Processing and packaging solutions

As one of China largest processing and packaging manufacturer with over 10 years’ expertise, ALLPACK is committed to quality, service, and one-stop solution providing. By looking deeply into customers’ demands and competing with the current method or processing and packaging, our engineers strive to develop advanced technology and innovative technologies and sustainable solutions.Through providing you sustainable solutions, we support you in switching to alternative processing&packaging machinery and resource-conserving production process.

ALLPACK offer high-quality manual, semi-automatic, and full automatic processing and packaging machines for small to large industrial needs.

Why Choose ALLPACK: Our Advantages

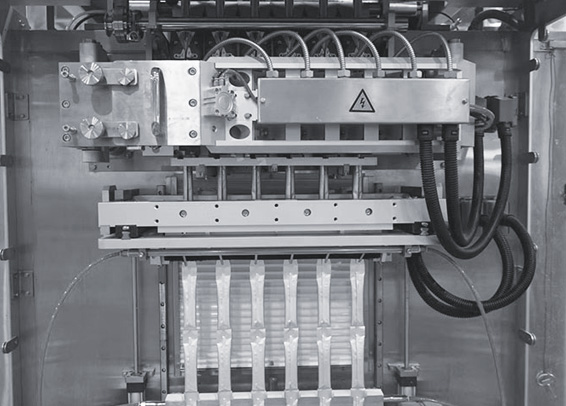

Automatic Intelligent Manufacturing

We keep quality control from beginning to end & full traceability of all machines quality throughout the manufacturing process.

Well-selected Raw Materials

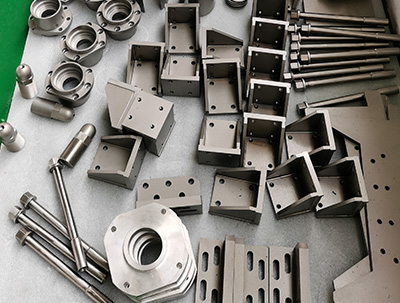

Parts Processing & Inspection

Exquisite Hand Assembly

Careful Machine Inspection

Strict Trial & No-load Test

Final Polishing & Packaging

Processing and packaging solutions for your industry

Food

ALLPACK has supported food industry with processing and packaging machineries for more than 10 years. Different food ingredients may have different packaging styles. Due to versatility of ALLPACK processing & packaging machines, you can handle a wide range of different products and containers through the same machine with minimal change-over times, and all these pack styles can also strive for sustainable packaging solutions.

Pharma

ALLPACK is one of China leading pharmaceutical processing&packaging machineries supplier.Though pharmaceutical industry demands the highest standards of quality in design, accuracy, GMP, stability,materials,security,etc. ALLPACK insist on the same quality ever since its foundation.Whatever your demand, we could meet your various requirements from pharmaceutical solid, semi-solid and liquid processing and packaging.We could also provide fill validation documentation to support our machines validation and compliance.

Chemical

Filling machines for chemical and agrochemical products need high quality materials that will not be degraded by potentially aggressive products, ALLPACK chemical filling machines from frame material to contacts parts ensure the property of your filling products not be affected. Chemical products that ALLPACK have supplied equipment include bleach, shampoo, lubricant oil, flammable and explosive liquids and pesticide liquids filling.

Cosmetic

Cosmetic industry covers a large sector products in our daily life from skincare, haircare, make-up, perfumes, toiletries and oral cosmetics. ALLPACK offers various number of processing and packaging solutions for cosmetic products, from semi-solid mixing, filling, sealing, labeling and packaging. We could also customized your production line and integrate new machines into your existing lines and provide you with online training, technical support and various qualification and validation documentation.

Nutrition

To receive adequate, appropriate nutrition, people need to consume a healthy diet, which consists of a variety of nutrients—the substances in foods that nourish the body. As the ever-fast rhythm of the society, it is mostly hard to take enough nutrition from the food taken every day,so more and more people prefer to some extra nutrition like capsule, tablet or protein supplement,while ALLPACK could provide many solutions for this ever-growing market. ALLPACK machines could give you high accuracy filling and minimum product wastage.

Agricultural

Agricultural industry involve a lot of food or crops for consumption purpose.With over 10 years’design and manufacturing experience, ALLPACK have developed large numbers of production lines of filling machines, for 10 to 100L containers that handle fertilizers, insect control chemicals, weed control chemicals and many other agricultural products.

years of experience

patents and patent applications

machines installed world-wide

locations

Our customers are also interested in

Get Your Free Quote Today

FAQ