Introduction:

BS-1230 series label shrink tunnel adopts hot air circulation for shrinking, is mainly used for shrinking labels of bottles

jars and cups etc., no matter the label is on the body, bottom or cap of the bottle.

Features:

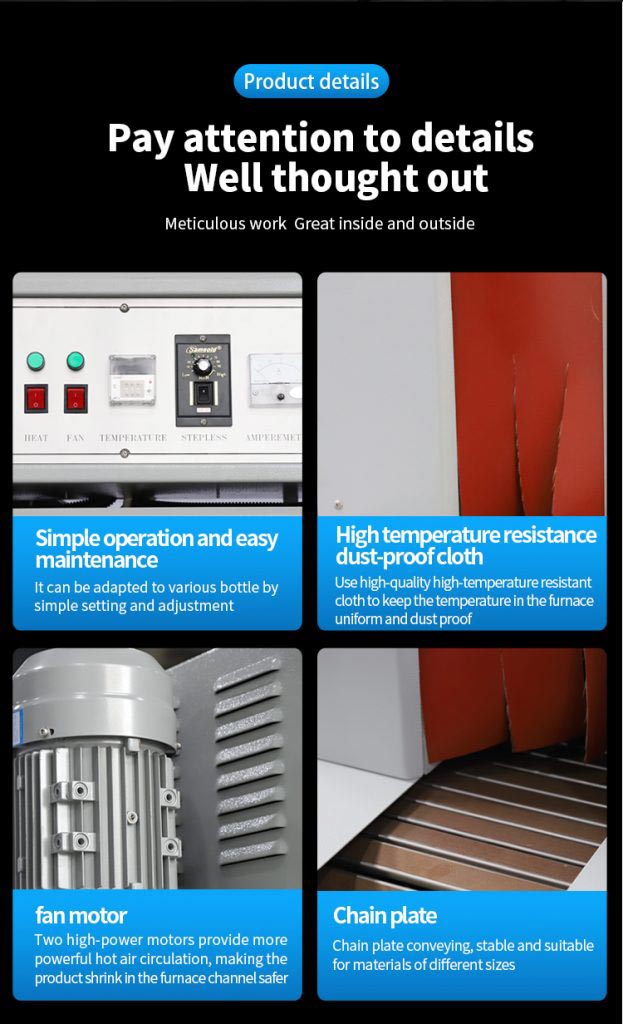

Adopt high power blowing motor and turbine for air blowing, which will not cause the label to change position or become deformed. Simple changeover for different kinds of bottles.

The heater made of stainless steel has long used life.

The shrink temperature can be regulated according to the requirements of the package at will, up to 300°℃. Adopt stepless conveying speed regulation controlled by electronic speed governor.

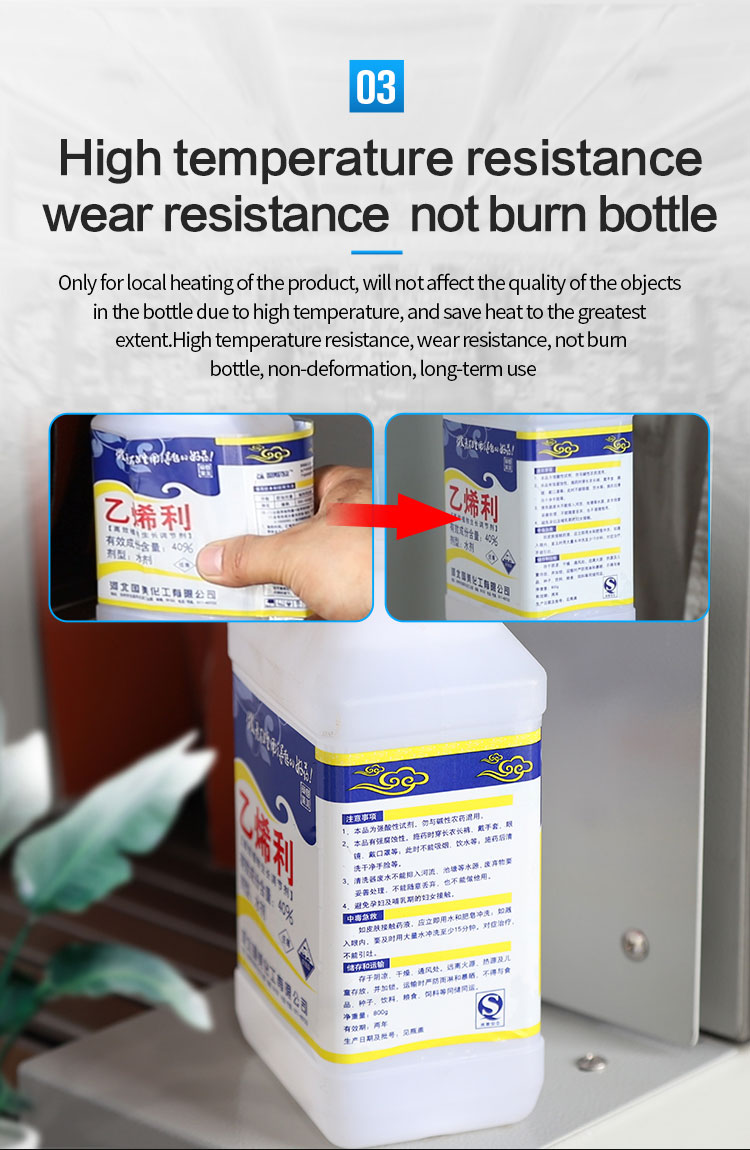

only the cap parts of bottle is heated, so the quality of product inside the bottle will not be affected due to high temperature.Tunnel can be heated partially according to some special requirement of the products in order to save energy.

The machine can be operated alone or connected with the production line.

Application:

BS-1230 series label shrink tunnel is widely used in industries such as foodstuff, beverage, pharmacy, cosmetics and

pesticide for containers with labels like glass

bottle, plastic bottle, paper cup etc.

Product Detail:

Specification:

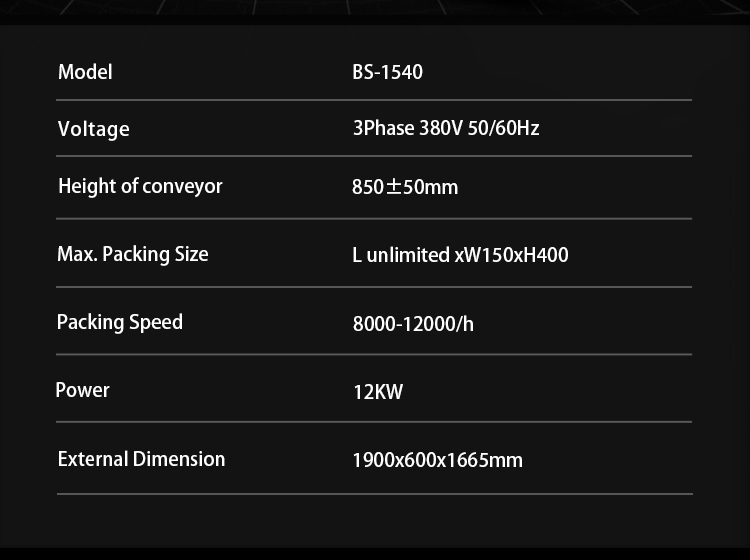

| MODEL | BS-1540 |

| Voltage (VIHz) | 380/50 (3P) |

| Power (kw) | 14 |

| Max. Packing Size(pxH)(mm) | 140×350 |

| Packing Speed (pcs/hour) | 8000-12000 |

| Tunnel Size (LxWxH)(mm) | 1600×150×400 |

| External Dimensions (LxWxH)(mm) | 1900×600×1665 |

| Net Weight (kg) | 300 |

Reviews

There are no reviews yet.