10 Things You Should Know About Industrial Packaging

Packaging of Industrial products is a part of today’s life. Just like homes and workplaces prepare packages for food and beverages, companies also prepare special packages for their product.

Every physical product must be delivered from the manufacturer to the customer. Packaging is important to ensure your belongings are fully protected throughout their journey. Industrial Packaging is vital for any company that ships or delivers products to customers.

Whether they are retailers, wholesalers, distributors, or even e-commerce sites selling products from around the world, they rely on print packaging to provide protection and security before their products reach their customer. This blog ‘10 Things You Should Know about Industrial Packaging’ is what you need to know about commercial packaging.

1.What is Industrial Packaging?

Industrial Packaging- Picture Courtesy: The Economic Times

Industrial packaging is a container designed for commercial use. This means that industrial packaging is often used in manufacturing or distribution. Warehouses and factory move and store their products using industrial packaging. It is a means of preparing product for shipment, retailing, and delivery. By industrial packaging, brands can protect their product and keep them safe.

From medicines to syringes, beverages to food and everything is packed with industrial packaging. So, it must be strong and durable. It should facilitate transportation and storage and protect the contents from impacts, crushes or spills during transportation.

Products also require registration, tracking and some advertising which is accomplished with industrial packaging. it is also important in product communication, as, instructions for use or warnings are labeled outside the packaging.

2.Significance of Industrial Packaging

Significance of Industrial Packaging

Yes, manufacturers use industrial packaging because it comes with a wide set of benefits, some of which are listed below:

Containment

Industrial packaging with greater containment

The main purpose of industrial packaging is to contain the product for storage or transportation. It encloses the product and prevents them from breaking free. Hence, it averts their spilling and creating a mess. Furthermore, it is generally heavy-duty and versatile; it is designed to transport large loads, from hazardous waste to food.

Protection

More and more Protection with industrial Packaging- Picture Courtesy: Dieline

One of the important purposes of the industrial packaging is to protect the product from environmental and biological elements. Furthermore, it also protects product from mechanical damage like spilling, crushing, tearing, etc.

Safety

Offering Originality- Picture Courtesy:Arka

It can also play an important role in keeping your products safe against counterfeiting, tampering, theft, and fraud. Nowadays, industrial packaging contains tamper proof mechanisms like tapes, and seals that prevent tampering. It is also designed with holographic labels, QR codes, and fluorescent films to stop fraudulent and counterfeiting activities.

Brand Imaging

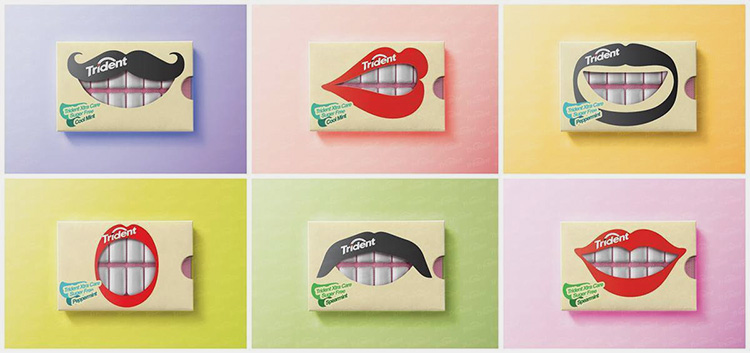

Maximum Market Value with Industrial Packaging

Striking and stylish industrial packaging on retail shelves builds a connection with a customer. Brands use industrial packaging for brand advertisement. A unique industrial packaging goes a long way in building brand's image in minds of consumers. Moreover, it is a way to stand out from the competition.

3.10 Things You Should Know About Industrial Packaging

Industrial packaging is an essential part of the manufacturing process and allows commercial grade products and products to be protected during handling and transportation. It comes in many shapes and sizes, with many accessories to choose from. Every product has its own unique requirements when it comes to packaging, so it's important to understand which type of industrial packaging will work best for each issue.

4.Innovative Trends Industrial Packaging Offer you

The packaging industry is using smart and sustainable solutions to make packaging better for consumers, brands, and the environment. The main innovative industrial packaging includes, smart packaging, internet packaging, interactive packaging, and nano technology.

Smart Packaging

Smart packaging refers to the packaging technology with electronic technology for food, medicine and many other products. It is used to extend shelf life, monitor freshness, display quality information, and increase product and customer safety.

Interactive packaging

It is designed to inspire and engage customers. The customer's curiosity is encouraged and the bond between the customer and the product comes with the packaging, expressed in its ability to "entertain” and invite the customer.

Recyclable and Sustainable Packaging

The challenge for brands is to increase product visibility by boosting sales and one way to do so is by recyclable industrial packaging. With countries banning the use of single-use plastics, companies are now looking for alternative packaging materials to comply with regulations.

Nanotechnology in Industrial Packaging

Nanotechnology is trendy at every stage of packaging, from manufacturing to product safety, from certification to tracking. The use of nanoparticles mixed with a polymer chain increases the barrier properties and tensile strength of the container. It can also help companies and packages monitor and prevent violations.

5.Types of Material Industrial Packaging Mostly Use

The most common packaging materials include:

Materials of Industrial Packaging- Picture Courtesy: Placon

Plastic:It prevents diseases such as bacteria found in products produced, distributed and stored for use in medical facilities.

Glass:Glass is a good container for pharmaceutical products such as tablets, capsules, syrups and suspensions in glass bottles, as well as sterile products in ampoule or vial form.

Aluminum:Aluminum foil completely blocks light, oxygen, moisture and bacteria. Foil is widely used in food and pharmaceutical packaging. Aluminum foil is also used in sterile packaging production.

Paper: Paper and paperboard are used in ice containers, microwave food bags, baking trays, milk cartons, pizza and other fast food packaging, beverage containers, etc. is used.

Cardboard wood: The main purpose of cardboard packaging is to protect items that need to be stored and transported. This is a broad look at paper packaging; because the truth is that paper can be used to store everything from electronic devices to household items.

6.An effective way of Transporting Goods

An effective way of Transporting Good- Picture Courtesy: D freight

Air, land, sea and rail. These are the four main types of transportation in the logistics industry. Which method you use depends on what you're sending, where you're sending it from, and where you live. However, there may be more than one suitable method. That's why it's important to understand the pros and cons of each shipping method. You also need to decide which means of transportation can carry the most according to your needs.

7.The design for Durability & Safety of Items

Durability & Safety of Items- Picture Courtesy: Kao Colin

Industrial packaging is designed for durability and safety of the items. It acts as a silent safeguard and keeps the products intact on the journey from manufacturers to consumers. Tough materials, for instance, cardboard or bubble wrap act as cushioning and prevent the breakage, dents, snaps, etc. of products on their way. They are shock absorbers because their function is to absorb transportation vibrations.

The aim is to ensure that the product is resistant to normal wear and tear and potential hazards, while ensuring the safety of the user when they wish to use the product. The important thing is to create products that are long-lasting and prioritize the health of the people who use them.

8.New Designs for Products, Sizes & Weight

Products Size & Weight Design- Picture Courtesy: Tecno Soluciones

There are always innovations and trends in the packaging industry with new models according to product sizes and weights. Businesses are constantly looking for ways to improve the packaging to be efficient, environmentally friendly and optimal. There are a few key trends in the market when it comes to designing for product size and weight.

Right-sizing

It means creating containers that fit the product and minimizing the waste. This helps reduce material and transportation costs.

Light-weighting

Lightweight package materials or items reduce weight without sacrificing strength or protection. This helps reduce overall weight and environmental impact.

9.Capability to Combat Environmental Conditions

Industries are using many strategies to deal with environmental issues in industrial packaging. They use materials that are resistant to moisture, temperature changes or UV rays. Moreover, some packaging designs include features such as seals or barriers that will protect the content from other factors. The company also conducts stringent testing to ensure its packaging can withstand various environmental conditions during transportation and storage.

10.Greater Way for Marketing Products

Marketing Tools for Products- Picture Courtesy: Lekac

Industrial packaging is important in brand awareness, so if you use packaging to build your brand it needs to be consistent. It helps customers determine the type of product you offer. If the product is a good product, the packaging needs to reflect that. Packaging is part of a product's advertising message.

Some important strategies to make your product look greater in market are:

| Brand Positioning

Brand positioning is about placing your brand in the minds of your customers. The aim is to identify and focus on "their" marketplace of a particular brand, product or service through a variety of strategies such as price, advertising, distribution and packaging. |

| Detailing

This means using narrative to convey a message. It is useful for everyone, from small startups to large companies. To make your target audience feel something; enough to motivate them to take action and increase their trust in your product. |

| Communicating Brand Value

Communicating value is when a business presents the advantages or benefits of its products to customers. To help potential customers become customers, companies create recommendations through advertising and marketing. |

| Trust Building

Trust marketing is a business strategy that focuses on building relationships and trust with customers. It involves creating meaningful and useful content, delivering personalized experiences, and engaging with customers through social. |

11.Reasonable Pricing for Products

Best pricing with industrial Packaging- Picture Courtesy: BOBS

With packaging goods, the pricing of products can be reduced. The pricing of products is influenced by many factors which may include pricing choice of buyers and seller. When it comes to pricing, the important thing is to find the balance between what consumers are willing to pay and the price that sellers believe is fair for their products. The idea of a reasonable price will vary from store to store and business. Ultimately, it's about making sure customers feel like they're getting their money's worth.

12.The Industrial Packaging Machines They Use

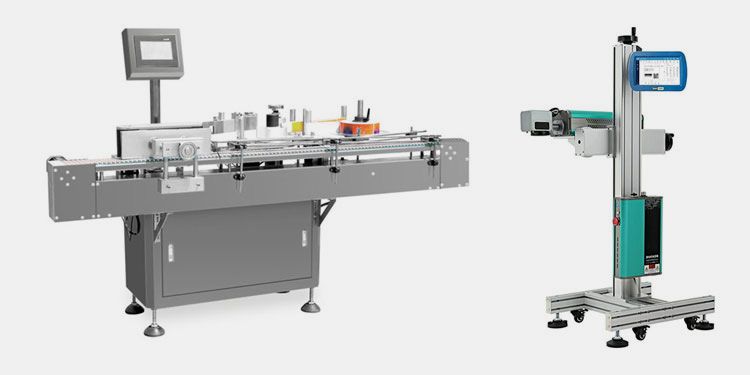

Industrial packaging machines are specialized equipment designed to facilitate and improve the packaging process of various products. These machines are used to pack good-sized products, ensuring consistency, speed and accuracy.

Some common machines used in industrial packaging are:

Allpack Filling, Sealing, Labeling, & Co2 Laser Coding Machines

Filling Machine: These machines are used to fill products into containers such as bottles, cans or bags. They can be liquid, powder or granular material.

Sealing Machine: These machines are used to create airtight seals on packages, keeping products fresh and preventing leaks. They may use different types of packaging such as bags, trays or containers.

Labeling Machines: These machines are used to apply labels to packages and provide important information such as product details, brand names or barcodes. They can be manual or automatic depending on the scale of production.

Coding Machines: They’re aimed to be utilized for assigning necessary information over the industrial packaging materials. Such as barcodes, QR codes, etc.

13.Quality of Customer Services

Customer Services- Picture courtesy: Endicia

In Industrial packaging, the quality of customer involves providing good, fast and efficient service to customers and building relationships with them. It also needs to respond quickly to customer questions and handle complaints promptly.

Good customer service can be hard to come by. Building a team that provides excellent customer service can be more difficult. That's why companies need to train customer service representatives.

Industrial packaging companies are committed to providing excellent customer service by focusing on the following key areas:

Responsiveness: It is important for industries to respond quickly to customer questions, concerns and requests. Quick response time shows that the company values its customers and is committed to helping.

Knowledge and Expertise: Customer service representatives must have in-depth knowledge of the products and services the company provides. This allows them to provide accurate information, answer questions, and offer helpful advice to customers.

Problem-solving: When issues or challenges arise, good customer service involves actively working to find solutions. Companies should be proactive in resolving problems and ensuring customer satisfaction.

Conclusion

Industrial Packaging plays an important role in ensuring that goods are transported safely and efficiently. It includes the design, materials and processes used to package products in various industries. Industrial packaging must be sturdy enough to protect the contents during transport, storage and transportation. It must also comply with safety standards and health regulations for products and workers. If you’ve any question from ‘10 Things You Should Know About Industrial Packaging’ Please contact Allpack Team now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide