video:

Introduction:

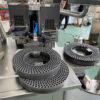

Double head semi-automatic capsule filling machine adopts double head seeding device, which relates to the technical field of the seeding device.The main part of the double head semi-automatic capsule filling machine is the operating platform, and on the top of the operating platform is fixed with two bases, the top of both bases is welded with long blocks, the top of the long block is near the edge of one side and a support block is welded at the top of the support block, and the top of the conveying block is fixed with a material frame.

Through the start of the second electric push rod, the push capsule plate of the double head semi-automatic capsule filling machine pushes the capsule inside the pressure capsule groove to the edge of the pressure capsule groove, and through the start of the first electric push rod, the pressure capsule plate presses the capsule inside the capsule tank, so that the capsule enters into the inner part of the capsule groove at the top of the capsule disc, and then makes the capsule disk rotate through the motor.Then through the same procedures, the capsule can be effectively seeded into the inner of the capsule tank, and the double head method can effectively improve the efficiency of the capsule in use, and facilitate the subsequent processing of the capsule.

Feature:

1.The whole machine adopts programmable control system, touch screen panel operation, stepless frequency conversion debugging and pneumatic joint control.

2.In the design of the equipment, the double head semi automatic capsule filling machine is adopted. Compared with the old semi-automatic capsule filling machine, the speed, mold replacement, filling degree and maintenance of the double head automatic capsule filling machine have made obvious progress. The equipment has become more rapid, convenient, simple and stable. In the aspect of capsule locking, we use pneumatic control and automatic capsule locking to save labor time.

3. In terms of man-machine, our company has installed a safety door device in the bag pulling station. When the safety door is not closed, the equipment is in a static state and cannot run. In the powder filling station, a visual window is added to observe the powder loading degree. A barrier plate is installed on the lock pocket position to avoid accidents when the lock pocket is turned over. The right side of the equipment is equipped with a capsule tray rack, which is convenient for application.

4. The fuselage and worktable are made of stainless steel to prevent corrosion and oxidation.

5.The equipment can be used to fill different types of capsules, which can be used to fill hard capsules of medicines and health care products such as powders, granules and pellets.

Specification:

| Model | CGN-208S |

| Productivity | 3.8-4.3 capsules/h |

| Applicable capsules | 000#、00#、0#、1#、2#、3#、4#、5# |

| Filled medicine type | Not adhensive or wet powders, and small granules |

| Total power | 2.12kw |

| Air pressure | 0.03m3/min 0.7Mpa |

| Vacuum pump | Evacuating rate:40m3/h |

| Dimension(L*W*H) | 1130X700X1600(c m3) |

| Weight | 500kg |

| Carton Packaging Dimension | 1650X720X1800(c m3) |

Reviews

There are no reviews yet.