10 Maintenance Tips And Solutions For V Blenders

Looking for professional maintenance tips and solutions for your V blenders? Finally, you have made it! Maintenance is inevitable to keep your V blenders at optimal working condition. Unfortunately, most of the new users do not pay attention to routine schedule which leads them to regret only.

If you are also struggling with the same problem or wishing to gather knowledge about the routine maintenance and troubleshooting of v blenders then this post about 10 Maintenance Tips And Solutions For V Blenders is for you. Make sure to give it a thorough read and follow the steps!

1.Clearly Check The Parts Of Blender.

Allpack- VH-50 V type mixer

As we know, that blender is composed of several components, so, each component play key role in the overall functioning of blender. Now, these parts vary from movable V bin and shafts to the stationary main frame, electric box, control panel, and valves. What you need to do is to clearly check these parts of blender and locate them in before you start operation.

For this, you can move the bin manually to check whether it is moving smoothly without any resistance. Similarly, parts like inlet and outlet valves should be tightened well to make sure material is not leaking. It is also important to check the electrical components of blender such as control panel, emergency stop, and wiring by ensuring that they are in working condition and do not exposed.

2.Adhere To Preventive Maintenance Schedule.

Preventive maintenance- Picture Courtesy: gottsteincorporation.com

Preventive maintenance simply refers to follow a routine maintenance for your V blender before it starts showing any kind of damage. Thus, make sure to properly calibrate your machine and conduct its servicing every week.

Install the V blender in a place which is well ventilated, especially, if you are dealing with any kind of product with unfavorable smell or hazardous particles like that of spices and chemicals. Moreover, the alignment of different components and integration of auxiliary machines can also help in the stable performance of your V blender, ultimately reducing the chances for damages.

3.Understand Your Spare Parts List.

Spare parts- Picture Courtesy: wuling.id/en

Spare parts are what we call duplicate parts which are meant to be replaced with the broken or old part of any machine. Similar is the case with V blenders which also need relevant spare parts for frequent changes if any part gets defected.

That's why, it is very essential for you to understand the spare parts list for V blender and make sure their availability in your inventory. By keeping these tools at hand can significantly minimize the equipment downtime and optimized maintenance costs.

Thoroughly studying the spare lists and their usage will also enable you to track the location of error and correct it by yourself for smooth functioning of the machine.

4.Observe The Noise During Operation.

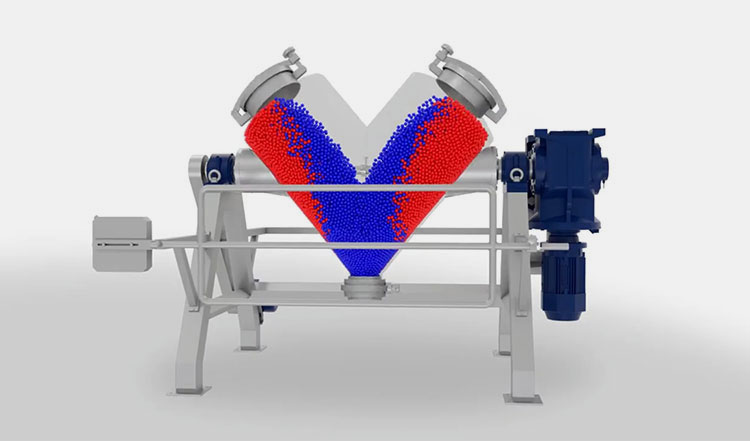

Allpack- V blender VH-2 mixer

When operating V blender, you need to be attentive enough to observe every single sound that it generates. It is important for the reason that your V blender will only create noise during operation if there is any sort of disturbance or something is going wrong.

In case you found your blender with abnormal noise when mixing, just try to identify the location. It can vary from the sound of friction of sprocket to the unusual rotation of overloaded V bin and shaking body. Once you have successfully identified the place, it will be easy to troubleshoot the irregularities.

5.Replace Worn-out Parts.

Operator maintaining machine- Picture Courtesy: technotes.alconox.com

It is certain that your V blender may display downtime at any point during its working life, it simply means that a part of it is being defected or worn-out. Now, it is time for the changeover of such parts with new functioning one.

For instance, seals, bearings, and gaskets are some of the common examples of parts which are frequently prone to wear and tear. Thus, timely replacing damaged parts can protect your V blender and prevent unexpected breakdowns during operation.

6.Keep The Blender Lubricated.

Lubricating movable parts- Picture Courtesy: advancedtech.com

Proper lubrication of the movable parts of your V blender is vital for its uninterrupted and smooth functioning. It reduces the parts friction and possibility of wear and tear. It is thus necessary to understand the types of lubricants suitable for the machine which can be easily found in user manual or maintenance guide.

While selecting lubricants, make sure to use only specified lubricants recommended by the manufacturer which can be in form of oil or grease. Before applying lubricants, make sure to clean the joints, bearings, and surrounding areas for removing out accumulated dirt and residues.

When lubricating, it is crucial to properly apply greasing agent to the desired area while using a clean brush or spray bottle. During application, try to avoid over lubrication as it can lead to the creation of dirty lumps due to attraction of debris, ultimately affecting your blender.

7.Monitor The Mixing Process.

PerMix V Type Mixer- Picture Courtesy: PerMix

Your actual task begin when finally the v blender starts working. Now, you need to visually monitor the mixing process and keep checking the various parts of machine during operation such as impeller performance and bin movement.

It simply includes examining the lights and indicators on control penal, checking for loose bolts, unusual vibrations, and signs of wear etc. Assessing these problems promptly can prevent their escalation into major issues.

8.Clean The Blender After Use.

Liquid cleaning agent bottle in hand- Picture Courtesy: popularmechanics.com

Cleaning and sanitization is inevitable for maintaining the hygiene and longevity of V blender. That's why, proper cleaning schedule should be followed each time after using blender in order to keep it free from unwanted contaminants and bacterial presence.

Generally, the cleaning of V blender can be classified into two phases:

Internal Cleaning:It involves washing down the internal parts of machine such as twin shell, impeller, and cover assembly. These components should be regularly wash down by using non acidic water with recommended cleaning agents.

External Cleaning:External cleaning usually involves the wiping of exterior body of the blender including main frame, control panel, and touch screen display. For such parts, mild damp cloth can be used to disinfect the surface against bacteria and dust.

Steps for cleaning

Shut down the blender by disconnecting electric source.

Disassemble the parts which are meant for washing which are usually internal components like v bin and lids.

Wash these parts while using recommended means.

Once the cleaning is done, properly dry the parts through soft clean cloth.

Now, assemble the cleaned parts by installing them on their exact locations.

9.Keep Updating The Blender Setting.

Allpack- VH-2 mixer

V blenders are automatically operated equipment which works through proper mechanism of control system. This control system is itself executed by the softwares and parameters which are fixed by operator such as the speed of agitator and time for each cycle of bin rotation.

Now, the setting of blender must be updated each time when using the material of different nature such as granules, powders, free flowing, and cohesive substances. It simply includes updating softwares, parameters, and other structural adjustment of tools. Skipping, this important step might leave you with unsatisfactory results in form of nonuniform output and even stagnation of the machine.

10.Train Your Employees.

Employee training- Picture Courtesy: mbimybigidea.com

Last but most important tip that must be followed for V blenders is the training of your employees. After all, they are the actual operators of your machines, so, they should be well trained to understand the different components of blender and how each part is performing its role.

Moreover, gaining practical knowledge of the blender's maintenance requirements and structural adjustment will help them better deal with the spontaneous complexities of machine caused during operation. Thus, you will not be bothered to ask for outdoor professional support when the same trained staff would be serving at your own facility.

Troubleshooting Of V Blenders

The nature of V blenders, which are machines, can be better understand if they are compared to humans. Both utilize their energies to perform particular tasks but during their discharge of performance, they may get stuck. Now, it does not show their failure rather it is referred to as a barrier or obstacle which need proper channel to be solved. This process is simply termed as troubleshooting, finding the root cause and employing relevant technique.

In underlying explanation, you will know the common issues of V blenders along with their possible causes and solutions. So, stay tuned to understand these all!

Material Leaking

Allpack- VH-14 Mixer

The powder or granules inside V shell is leaking from either or both the outlet and inlet.

Cause:

The outlet buckle is loose.

The seals of inlet and outlet assembly are ageing.

Solution:

Removed the buckle and fix it in right position.

Change the sealing ring with new one.

V Blender Not Working

V blender with highlighted faults- Picture Courtesy: sedpharma.com

V blender is not moving even after it is started.

Cause:

Opened protection cover.

Rotation speed is inappropriately settled.

Poor connection with electricity.

Solution:

Close the protection cover each time before starting the blender.

Adjust the revolving speed of V blender through control panel.

Check the power connection and supply of voltage.

Abnormal Noise

Noise icon- Picture Courtesy: dpamicrophones.com

V blender is causing abnormal noise during operation.

Cause:

Missing foot pads.

V blender is positioned on uneven surface.

Main shaft is shaking due to improper fixation of screws.

Rough rotation of V-shaped cylinder.

Solution:

Add food missing foot pads.

Locate the machine on flat surface.

Fix the shaft by adjusting screws.

Check and adjust the cylinder through tightening screws.

Inconsistent Mixture

Encircled paddle- Picture Courtesy: phxequip.com

Ingredients processed by the V blender are not uniformly mixed.

Cause:

The V shell is overloaded.

Mixing time is insufficient.

Slowly rotating V bin.

The agitator used in V blender is not compatible to the ingredients processed.

Solution:

Reduce the material loaded into V bin and left 1/3 place unfilled.

Increase the mixing time.

Speed up the rotating V bin through control panel.

Install mixing paddle in accordance with ingredients characteristics.

Conclusion

To put in a nutshell, the above explained 10 Maintenance Tips And Solutions For V Blenders can play instrumental role in keeping your V blenders on right track. Always remember, that preventive maintenance, parts changeover, lubrication and regular inspection of the machine are key to stabilize functioning of your machine. In addition to it, understanding the possible spontaneous breakdowns of machine can also help you timely take the counter measures for solution. So, if you found this review helpful, stay tuned for other such posts!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide