10 Questions To Find Your Ideal Tablet Press

Are you planning to incorporate in your business an ideal tablet press? If yes! You might be a keen manufacturer who wants to uplift the existing production capacity. Regardless of whether you are an infant entrepreneur or an experienced person, finding the right tablet press is equally important as well as tricky. That's why, we have highlighted 10 Questions To Find Your Ideal Tablet in this review.

All these questions will enable you to take start from yourself by asking important things whose answers are given in detail. Starting from the type of material you are processing to the budget, voltage requirement and tablet press type, everything is covered. Eventually, you will be able to choose the best compatible tablet press for your production. So, let's delve deep into it!

1.What Type Of Material You Want To Process?

Various free-flowing and adhesive powders- Picture Courtesy: Syntegon

The most critical question to have an answer for is the type of material you want to process. Generally, a tablet press is able to process only solid material, however, it may have limitations on the handling of material with different properties. Similarly, the type of particles determine the speed, compression force, and other parameters of a tablet press. Thus, having clear information about your material will help you find an ideal tablet press.

To know the type of material you are running, look into the underlying explanation:

Material Size

It refers to the size of particles you are producing. These can be:

Powders: Powders are small size fine solid particulates which are commonly used to prepare tablets. Powder formulation is often used for sensitive ingredients which do not require special excipients and preservatives. So, if you are processing powders, inform your supplier to adjust the tablet press to avoid possible dust presence.

Granules:Tablet ingredients are also produced in form of granules or pellets especially for modified release drugs to enhance the drug stability and structural appearance. In such case, the particles are larger and need distinct specifications in tablet press.

Material Fluxility

Powder flowing- Picture Courtesy: stock.adobe.com

Material flow properties play essential role in the formation of tablets through distribution of particles, which can be uniform or non-uniform. It is thus eminent to study about the fluxility of your material which will enable you to use relevant technique to deal with irregularities.

Free Flowing:Free flowing material support uniform particle distribution and the granules particles are more spherical. Thus, less compression force is required to attain the stable tablets formulation.

Cohesive:In contrast, cohesive or non free flowing particles have a limitation of friction due to poor flowability. Hence, such material require special adjustment and may also need the use of granulation equipment like fluid bed granulation or shear mixer. So, make sure to test the material nature for having high-performance tablet press.

Material Sensitivity

Another aspect to know the type of material you are using, is checking its sensitivity. For example:

Corrosive:Corrosive substances may react with the tablet press during compression due to the harsh and corrosive properties present in them. For instance, the material may be prepared with hydrochloric acid, acetic acid, potassium and hydroxide. Therefore, it is inevitable to ask your vendor for a pure stainless steel tablet press which is fully corrosion resistant.

Smooth:On the other hand, for products like milk tablets, chocolate tablets, and therapeutic tablets, which do not contain corrosive substances, standard tablet press is best suitable.

2.What Are Your Requirements Of Tablet Size, Shape, And Layer?

As there are range of tablets sizes, shapes, and layers options available, you can choose the desired ones. It will make for you the selection of ideal tablet press with right tooling pretty easy. So, let's understand what are these!

Compressed tablets of various shapes, sizes, & layers- Picture Courtesy: Shutterstock

Tablet Shape

Tablet press support different shapes for tablets including round, oval, oblong, triangle, square, and special shape. These shapes are selected for several reasons such as round shape tablets are easy to swallow with small dosage. While as, for high dosage drugs delivery, bulky rod type tablets are preferred. Once done with tablet shape, you can have the machine with relevant punches such as shallow concave, deep concave, and extra deep etc.

Tablet Size

As far as the size of tablets is concerned, so, it varies from mini size to standard size and large size tablets. Small size tablets are typically of ≤ 3 mm separated into subunits of conventional tablets. Standard size tablets on the other hand, are about ≤ 5 mm in diameter. While as, large size tablets are not meant for swallowing rather they are dissolved. For instance, effervescent tablets have the largest size of 1 inch. The thickness of tablets can be measured by using a vernier caliper.

Tablet Layer

Tablets can be single layer, bilayer, or multilayer due to the different types of dosages being given in single tablet to retain their effect. Similarly, it is important for you to take note what kind of tablets you want to get. In similar fashion, you will be presented with a tablet press which is capable to support your desired tablets specifications.

3.What Is Your Desired Tablet Production Output?

Large number of coated tablets- Picture Courtesy: Shutterstock

Do you have an idea about the quantity or number of tablets which you want to produce per day or per hour? Answering this question will greatly help you to find an ideal tablet press. It is because each type of tablet press has fixed capacity of producing tablets due to technical reasons such as the speed of turret, length of punches and their diameter.

Similarly, if you have a small to medium scale production output requirement, then manual or semi-automatic tablet press will be a good choice. In contrast, for large scale production of thousands of tablets per hour, fully automatic tablet press is the ideal choice to enhance the efficiency and output of tablets manufacturing.

4.What Is The Voltage Specifications In Your Facility?

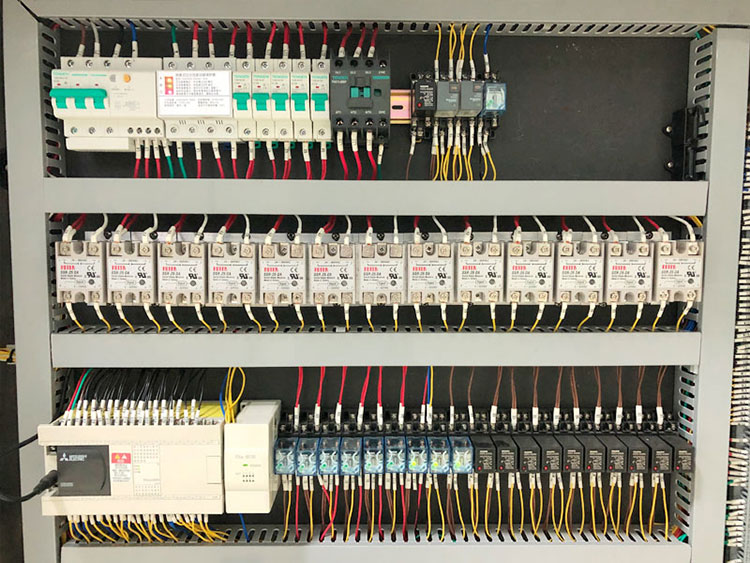

Electrical power supply system of machine- Picture Courtesy: chengyipacking.com

Tablet presses come in various specifications especially in terms of power and voltage. This electricity is solely responsible for the operation of machine and in case of voltage irregularities, it may get damage or display poor performance.

Due to this reason, it is important for you to assess the available power supply system at your facility. It will simply enable the supplier to customize the tablet press as per the domestic voltage. This can help the machine to carry out stable functioning by avoiding potential safety hazards. The voltage requirement of tablet press vary from one type of machine to another. The common examples include 110V, 220V, 380V, 415V, and 440V.

5.What Is Your Budget For A Tablet Press?

Cost icon- Picture Courtesy: bcas.co.za

While choosing a tablet press, you might be questioned by the manufacturer about your range. At that time, you may get perplexed what to answer. So, it is better to have an idea about your financial limitations and inform the vendor to present you the most compatible item.

Generally, the price of tablet press vary according to its automation level and the sophisticated structure. However, the operation cost, maintenance cost, and labor cost are also important factors which determine the final expenditure. For instance, semi-automatic tablet press is cost-effective than fully automatic one but it will require constant involvement of operator which means the need for labors.

6.Do You Have Any Specific Regulatory Requirements?

Quality assurance icon- Picture Courtesy: talentmsh.com

This is another most significant question you should have an answer for. As tablet press is meant to deal with different types of ingredients which are mostly edible and sensitive such as pharmaceutical tablets and food tablets, it must be made from food grade material. Similarly, chemical tablets are also processed by tablet press which contain corrosive substances, requiring corrosion resistant stainless steel construction.

Now, it is a matter of great concern that the tablet press must be fully safe and fit for processing your desired ingredients. For this purpose, GMP, ISO, FDA, and CE are some of the prominent regulatory standards which a tablet press should comply in order to be of standard quality. Besides this, you can also comprehend the specific regulatory compliance necessary for tablet press at your location to ensure its quality.

7.What Machine Type You Are Looking For? Single Punch Tablet Press Or Rotary Tablet Press?

Tablet press can be broadly divided into two types: single punch tablet press and rotary tablet press. Each type has its own specifications and production efficiency rate. You have to determine what type of tablet press you need between these both by looking into your production level and understanding these machines which are described below:

Single Punch Tablet Press

Allpack- TDP series Single punch tablet press

Single punch tablet press is also known as single station or eccentric press. It is the earliest form of tablet press with small footprint. The machine consists of fewer parts with single upper punch as the core component.

Similarly, it follows a straight forward working operation where the upper punch press the powder or granule into tablets, while as, the lower punch remain stationary. The equipment has capacity of compressing up to 80 tablets in a minute. Thus, it is mostly used in research laboratories and clinical trials.

Rotary Tablet Press

Allpack- Rotary tablet press machine ZP-7B

Rotary tablet press is a multi-station machine which is an advanced form of tablet press. Structurally, the machine is sophisticated and complex with heavy-duty parts, requiring large space for installation. It comprises a set of upper and lower punch for the compression of material.

Both punches continuously move through several compression stages to form tablets. Its production output capacity is quite higher with producing 800 to 8200 tablets per minute. This machine is suitable for large scale production facilities.

8.What Feeding System Do You Require? Opened Or Closed?

Feeding system play a key role in regulating the flow of powder and granules into dies. It affects the tablet formulation from particles flowing frequency and tablet press compression efficiency to the finished tablets properties including weight, thickness, and dissolution timing. Each tablet press is equipped with specific feeding system which can be broadly categorized into open feeder and closed feeder:

Tablet press feeder- Picture Courtesy: LFA Machines

Open Feeder

Open feeder is also called gravity feeder which is fitted in most of the tablet presses. It flows powder and granules through gravity, therefore, does not involve mechanical tools for material feeding. The steady flow of particles help in reducing the irregularities in tablet weight. However, such type of feeding system is only useful for free flowing particles and not suitable for cohesive powders which are prone to bridging. Hence, its flow of material is slow.

Closed Feeder

Closed feeder, on the other hand, has a screw or auger system fitted inside it to efficiently feed the material from hopper into the dies. However, its feeding mechanism follow two steps where first the material is drawn from hopper into a collection bin after which precise dosage is infused into dies. It is perfect for maintaining the weight of non free flowing particles as well as enhancing the material flow efficiency.

9.What Tooling Size You Are Looking For?

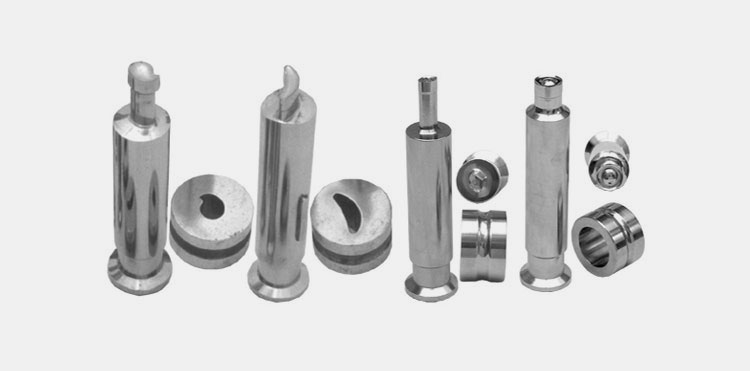

Tooling is the core component responsible for determining the size and shape of tablets. These tooling simply include the dies, upper punches, and lower punches which can be classified as type B or type D. To understand these tooling and their compatibility to your production, consider the underlying explanation:

Dies & punching tooling of tablet press- Picture Courtesy: shaktipharmatech.com

Type B Tooling

B type tooling is widely used tablet tooling due to its standard specifications for tablet sizes such as die diameter, punch head, and tablet hardness. It is characterized by the round die along with concave upper and lower punch. It produces tablets with convex face. B type tooling is best for high-volume tablets manufacturing due to its versatility in making wide range of tablets sizes and compatibility with different compression machines.

The diameter of the B tooling punch is ranged with 30.16mm or 1.1875 inches and it gives 20 to 25% greater production output than other tooling.

Type BB Tooling

This tooling with diameter of 24mm or 0.945 inches are used for tablets compressions required diameter of 9mm till 11mm.

Type D Tooling

D tooling is another popular standard for tablets formulation which is known as European Tooling. Unlike type B tooling, it has a set of die with flat upper and lower punch. This type of tooling is preferred for making special tablets like effervescent tablets, scored, or bilayer tablets. It offers flexibility in tablets design and ,therefore, good for small scale manufacturing.

The tooling diameter of this type ranged with 25.4mm with mold diameter of 38.10mm. For making of large length tablets, thus this is preferred.

Type DB Tooling

This tooling can be established when D tooling is utilized for the compression of tablets with B tooling compression machine. that’s why it is known as DB tooling. It has barrel diameter ranged with 0.75 inches following length of 5.25 inches.

On the basis of tablet sizes, the following below tooling system is classified.

| Tooling Types | Punch Barrel Diameter in inches | Punch Head Diameter in inches | Outer Diameter of Die in inches | Length in inches |

| D | 25.4mm | 1.25 | 38.10mm | 5.25 |

| B | 19.0mm | 1 | 30.16mm | 5.25 |

| BB | 19.0mm | 1 | 24.00mm | 5.25 |

| DB | 25.4mm | 1 | 30.16mm | 5.25 |

10.What Maintenance Requirements Does The Tablet Press Have?

Maintenance icon- Picture Courtesy: gesrepair.com

Regular maintenance is crucial to prevent spontaneous breakdowns and increase the working life of a tablet press. Similarly, you must have proper knowledge regarding the maintenance schedule of the type of tablet press you want to purchase.

Generally, every tablet press require cleaning on regular basis to remove out the residues and accumulated dust. It simply keeps the machine hygienic for processing materials. Moreover, lubrication of movable parts, the changeover of damaged parts and structural adjustment are other aspects which vary from one type of machine to another. So, make sure to get the know-how of the maintenance requirements of the concerned tablet press.

Conclusion

Gone through the 10 Questions To Find Your Ideal Tablet Press? Well, the answer is probably yes! Understanding these questions properly can greatly help you refine a top-notch tablet press for your production. In addition, the nature of material being used, output ratio, type of tooling, and quality compliance requirements are what are needed for making a vigilant decision. Once paid heed, you won't be bothered to regret your decision and will simply enjoy the performance of compatible tablet press. If you are looking forward for top a class tablet press, Allpack is offering the best one! For further information contact us through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide