular maintenance checks for your manual capsule filling machine with an experienced technician or factory representative

11.What Are The Maintenance Procedures Of A Manual Capsule Filling Machine?

Manual capsule filling machines require regular maintenance to ensure optimal performance and effectiveness. Some key maintenance procedures for manual capsule filling machines may include the following;

- Ensure that the manual capsule filling machine is clean and properly maintained. This can be done by regularly wiping the machine with a damp cloth and removing debris or buildup from its surfaces.

- Monitor and replace any worn out or damaged parts of the manual capsule filling machine as needed. This may include replacing belts, seals, motors, gaskets, and other components prone to wear out over time.

- Schedule regular maintenance checks for your manual capsule filling machine with an experienced technician or factory representative. These inspections will allow you to identify any areas of concern early on and address them before they become more serious issues that could impact performance and productivity.

- Keep the manual capsule filling machine in a cool, dry place away from direct sunlight. Exposure to excessive heat and humidity can damage the machine’s components over time, so it’s important to take measures to protect it from these conditions.

- Follow manufacturer guidelines or instructions regarding cleaning chemicals or other substances with your manual capsule filling machine. These substances may harm certain parts of the machine if they are not handled properly, so it is important to follow all safety precautions when using them.

- Keep an eye on the consumable parts used with your manual capsule filling machines, such as capsules and fillers. Keeping a consistent supply of these items on hand will help ensure that you have everything you need for the machine’s smooth operation.

- Make regular backups of important data and files related to your manual capsule filling machines, such as production logs or user settings. This will help you maintain performance and ensure that you can make quick repairs or adjustments if necessary.

12.What Are The Key Factors To Consider When Selecting A Manual Capsule Filling Machine For Your Business?

Cost And Affordability

When selecting a manual capsule filling machine for your business, you should consider the cost of the machine and whether or not it fits within your budget. Also, consider looking for machines made by reputable brands that offer affordable pricing options so that you can get the most value for your money.

Ease of use

Another key factor you should consider when selecting a manual capsule filling machine is how user-friendly it is. Look for models that are easy to operate and don’t require a lot of training or technical knowledge to use effectively.

This will help ensure you can start using your new machine immediately without hassle or difficulty.

Productivity

In addition to being easy to use, your manual capsule filling machine should also be able to produce enough capsules for your business needs. When evaluating different machines, look for ones that can fill up to a certain number of capsules per minute or hour to get the most out of your investment.

Portability

If you plan on moving around with your manual capsule filling machine often, it is important to find one that is lightweight and portable. Look for compact models with wheels or handles so that they are easy to transport from place to place.

Efficient Design

A manual capsule filling machine should have an efficient design and layout, with features like an ergonomic grip and a large opening for easier loading and unloading of capsules. This will help ensure that your machine is easy and comfortable to use, even for long periods.

Safety Features

Another key consideration when selecting a manual capsule filling machine is its safety features. Look for models that are designed with safety in mind and come equipped with features like automatic shutoff mechanisms, protective guards around dangerous moving parts, and security seals to prevent spills or accidents.

Customizability

If you have specific product requirements for your manual capsule filling machine, look for one that allows for customizability so that you can adjust its settings to meet your needs exactly. Customization options include adjustable fill levels, speed controls, or different capsule sizes.

Durability

A manual capsule filling machine made from high-quality materials and components can be expected to last longer and withstand heavy use. Look for models that are built to last and have sturdy construction so that you can get the most value from your purchase.

Quality of Capsules

In choosing a reliable manual capsule filling machine, it is also important you consider the quality of the capsules produced by the machine. Ideally, it would help if you looked for one that produces consistent, uniform capsules with minimal complaints or issues.

Support and Maintenance

Finally, when selecting a manual capsule filling machine for your business, remember to factor in support and maintenance needs. Choose a model with good customer service support or a warranty so you can get the help you need if any issues arise.

Additionally, look for a manual capsule filling machine that is relatively easy to maintain, with components that are simple to clean and replace as needed. With these considerations in mind, you can feel confident in your choice of manual capsule filling machine for your business.

13.Why Choose Allpack For Your Manual Capsule Filling Machine?

Quality Assurance

Allpachchina company manufactures manual capsule filling machines as per International standards; hence you can be assured about the quality of your products.

Expert Manual Capsule Filling Machine Manufacturer

We have a vast experience in high-quality manual capsule filling machine manufacturing. With this experience, we have gained unmatched expertise in all aspects of manual capsule filling machines

High-Tech Modern Technology

We lead the manual capsule filling machine manufacturing industry with continuous innovation and technological adaptation. Additionally, we manufacture manual capsule filling machines as per customized requirements.

Highly Experienced Team

Also, we have a highly experienced team who are very dedicated and passionate with work.

CONCLUSION

At Allpack, we provide high-quality manual capsule filling machines that are easy to use and offer a wide variety of functions. If you are looking for a machine that can help you easily fill capsules, look no further than Allpack. Our team of experts would be more than happy to help you find the perfect device for your needs. Contact us today to learn more about our products and how we can help you take your business to the next level.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours